The multi-functional material-pushing mechanical arm device of the loader

A loader and multi-functional technology, which can be used in earth movers/shovels, mechanically driven excavators/dredgers, construction, etc., and can solve the problems that materials cannot be shoveled into buckets and materials are too heavy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

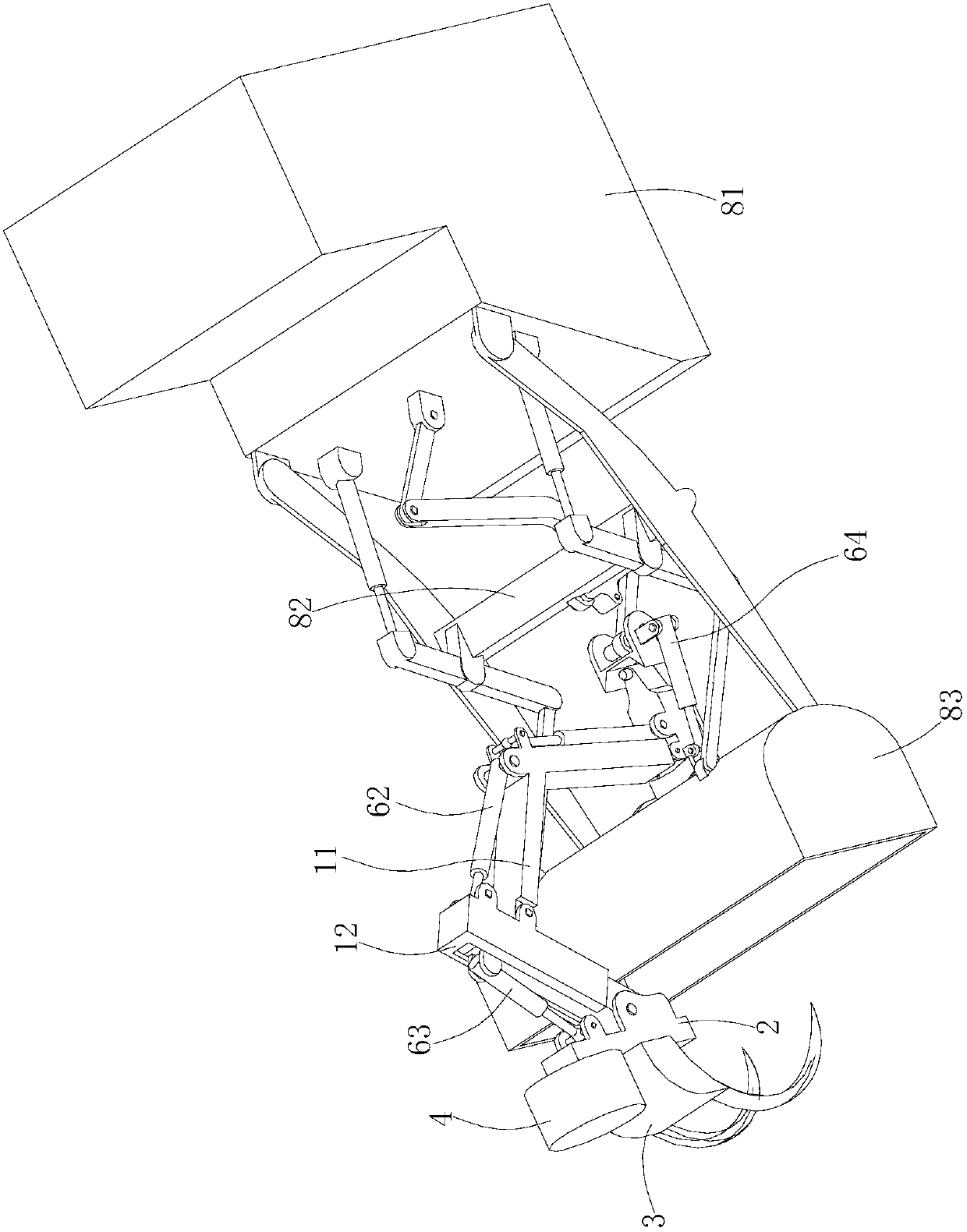

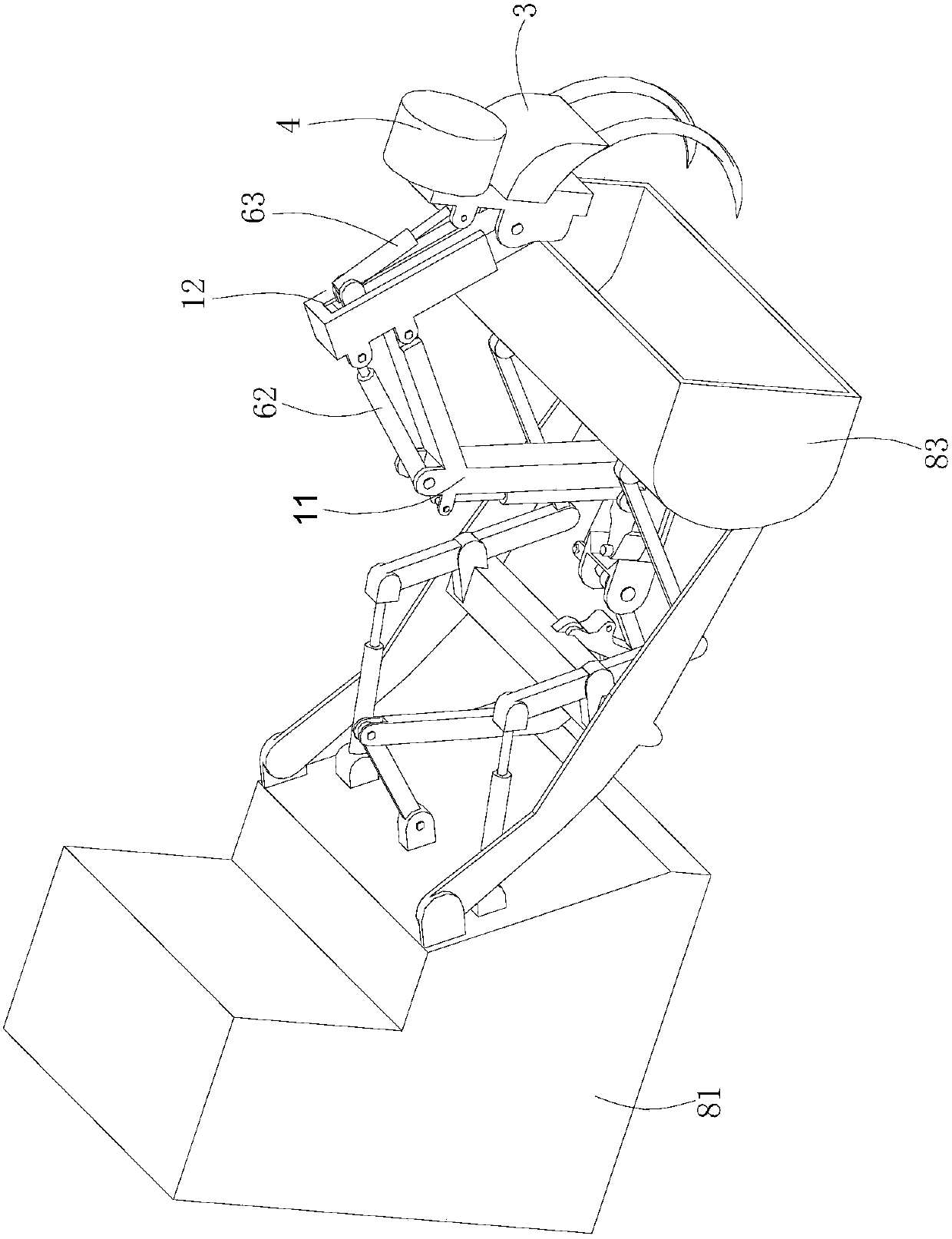

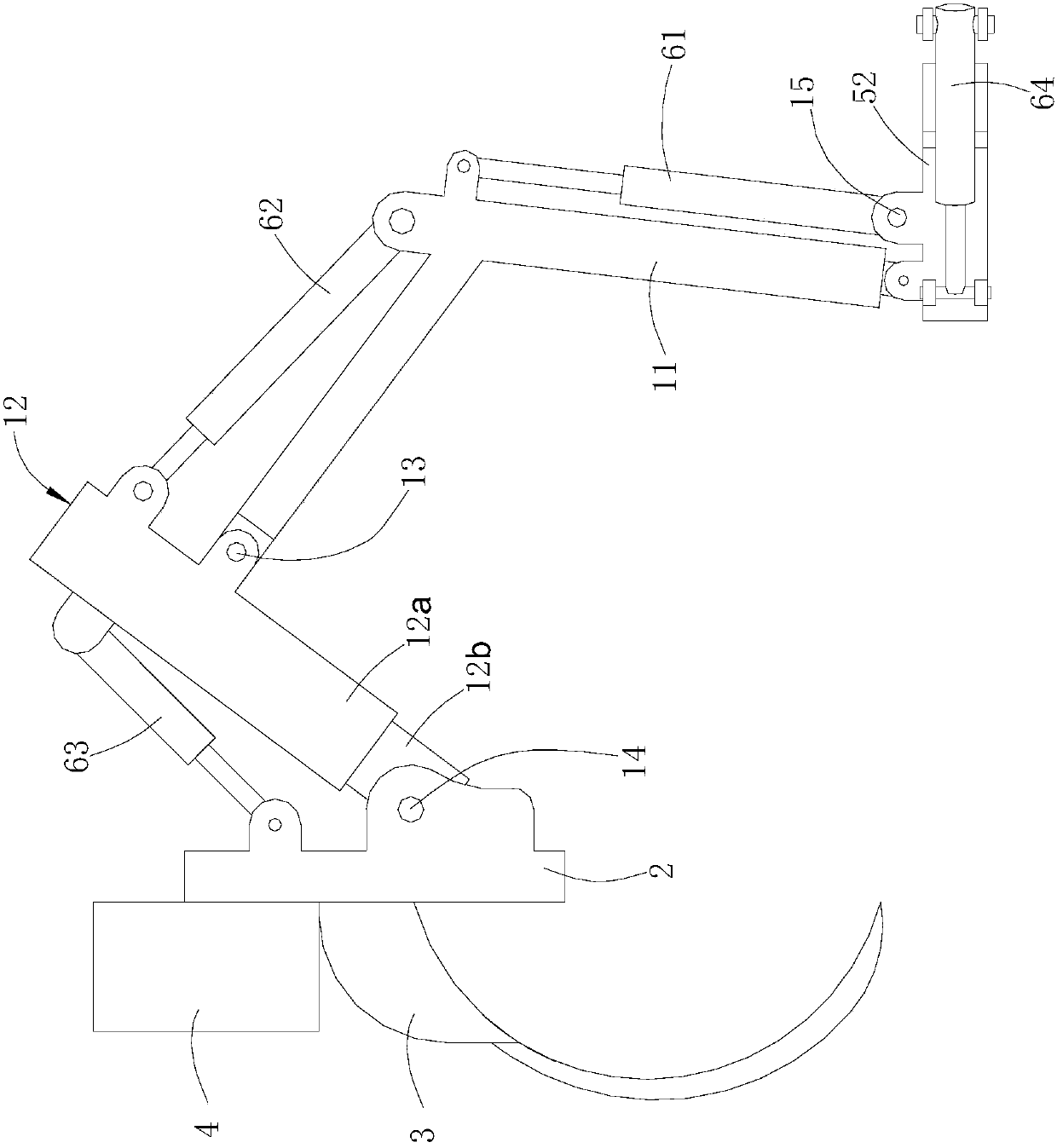

[0026] Such as Figures 1 to 8 as shown ( image 3 , Figure 4 The balance assembly and steering seat 51 are omitted, Figure 5 , 6 , 7 only show the bucket 83 of the loader, the vehicle frame and the steering seat 51 and the balance assembly of the mechanical arm device)

[0027] The mechanical arm device includes a mounting plate 2 , a material shifting arm assembly, an oil cylinder assembly, a steering assembly, a balance assembly, a material shifting claw 3 and an electromagnet 4 .

[0028] The shifting arm assembly includes a first shifting arm 11 and a second shifting arm 12, the middle part of the first shifting arm 11 has a bend, the second shifting arm 12 is a telescopic arm, and the second shifting arm 12 includes a cross-sectional shape It is a square first telescopic sleeve 12a and a second telescopic sleeve 12b, the second telescopic sleeve 12b is set in the first telescopic sleeve 12a and the left end of the second telescopic sleeve 12b extends out of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com