Large Displacement Output Magnetostrictive Actuator

A technology of magnetostriction and magnetostriction rods, which is applied in the direction of piezoelectric effect/electrostriction or magnetostriction motors, generators/motors, electrical components, etc., to achieve high electromechanical conversion rate, high response speed, high The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

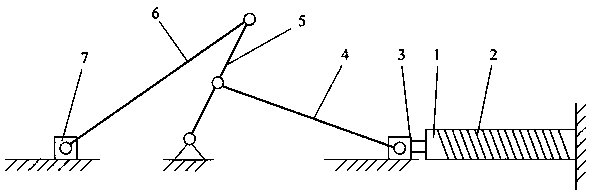

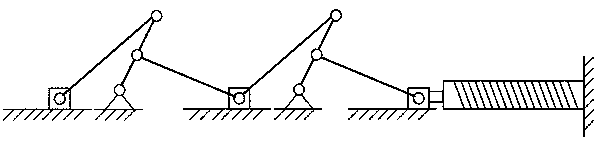

[0017] The following will be combined with figure 1 with one A specific embodiment further illustrates the large displacement output magnetostrictive driver of the present invention;

[0018] Such as figure 1 It is shown that the large displacement output magnetostrictive driver of the present invention mainly consists of a magnetostrictive rod 1 that can expand and contract in the length direction, a drive coil 2 wound on the magnetostrictive rod, and a first slide block 3, a first connecting rod Composed of a double crank connecting rod displacement amplification mechanism composed of rod 4, crank 5, second connecting rod 6 and second slider 7;

[0019] Wherein the right end of the magnetostrictive rod 1 is a fixed end, and the left end is a free end, the first slide block 3 is connected with the free end of the magnetostrictive rod 1, and the first slide block 3 can be moved along the longitudinal direction of the magnetostrictive rod 1 degrees of freedom to slide. One...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com