Small flexible winch coiling device

A smart, over-discharge technology, applied in the field of small and smart hoisting and over-discharge devices, can solve the problems of large space, bulkiness, and large shape of the reel box, and achieve the effect of strong practicability and reducing space restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

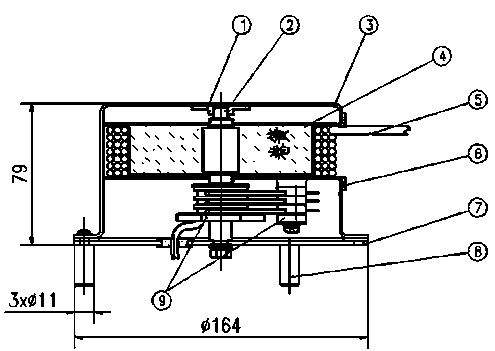

[0008] by figure 1 Known, a small and smart winch over-discharge device, consisting of a center seat 1, a central shaft 2, an upper cover 3, a winding seat assembly 4, a covered wire 5, a window sheath 6, a bottom cover 7, a mounting seat 8, an electric The brush assembly 9 is composed of the center base 1 and the upper cover 3 connected by spot welding; the winding base assembly 4 has the following parts connected by spot welding: winding base Ⅰa, winding base IIb, brush mounting plate c , D pressure line piece. The coil spring is fixed on the central shaft by copper rivets; the window sheath 6 is fixed with the upper cover 3 by AB glue. The left half of the brush assembly 9 has bakelite cover, bakelite spacers (3 pcs), and iron washers (4 pcs) from top to bottom, which are fixed on the 4, winding seat assembly by round-head Phillips screws M5X30. c Brush mounting plate; the right half has slip ring seat, slip ring (3 pcs), spacer (3 pcs) fixed on the threaded end of the cen...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap