Quick-release valve housing and quick-release valve for braking

A valve housing and housing technology, applied in the direction of control valve and air release valve, brake, brake components, etc., can solve the problems of occupying a lot of space and high cost of shock absorption equipment, and reduce exhaust whistle and impact. , The effect of suppressing high frequency vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

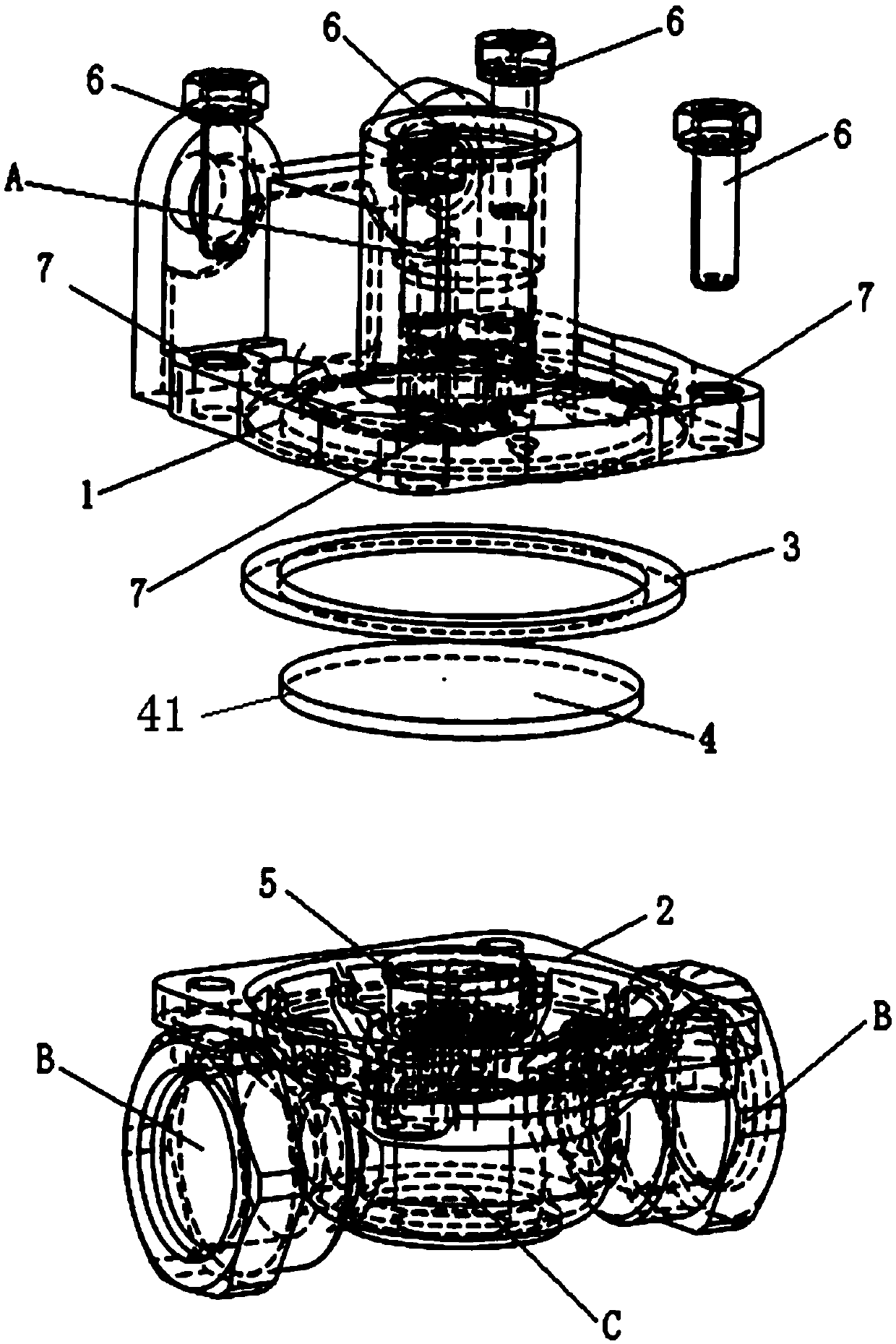

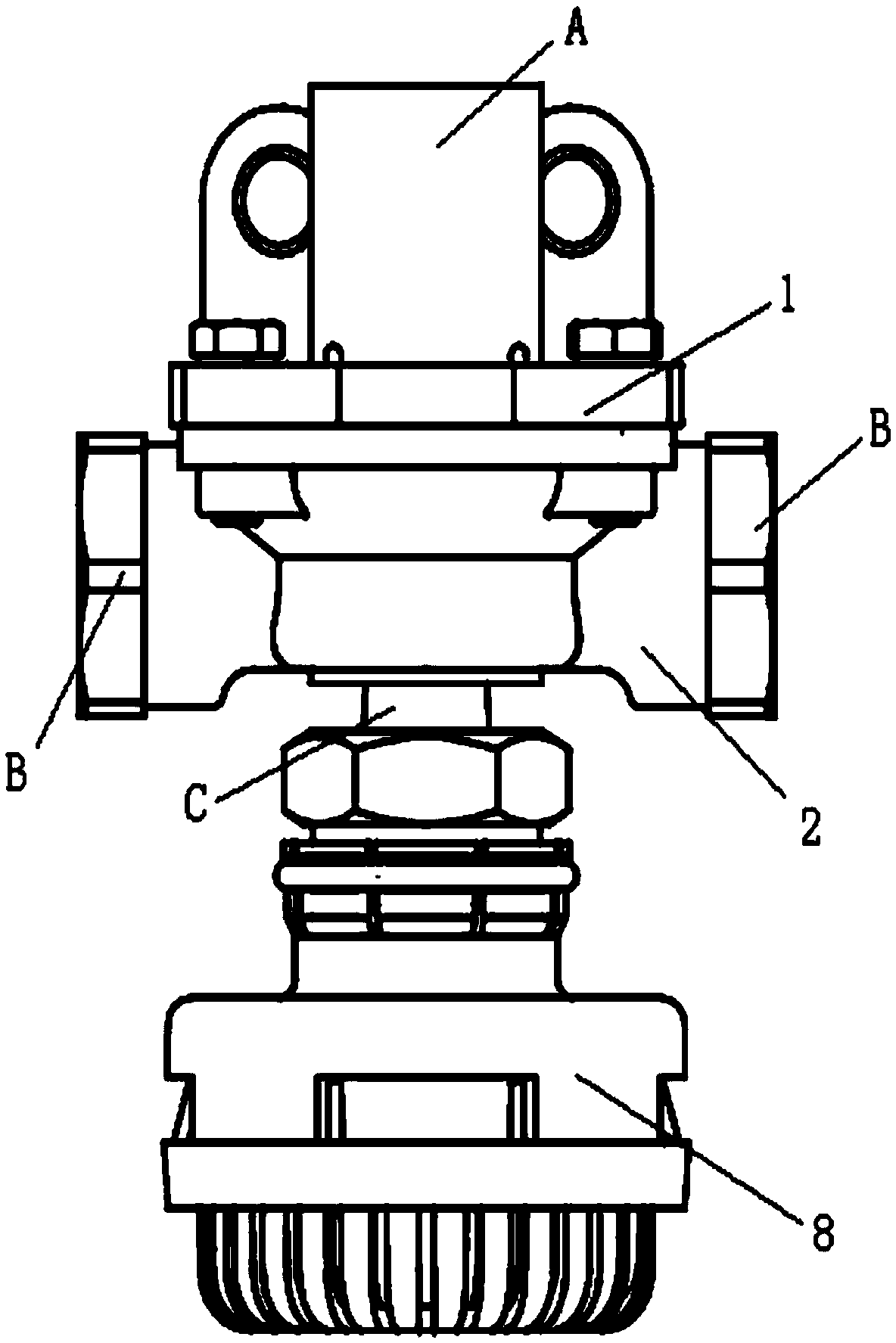

[0039] The application provides a quick release valve housing for braking, such as Figure 4 to Figure 7 As shown, it includes an upper case 200 and a lower case 500 , and the upper case 200 and the lower case 500 are fastened and connected by bolts 400 .

[0040] The upper casing 200 includes an upper casing body and an air inlet 201 arranged at the upper end of the upper casing, the air inlet 201 communicates with the inner cavity of the upper casing body; an air outlet is respectively arranged on both sides of the upper casing body 202. Each air outlet communicates with the inner cavity of the upper housing body; the upper housing body is provided with a mounting through hole for fixed connection with the lower housing through bolts.

[0041] The lower housing 500 includes a lower housing body and an exhaust valve 100, and the lower housing body and the exhaust valve are fixedly connected; in this application, the lower housing body and the exhaust valve are integrally form...

Embodiment 2

[0051] The present application provides a quick-release valve casing for braking, which includes an upper casing and a lower casing, and the upper casing and the lower casing are fastened and connected by bolts.

[0052] The upper casing includes an upper casing body and an air inlet arranged at the upper end of the upper casing, and the air inlet communicates with the inner cavity of the upper casing body; an air outlet is respectively arranged on both sides of the upper casing body, each The air outlets are all in communication with the inner cavity of the upper housing body; the upper housing body is provided with installation through holes for fixed connection with the lower housing through bolts.

[0053] The lower casing includes a lower casing body and an exhaust valve, and the lower casing body and the exhaust valve are fixedly connected; in this application, the lower casing body and the exhaust valve are integrally formed by casting.

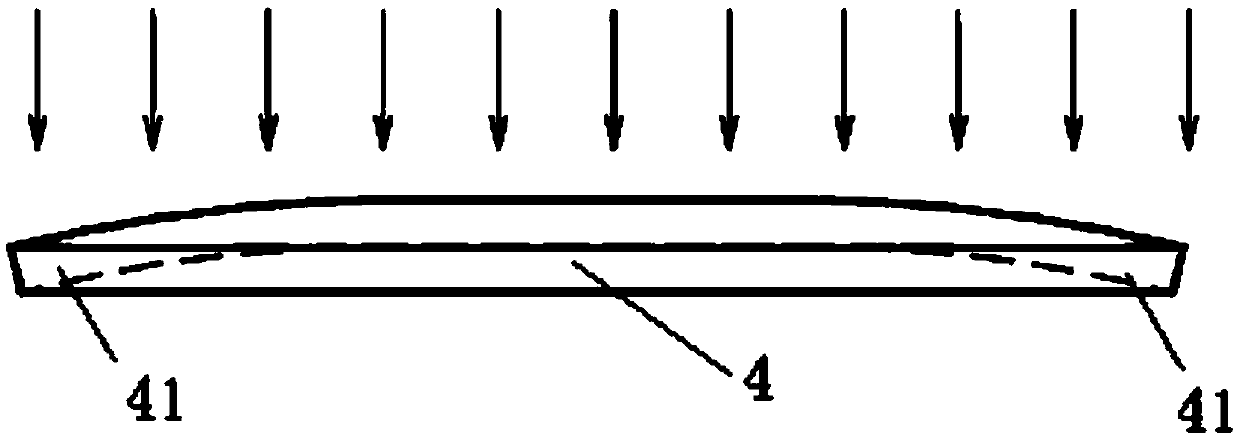

[0054] The exhaust valve is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com