Automatic feed mechanism

A technology of automatic feeding and forehearth, applied in the direction of automatic in/out of workpieces, automatic/semi-automatic lathes, mechanical equipment, etc., can solve the problems of blank congestion, complex control system, poor production continuity, etc., to achieve simple control system, system Good stability and avoid the effect of poor production continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

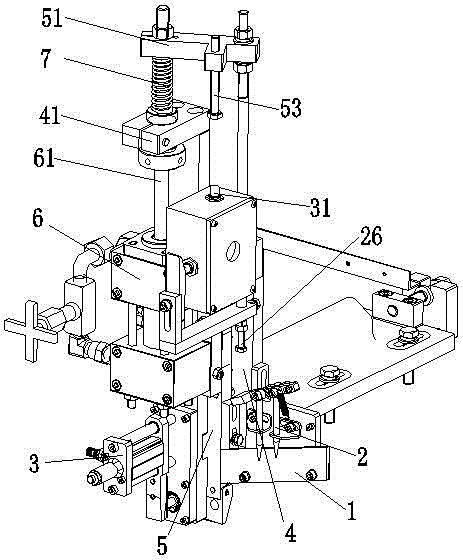

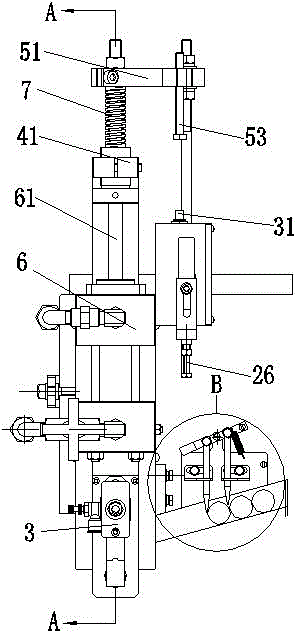

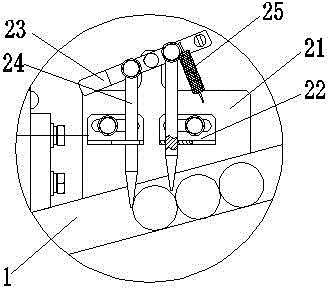

[0023] The automatic feeding mechanism of this embodiment will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

[0024] A kind of automatic feeding mechanism of this embodiment, such as figure 1 , figure 2 , Figure 4 As shown, it includes a material channel 1, a fixed support 4 and a movable support 5. Wherein, the movable support 5 is slidably connected with the fixed support 4 in the vertical direction, and the way of the slidable connection adopts any one in the prior art that can realize relative sliding up and down.

[0025] The lower end of the above-mentioned movable support 5 is provided with a pressing device 3 for pressing the workpiece into the lathe clamping device. The inlet connected to the road 1 and the outlet corresponding to the clamping device of the lathe, the outlet of the above-mentioned material chamber 52, the axes of the clamping device of the lathe and the pressing device 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com