Three-point bending supporting device based on dynamic fracture toughness of test material

A technology of fracture toughness and three-point bending, which is applied in the direction of testing the strength of materials, measuring devices, and analyzing materials using one-time impact force, can solve the problems of bulky and bulky structures, inconsistent test results, unfavorable disassembly, replacement and maintenance, etc., to achieve Ensure fixed-point force resistance and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

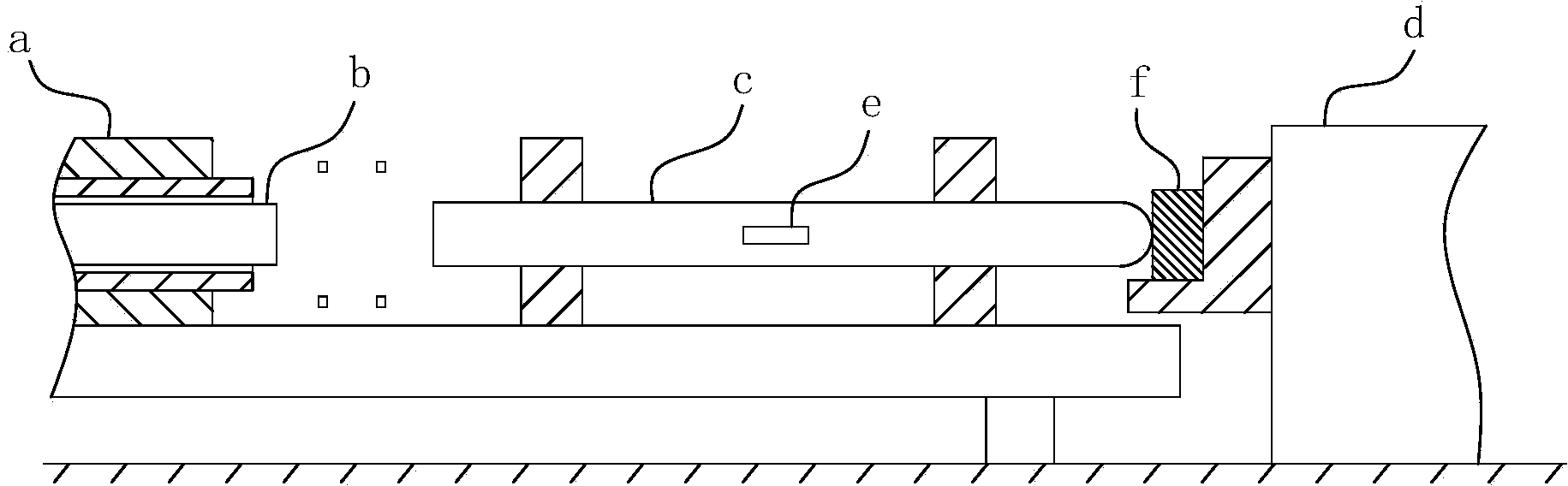

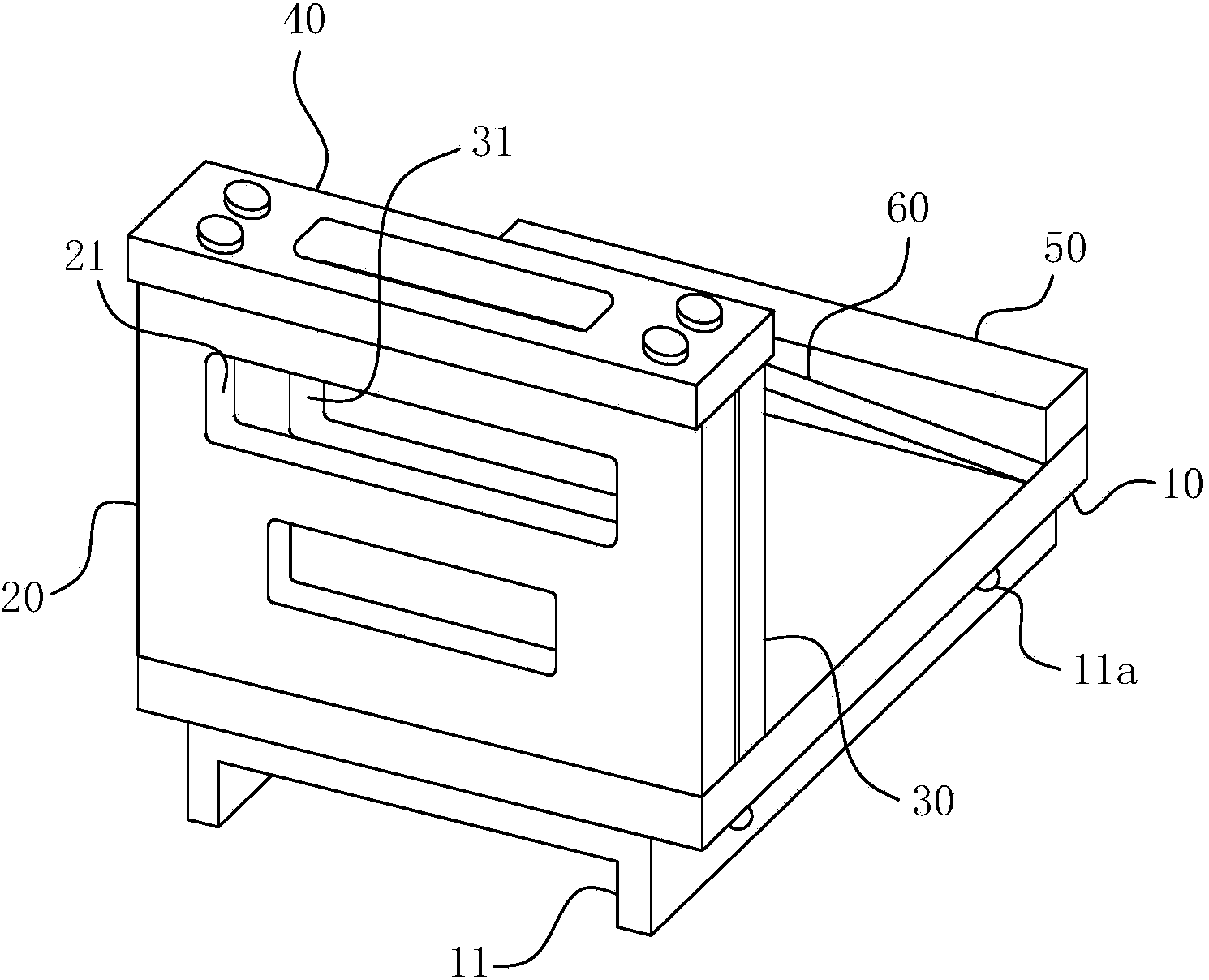

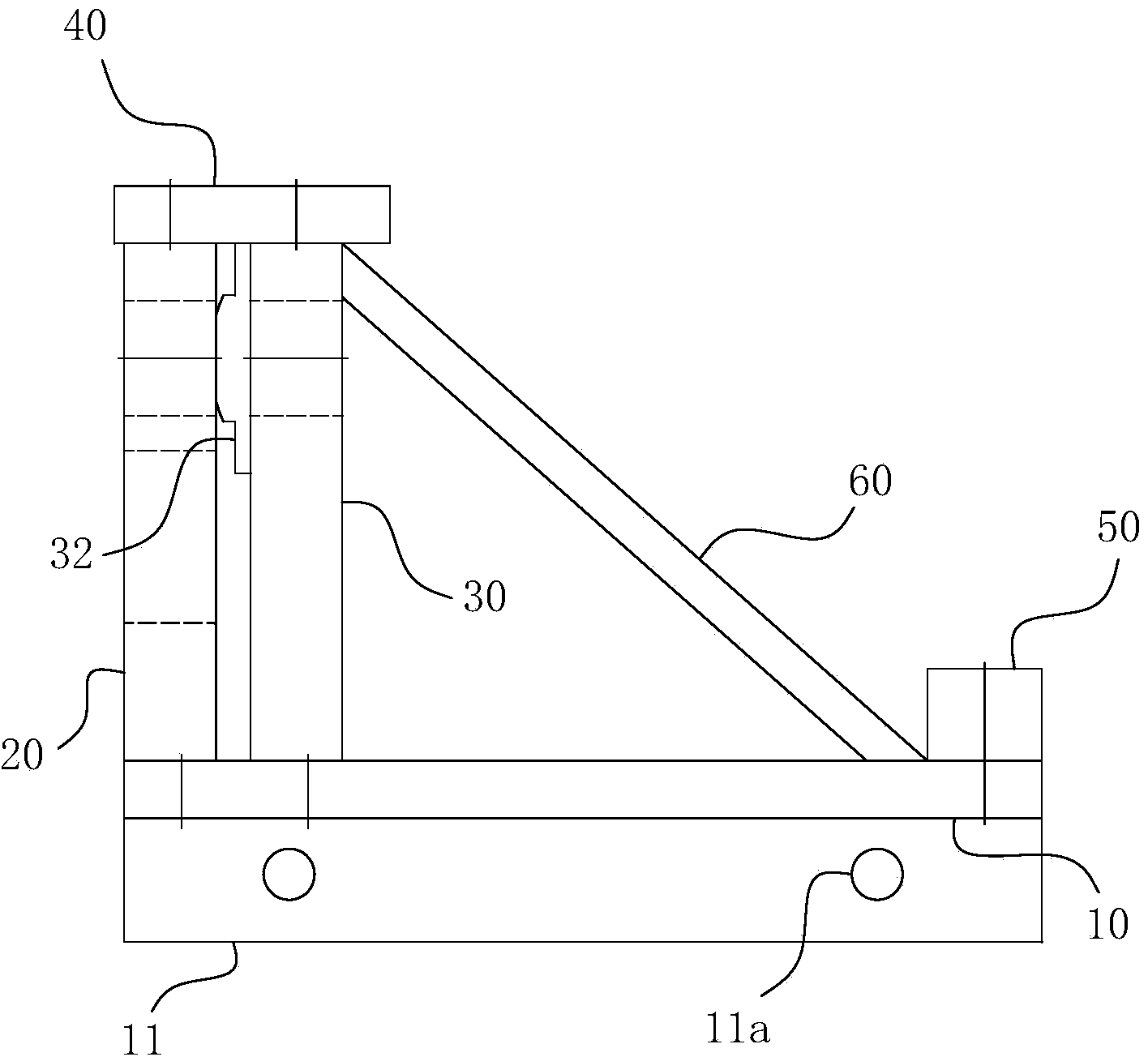

[0047] combine here Figure 2-19 Concrete structure and workflow of the present invention are described as follows:

[0048] The specific implementation manner of this device can be divided into two kinds according to the actual situation, respectively as follows:

[0049] one, such as Figure 2-11 and Figure 14-19 As shown, it specifically includes a base plate 10 provided with bottom grooves, the base plate 10 and the external guide rails of the entire system are fixed in advance with guide rail grooves 11, vertically arranged vertical plates 20 and liner plates 30 parallel to each other on the base plate 10, the vertical plates 20 is used as the supporting part of the sample to be tested, on which a rectangular through hole 21 is arranged through the plate body for placing the sample, and the backing plate 30 is used as a pad part, on which the through hole part 31 is also concentrically arranged, and in the through hole Detachable pads 32 of independent structure are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com