Cable sleeve

A technology of cable bushing and semi-cylindrical tube, applied in electrical components and other directions, can solve the problems of narrow structure and installation space, difficulty in erecting and aligning steel pipes, and difficulty in penetrating into the mechanism box, so as to increase safety and reliability and avoid insulation performance. Drop or even short circuit, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

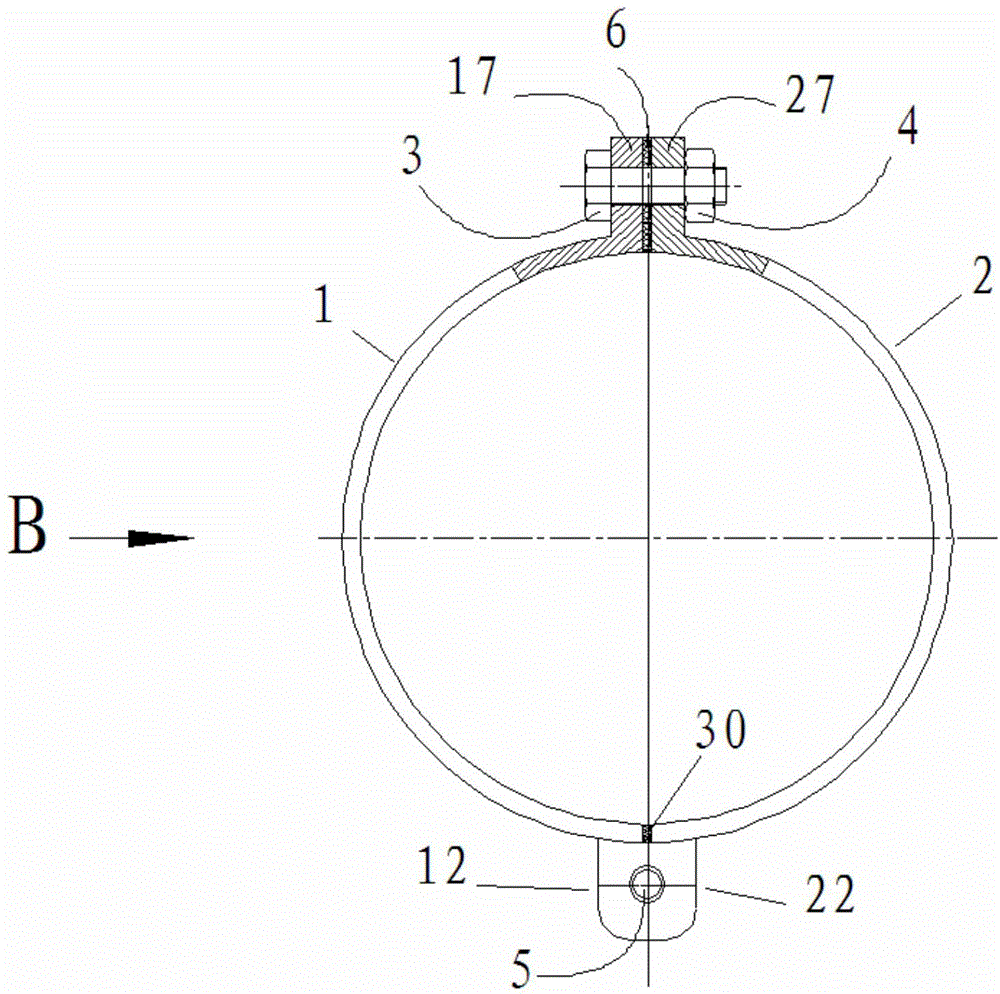

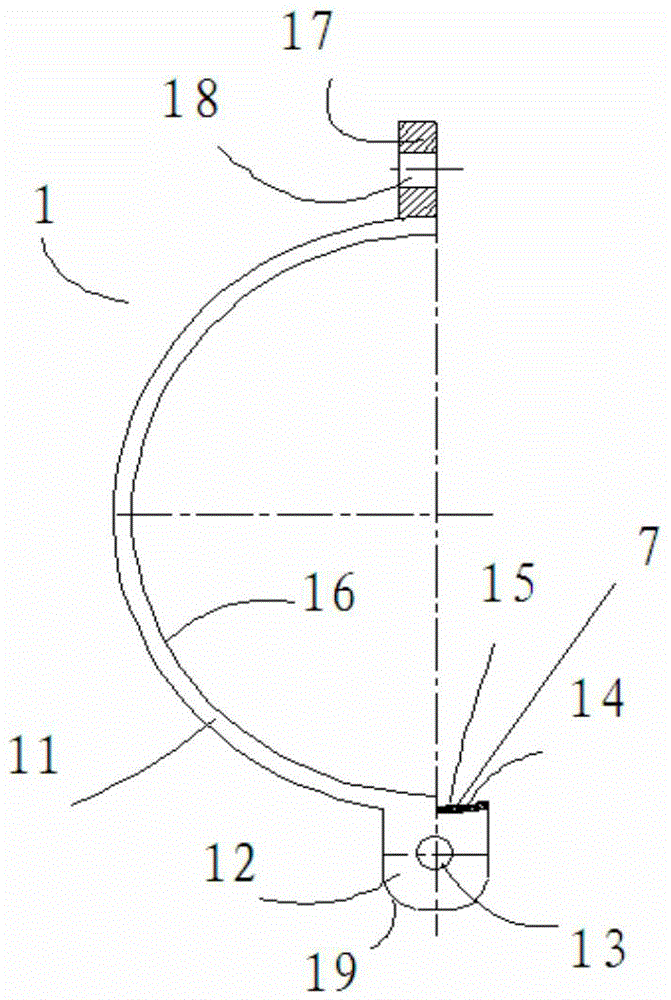

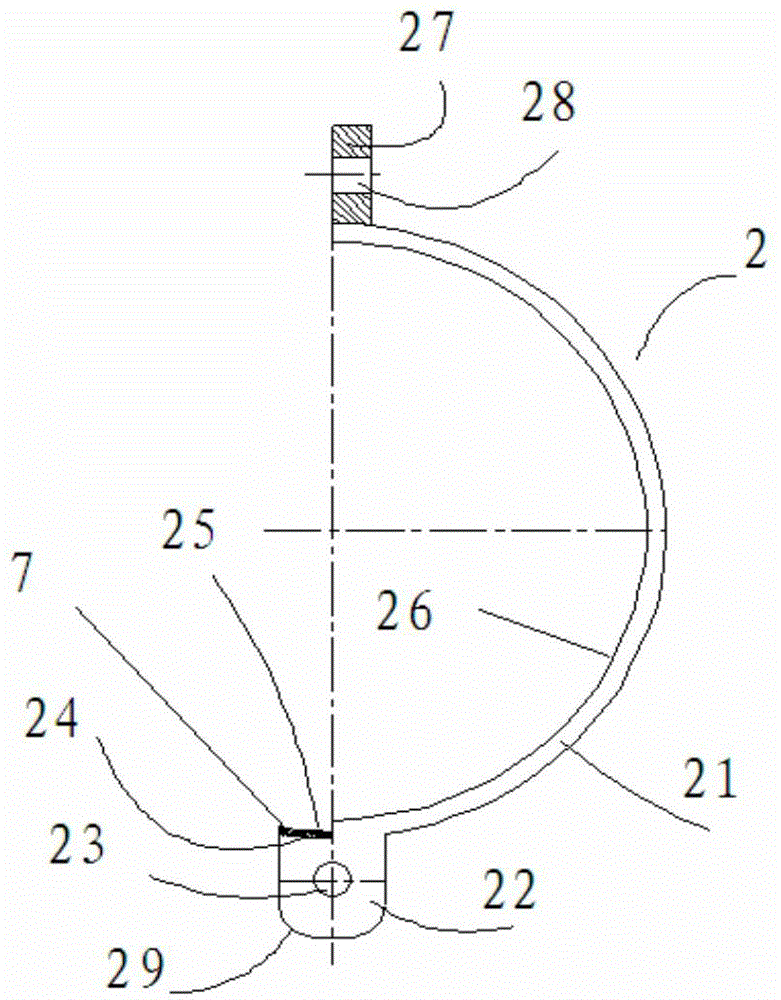

[0023] combine Figure 1 to Figure 5 , a cable sleeve, comprising a first semi-cylindrical tube 1 of equal diameter and a second semi-cylindrical tube 2 connected, the opening position of the lower part of the first semi-cylindrical 1 is provided with a first outer cylindrical surface 11 connected The first fixing plate 12, the first fixing plate 12 is provided with the first connecting hole 13 parallel to the axis of the first semi-cylindrical tube 1, the opening position of the upper part of the first semi-cylindrical is provided with the first connecting hole 13 connected with the outer cylindrical surface A connecting plate 17, the first connecting plate 17 is provided with the third connecting hole 18 perpendicular to the axis of the first semi-cylindrical tube 1; The second fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com