Chute damping device for concrete pouring and mounting and using method thereof

A damping device and concrete technology, which is applied in the direction of construction, building structure, and building material processing, etc., can solve the problem that the inner wall corrugated damping effect is poor and cannot meet the requirements of concrete construction technical specifications, the length of the joint cannot meet the construction needs, the degree is small and the Issues such as no more than 2m

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

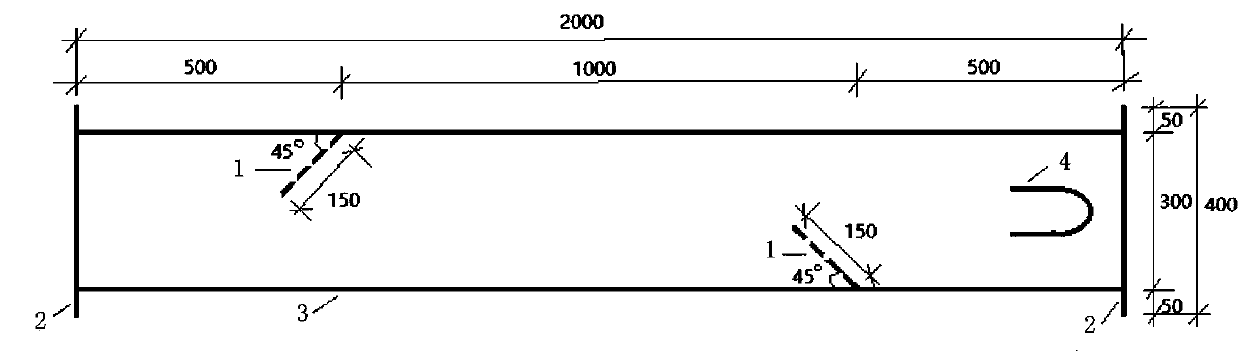

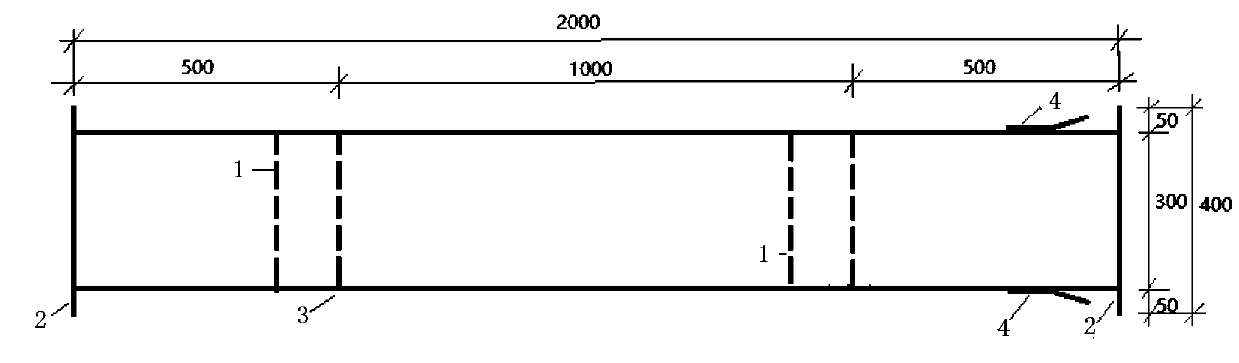

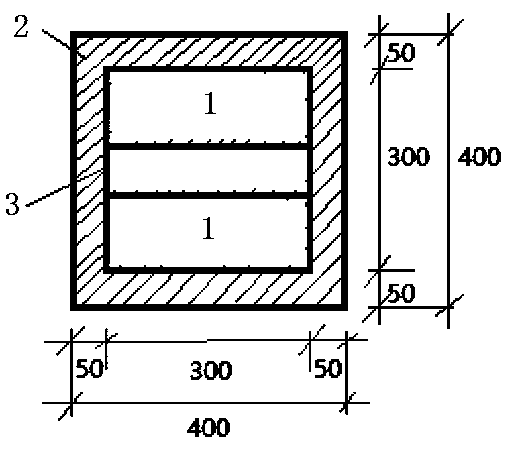

[0032] Such as Figure 1~3 As shown, a chute damping device for concrete pouring is composed of at least two identical chute dampers connected by flanges; the chute damper includes a chute cylinder 3, a flange 2, and a damping guide plate 1; the chute cylinder 3 is a cuboid welded by 4 identical rectangular steel plates with open ends; the rectangular steel plates constituting the chute damper are 2m in length, 294mm in width and 6mm in thickness; (294mm+6mm) square; the damping and guiding steel plate 1 is welded inside the chute cylinder 3, the damping and guiding steel plate 1 is a rectangular steel plate, the length of the short side of the damping and guiding steel plate 1 is 150mm, and the length of the long side is 294mm , with a thickness of 6 mm; the long side of the damping guide plate 1 is perpendicular to the central axis of the chute cylinder 3 (the line connecting the centers of the two open ends of the cuboid of the chute cylinder, not shown in the figure) and w...

Embodiment 2

[0037] This embodiment is the method for installing and using the chute damping device for pouring concrete in Embodiment 1.

[0038] Include the following steps:

[0039] 1) The truck crane is parked in place at the concrete pouring construction site;

[0040] 2) The first chute damper is hoisted in place;

[0041] 3) Use the vertical assembly method to install the second chute damper with bolt connection;

[0042] 4) Install other chute dampers in sequence according to the required lengths;

[0043] 5) Lift the installed chute damper to the concrete pouring site;

[0044] 6) A hose with an outer diameter of 150mm of the concrete pump truck is inserted into the chute damper for about 300mm, which can meet the pouring conditions and implement concrete pouring operations;

[0045] 7) After pouring concrete of different thicknesses, each chute damper shall be dismantled in turn by vertical dismantling;

[0046] 8) After each pouring operation, flush the pump pipe with a pump ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com