Pile fabric opening and pressing device

A flannelette and loosening technology, which is applied in the field of ironing devices for fluffy ironing, can solve the problems of unable to iron fluffy fabrics, etc., and achieve the effect of good ironing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

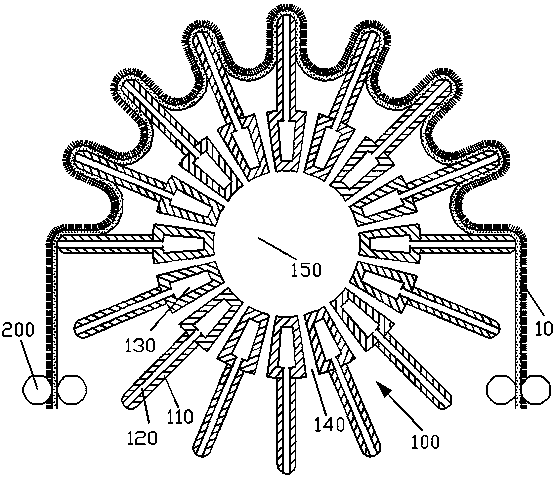

[0014] refer to figure 1 , in this embodiment, the flannelette opening and ironing device includes a roller 100 driven to rotate by a driver, and a support piece 110 arranged in a radial direction is arranged around the body of the roller 100, and the top of the support piece 110 is in the shape of Arc-shaped and evenly distributed with steam outlets, the inside of the support sheet 110 is provided with a steam channel 120 for supplying steam to the steam outlet, and the steam channel 120 communicates with a steam supply chamber 130 arranged in the roller, so The cylinder body of the roller 100 is also surrounded by air pumping slots 140, the air pumping slots 140 communicate with the air pumping channels 150 arranged in the roller 100, and the two sides of the roller 100 are respectively provided with direction The roller 100 conveys in and out of a pair of guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com