Fluidized fluidized bed bed structure that can perform winnowing and drying at the same time

A fluidized bed and bed technology, which is used in drying solid materials, drying gas arrangement, heating to dry solid materials, etc. Reasonable, fully and evenly dried, without the effect of dead zone of material storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

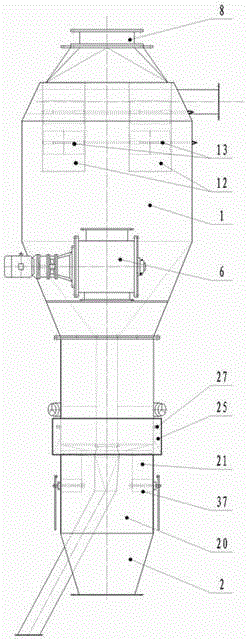

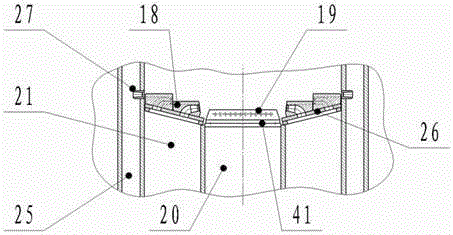

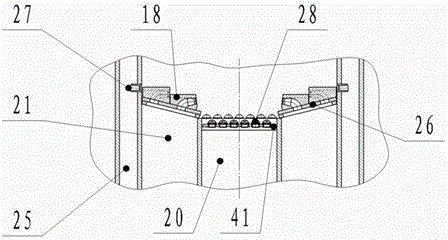

[0030] a kind of like Figure 1 to Figure 8 The fluidized fluidized bed structure of the present invention that can carry out winnowing and drying at the same time includes an outer shell 1, four segmented air chambers 2 and air distribution plates 3; the outer shell 1 and the air distribution plates 3 are coated to form a Fluidized bed chamber. The fluidized bed chamber is mainly composed of a front chamber 4 and a rear chamber 5 , and the front chamber 4 and the rear chamber 5 are separated by a chamber partition 9 . Such as figure 2 As shown, the cross-sections of the front cavity 4 and the rear cavity 5 are fusiform (that is, the middle section is wider and rectangular, and the two ends are gradually narrowed), that is, the upper, middle and lower parts are trapezoidal, rectangular and inverted trapezoidal in turn. shape.

[0031] Such as figure 1 As shown, in this embodiment, the feed end of the ebullating fluidized bed body ("bed body" for short) is arranged at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com