Fan capable of realizing rotor counterweight balance and counterweight balancing method thereof

A counterweight balance and rotor technology, applied in the field of machinery, can solve problems such as failure to work, vibration, etc., to achieve the effect of ensuring the balance of counterweight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

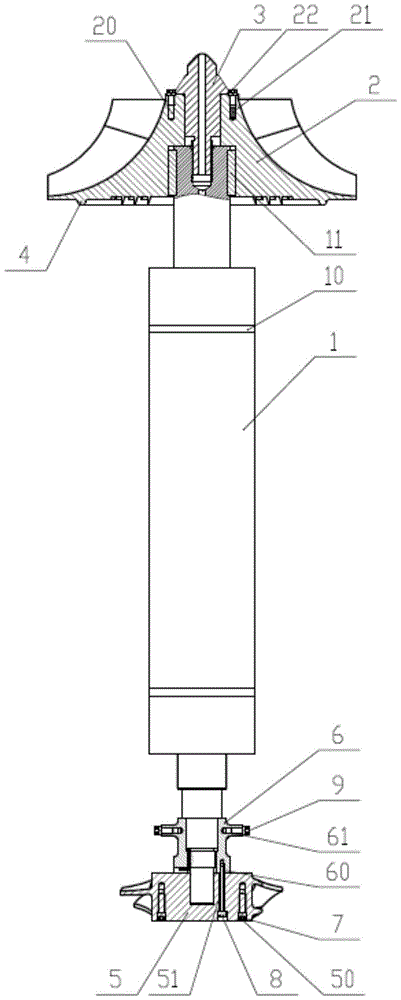

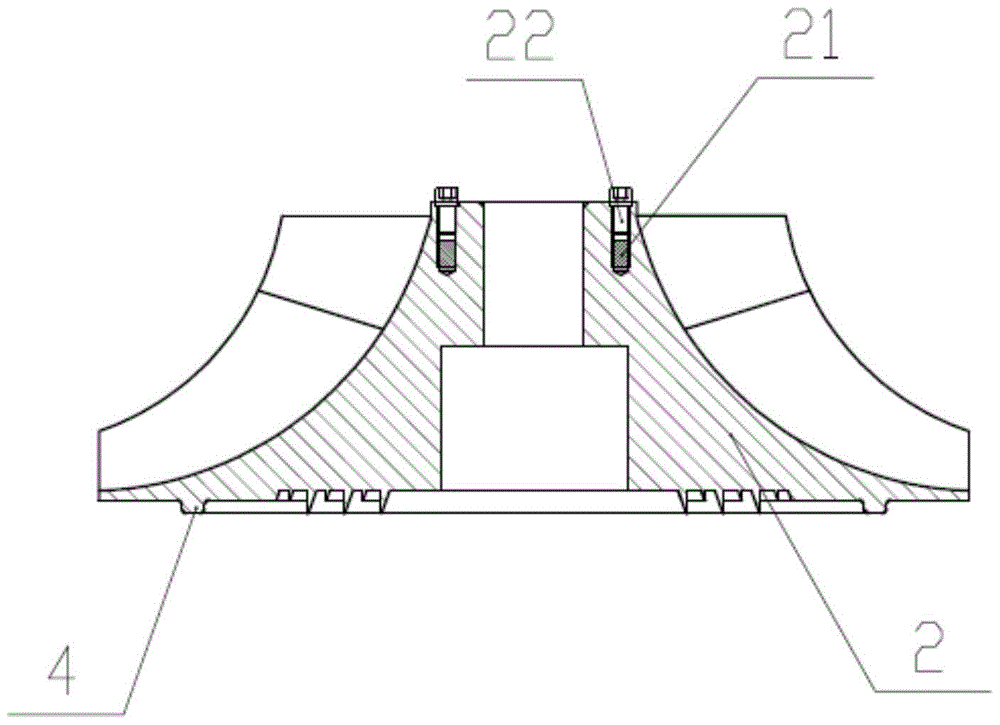

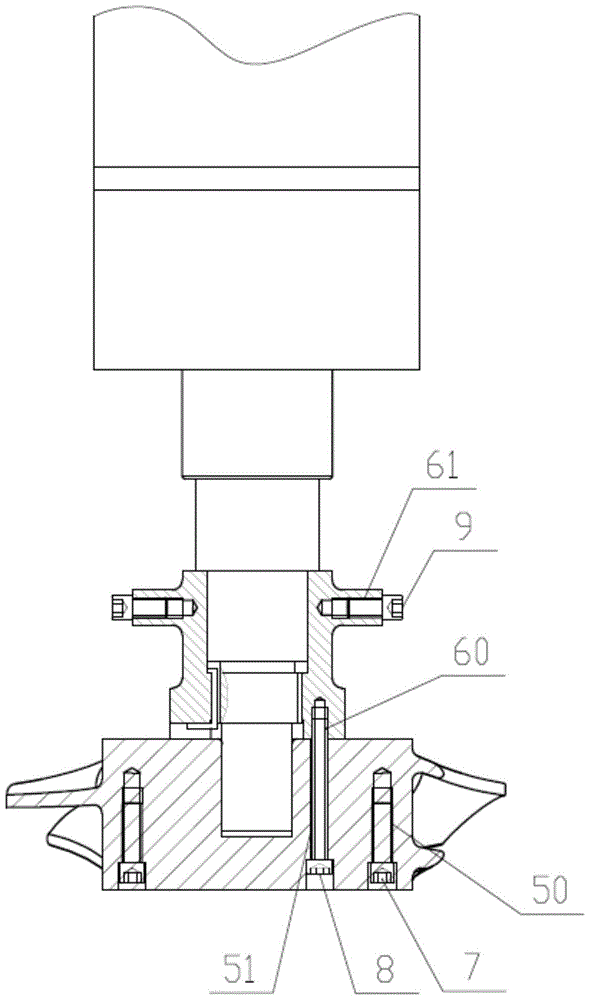

[0023] Please refer to figure 1 As shown, the fan of the present invention includes a rotor 1; an impeller 2 mounted on the rotor 1; and a flow guide cone 3. The central shaft hole of the impeller 2 is matched with the rotor 1, the central shaft hole of the impeller 2 is aligned with the rotor shaft, the impeller 2 is installed in the direction of the rotor 1, and then the impeller 2 is installed and fixed on the rotor 1 through the key 11. The upper end surface of the impeller 2 is recessed at equal intervals along the same circumferential direction with a plurality of first weight screw holes 20, and the first weight screw 21 and / or the second weight screw holes 20 are installed in the first weight screw holes 20 Weight screw 22, where the first weight screw 21 and the second weight screw 22 can be located in different first weight screw holes 20 respectively, or there may be a first weight screw 21 and a second weight screw 22 is installed in one weight screw hole 20 at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com