Stress surface variable piston

A force-bearing surface and piston technology, used in non-mechanical drive clutches, fluid drive clutches, clutches, etc., can solve the problems of limited ability to improve clutch control characteristics and limited ability to quickly fill oil, and achieve reduced impact and mixed elastic modulus. Small changes and the effect of improving control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings and examples.

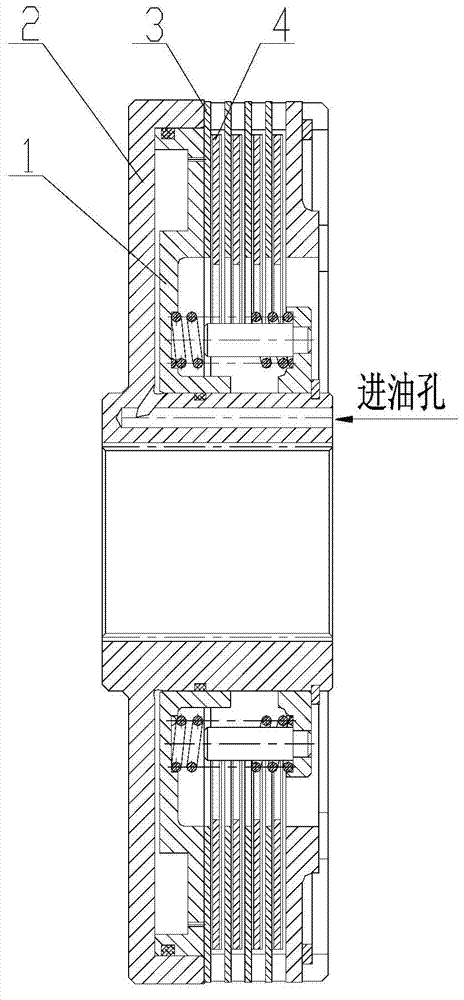

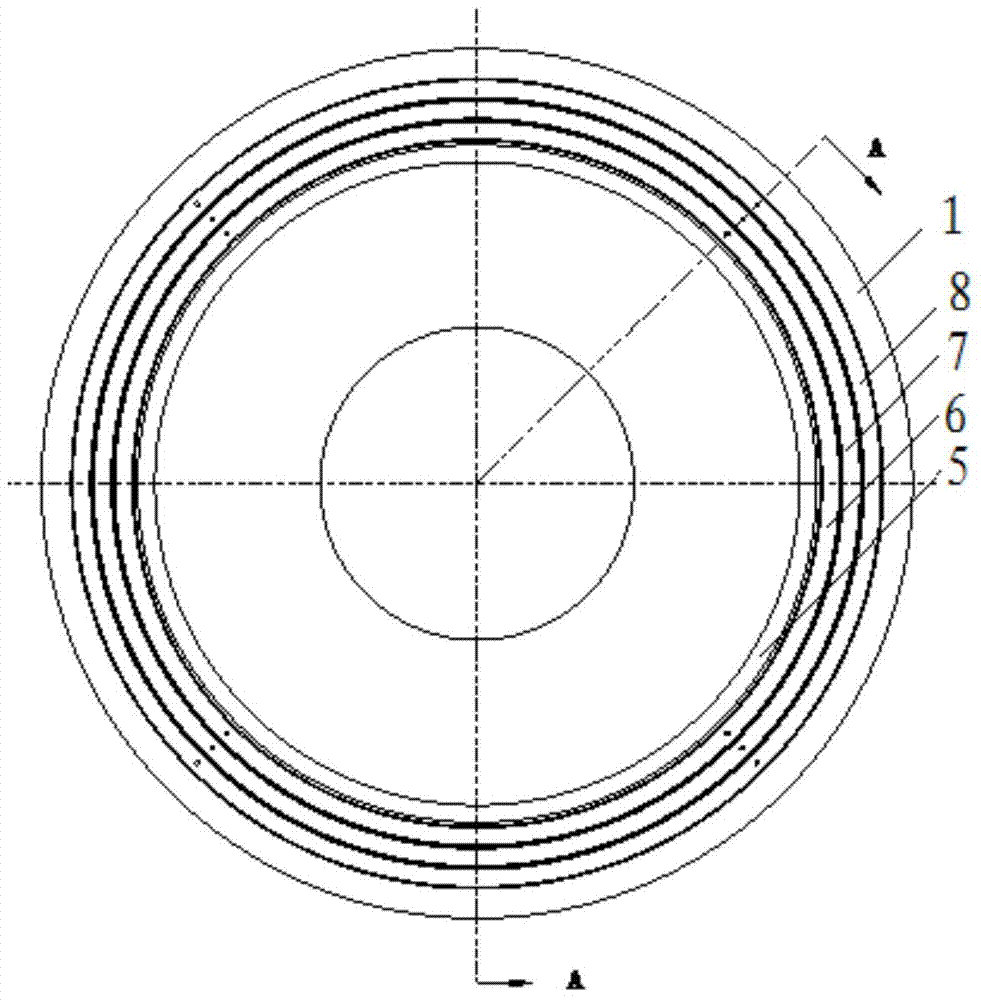

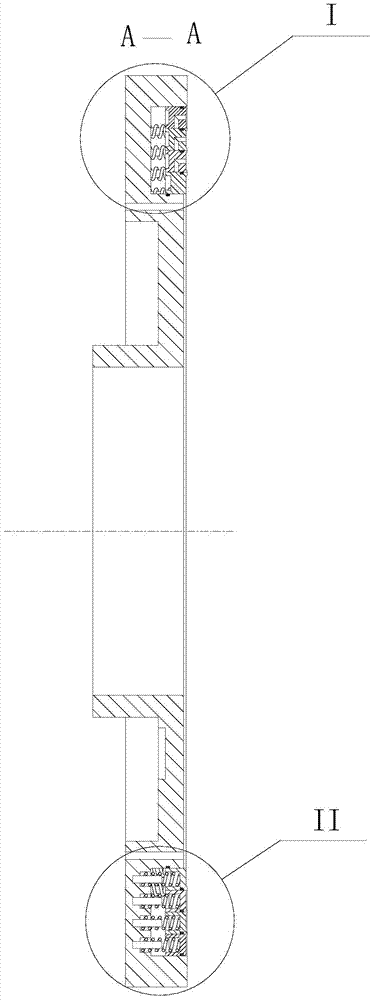

[0025] as attached figure 2 , 3 As shown in and 4, the present invention provides a piston with variable force bearing surface, including a piston body 1, a piston ring set, a spring 9 and a positioning pin 10; wherein, the piston ring set includes a piston ring I5, a piston ring II6, a piston The diameters of ring Ⅲ7 and piston ring Ⅳ8, piston ring Ⅰ5, piston ring Ⅱ6, piston ring Ⅲ7 and piston ring Ⅳ8 increase sequentially, and the end faces of the two ends of piston ring Ⅰ5 are the working surface and the installation surface respectively. The plane from the edge and concave, the plane extends to the inner circumferential surface of piston ring Ⅰ5; the working surface of piston ring Ⅱ6, piston ring Ⅲ7 and piston ring Ⅳ8 is the bottom surface of the annular groove on the end surface, piston ring Ⅱ6, piston ring L-shaped oil holes 11 are processed on Ⅲ7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com