Boiler assembly and steam ironing equipment applying same

A technology for ironing equipment and boilers, applied in applications, hand irons, household appliances, etc., can solve problems such as boiler heating function failure, boiler and heating element cracks, boiler swelling and deformation, etc., to achieve fast ironing speed and ironing Good effect, avoid the effect of bulging and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

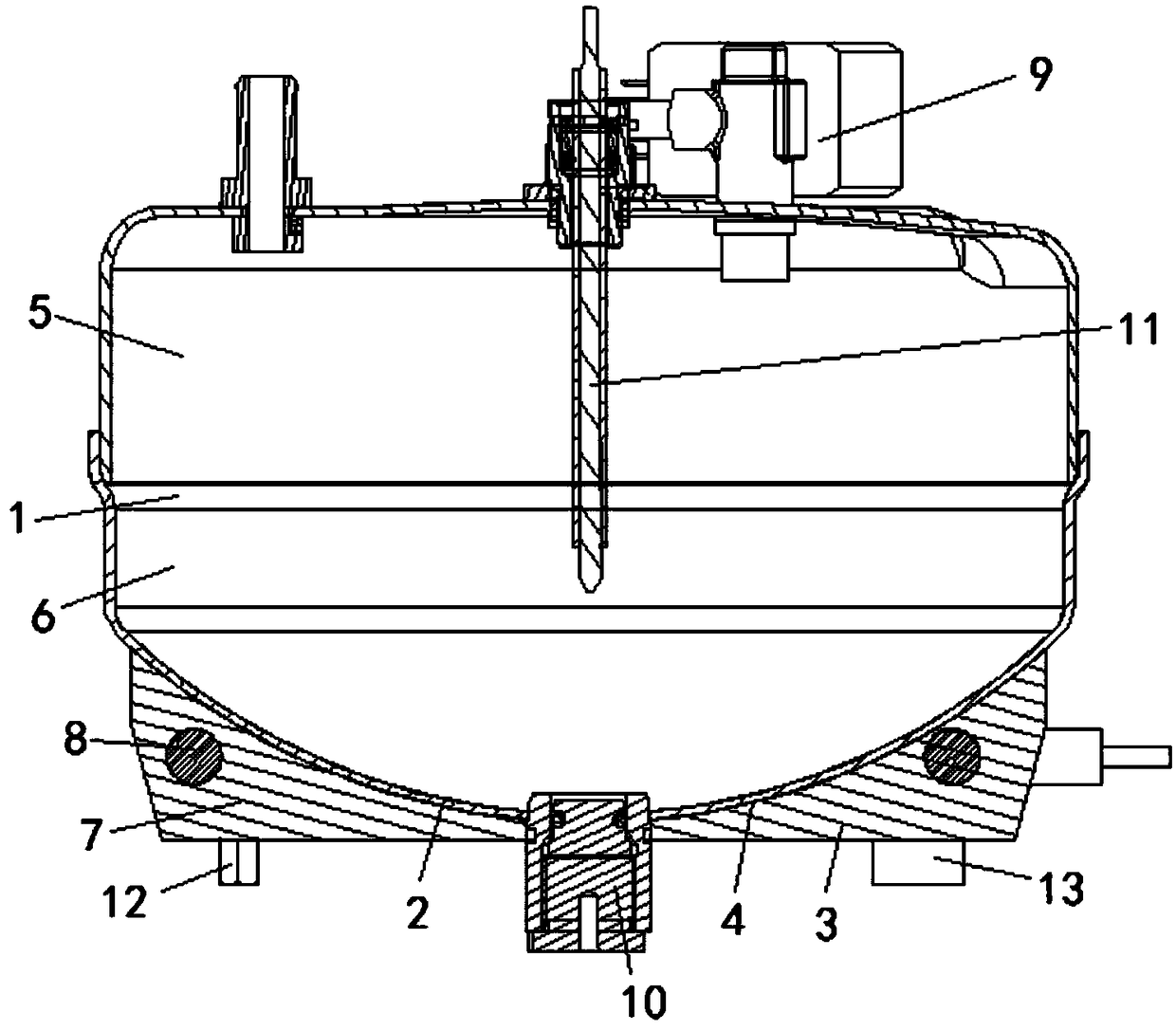

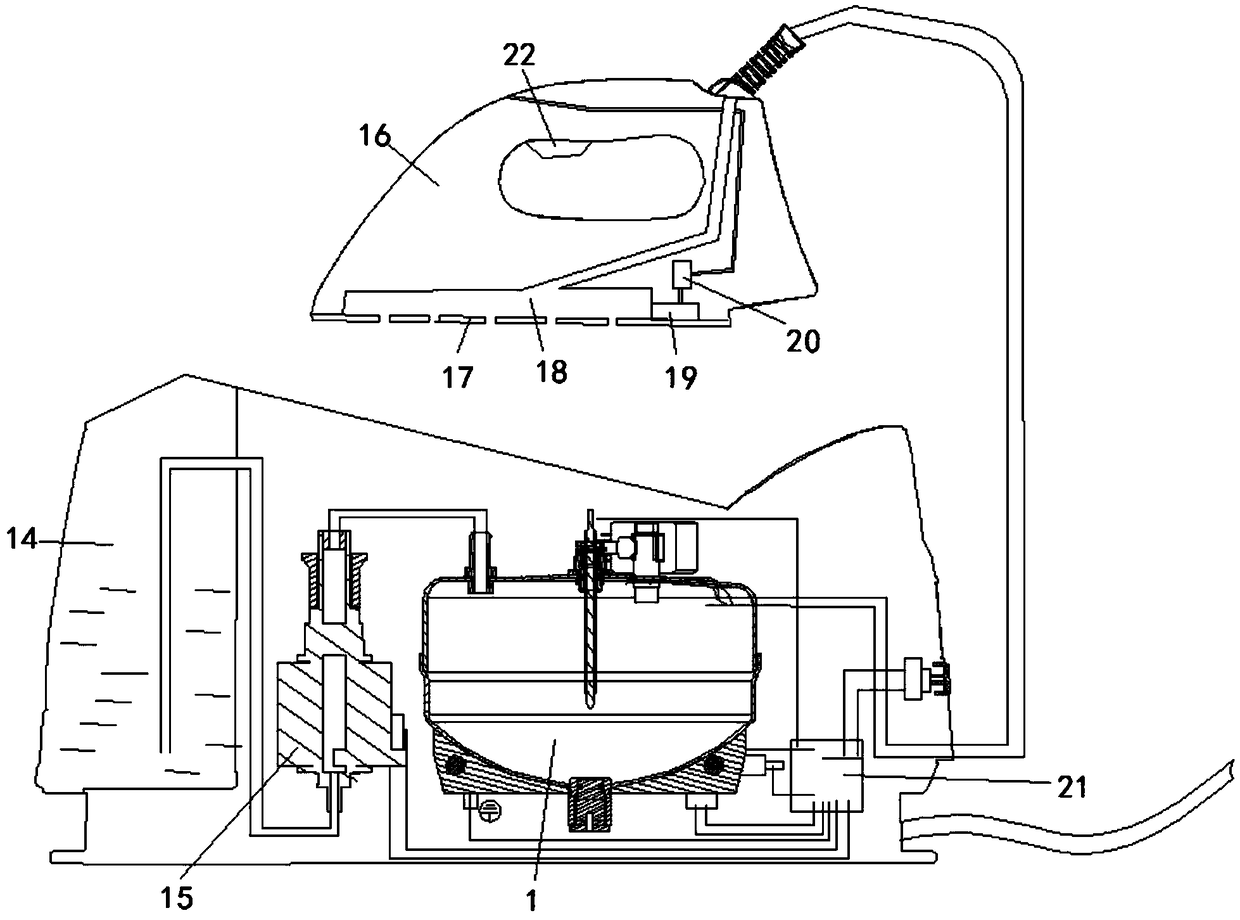

[0020] like figure 1 As shown, a boiler assembly according to the present invention includes a boiler body 1 and a heating plate 3. It is characterized in that the lower end surface of the boiler body 1 is a convex arc surface 2, and the upper end surface of the heating plate 3 is The inner concave arc surface 4, the lower end surface of the boiler body 1 and the upper end surface of the heating plate 3 are fixedly connected through the aforementioned mutually matching arc surfaces. In the boiler assembly of the present invention, the boiler body 1 and the heating plate 3 are connected by matching arc surfaces. Due to the special shape of the arc surfaces, the pressure required at the bottom of the boiler is smaller under the same pressure, so that even if the boiler The internal steam pressure is increased to a higher level, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com