Pin Shearing Device

A shearing device and pin technology, applied in the field of machining and manufacturing, can solve the problems of complicated operation, inconvenient use and high cost, and achieve the effects of convenient use, satisfying use requirements and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

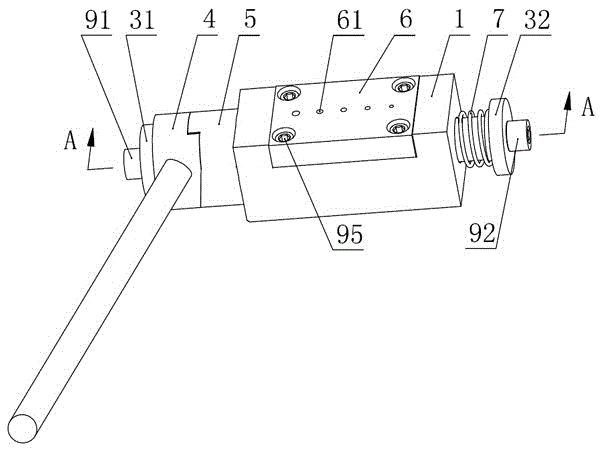

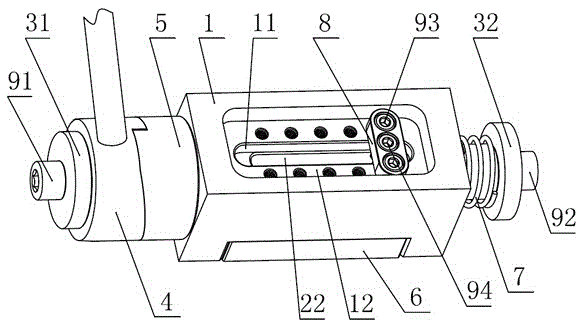

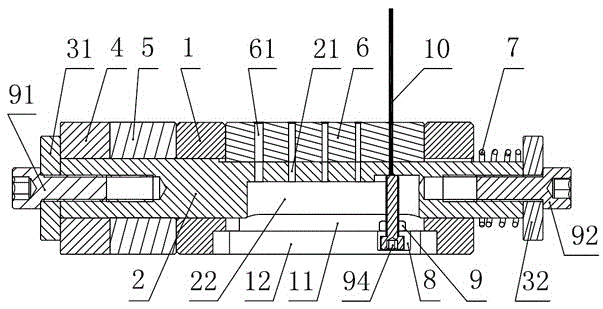

[0016] Such as figure 1 , figure 2 and image 3 As shown, the pin shearing device of the present invention includes a body 1 with a through hole through the front and back, and a through groove 11 vertically penetrating through the body 1 and the through hole is also opened on the body 1, and the moving rod 2 passes through the body 1 The body 1 extends out from the through hole on the top, and the first block 31 is locked on the front end of the moving rod 2 through the first locking bolt 91. A pressure rod 4 is movably sleeved on the moving rod 2, and the front end of the pressure rod 4 touches the front end of the moving rod 2. Leaning on the first stopper 31, a driving mechanism capable of driving the moving rod 2 to slide from back to front in the through hole is provided between the pressure rod 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com