Printing area control method and printing method of double-printing-head 3D printer

A technology of 3D printer and printing area, applied in the field of 3D printing, can solve the problem of limited improvement of printing efficiency, and achieve the effect of improving printing efficiency and preventing conflicts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the accompanying drawings and specific examples.

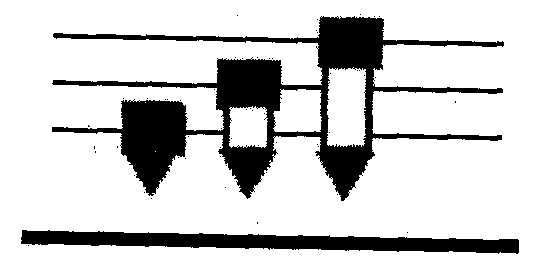

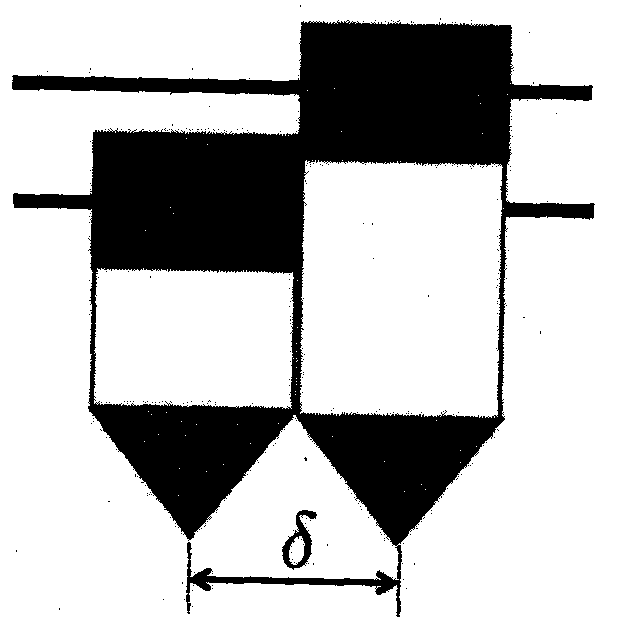

[0025] The motion locus of the print head of the 3D printer in the prior art is a plane, so if you want to set up multiple independent print heads, you must make the motion locus planes of these print heads non-overlapping, for example, figure 1 Shown is a 3D printer with 3 print heads. And the far ends of these print heads must be on a plane, so that a print surface of the workpiece (that is, a cross section of the workpiece) can be printed simultaneously by multiple print heads. The principle of the 3D printer using two print heads is the same, and there will also be a problem of conflict between the print heads during the work process.

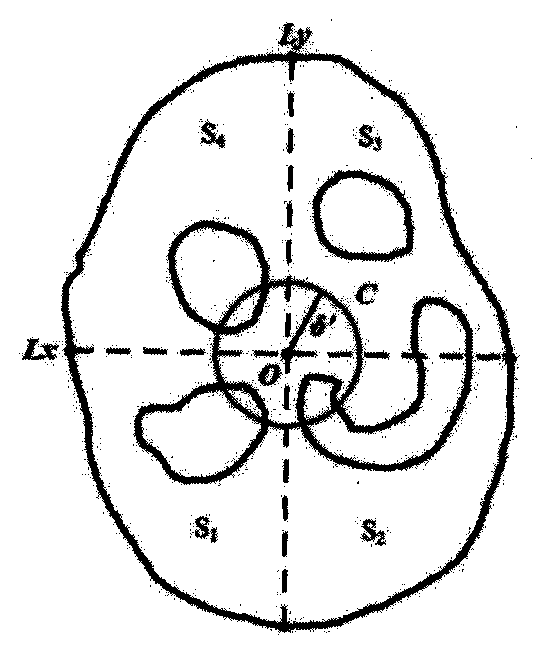

[0026] Therefore, the embodiment of the present invention divides the printing area into several conflic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com