Adjustment-type plastic granule storage device

A technology for plastic granules and storage devices, applied in packaging, large containers, transportation and packaging, etc., can solve the problem of inability to adjust the direction of discharge, and achieve the effect of improving efficiency and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

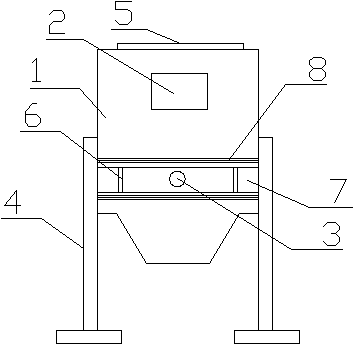

[0011] Such as figure 1 It is a structural schematic diagram of the present invention, an adjustable plastic particle storage device, including a storage body 1, an inspection door 2, a discharge port 3, a bracket 4 and a feed port 5, and the side end of the storage body 1 is provided with an inspection door 2 and a discharge port 3. The storage body 1 is connected to the bracket 4, the top of the storage body 1 is provided with a feed port 5, the upper end of the storage body 1 is provided with a feed port 5, the upper and lower ends of the storage body 1 are fixedly connected, and the upper and lower ends of the storage body 1 are connected There is a discharge ring 7 connected to the external rotation, the discharge ring 7 is provided with a discharge port 3, the upper and lower ends of the storage body 1 are fixedly connected by the support column 6, and the upper and lower ends of the storage body 1 are provided with chute 8, The snap ring on the inner wall of the dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com