A built-in diaphragm and quick release valve for quick release valve for automobile air pressure brake

A kind of air brake and diaphragm technology, applied in the direction of brakes, brake components, control valves and air release valves, etc., can solve the problems of occupying a lot of space, high cost, unable to reduce whistling, etc., and reduce the generation of high-frequency vibration. , the effect of reducing the concentration of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be described in detail by the following examples. The following examples are only exemplary, and can only be used to explain and illustrate the technical solutions of the present invention, but cannot be construed as limitations on the technical solutions of the present invention.

[0038] The upper surface described below in this application means that the surface facing the upper case is the upper surface, and the surface facing the lower case is the lower surface.

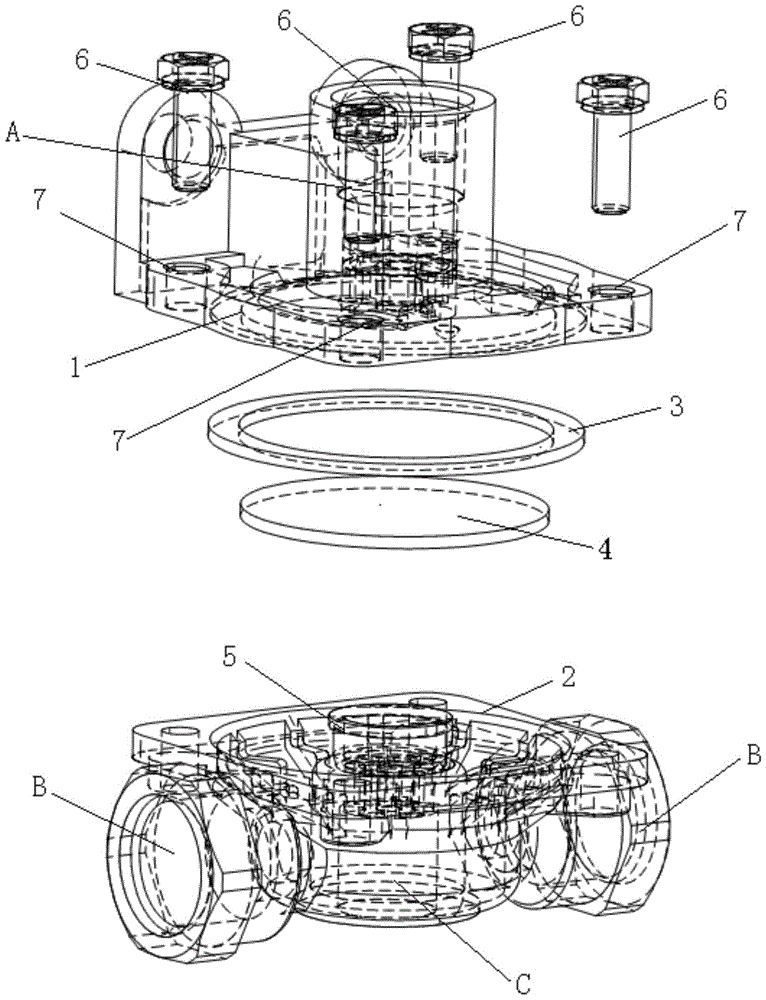

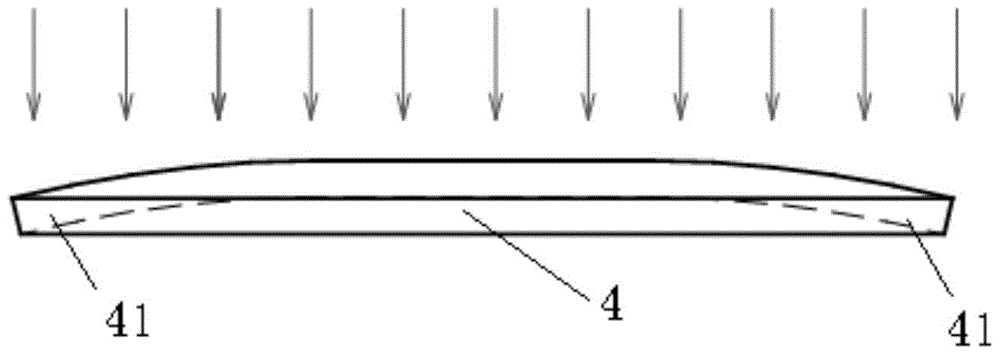

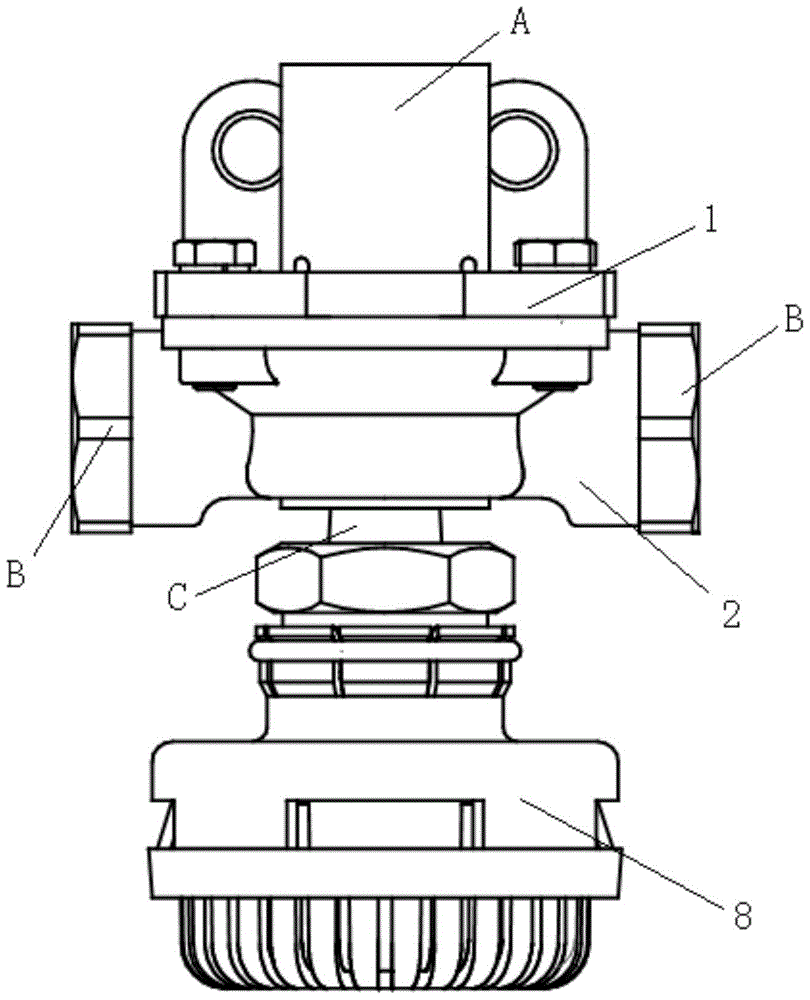

[0039] A quick release valve for automobile air brake, comprising a built-in diaphragm of the quick release valve, an upper casing, a lower casing, an air release valve, a sealing ring and a fastening bolt; The diaphragm of some quick-release valves is structurally improved, and the shock-absorbing device is omitted, and other structures of the quick-release valve are the same as those of the prior art.

[0040] The upper casing is provided with an air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com