Pencil sharpener used for pen

A pencil sharpener and drawing pen technology, applied in the field of pencil sharpeners, can solve the problems of sharpening residue pollution and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

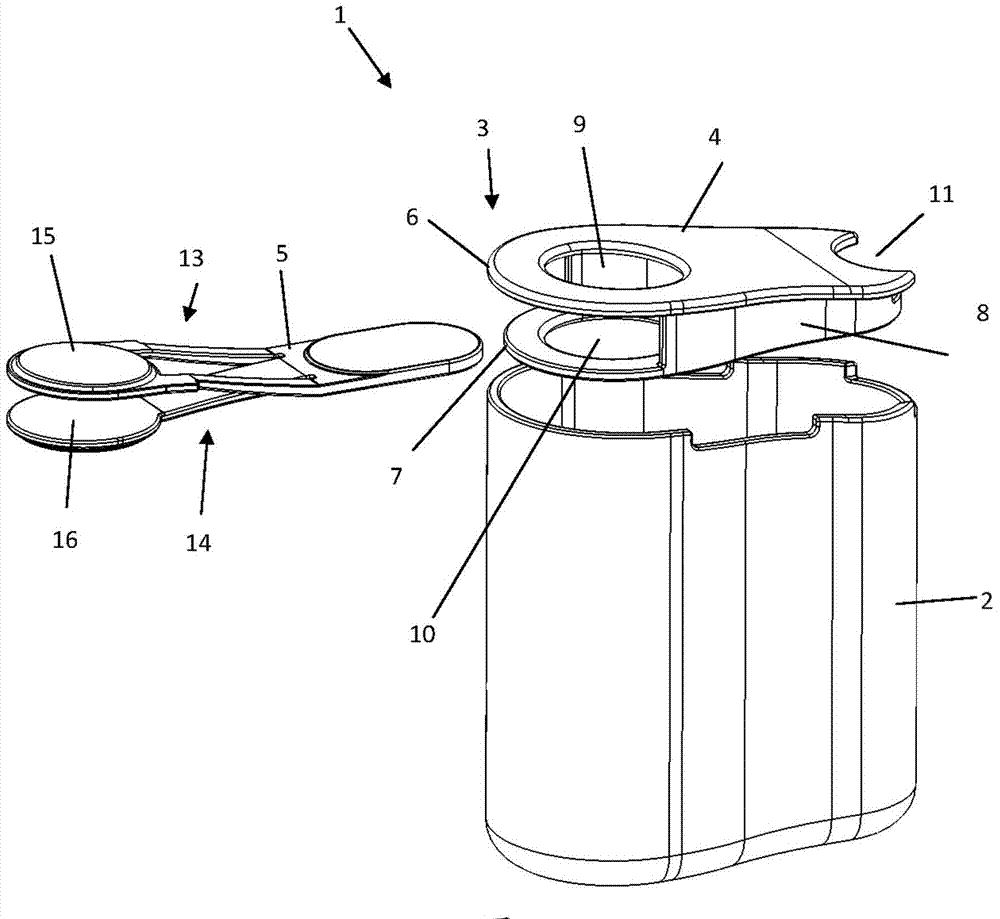

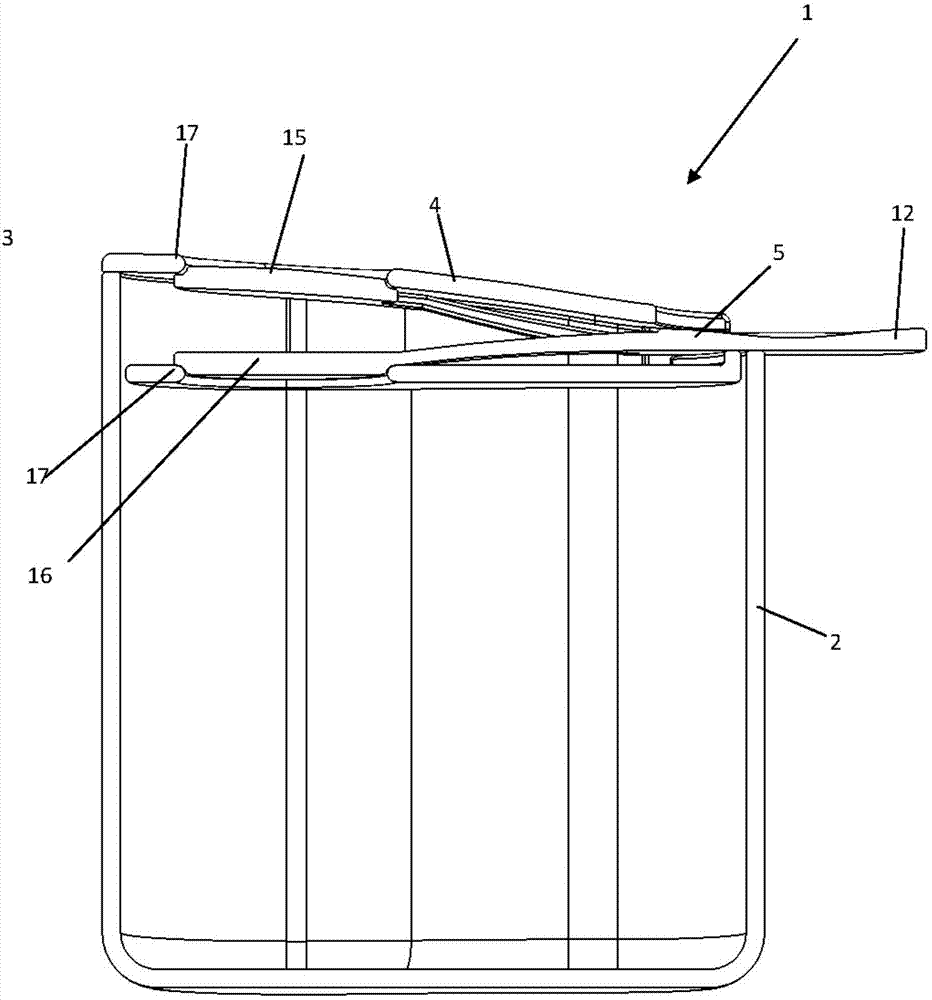

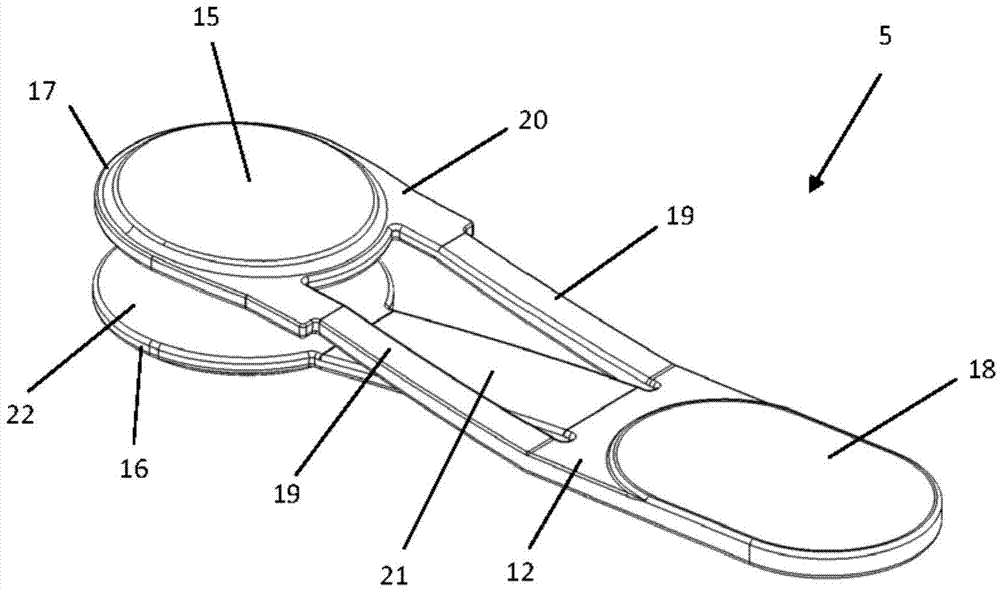

[0084] figure 1 Shows Sharpener 1, however in figure 1 The actual sharpener element is not shown, so figure 1 Restricted only to the housing and the closure, the pencil sharpener comprises a housing 2 and a closure 3 consisting of a first closure element 4 and a second closure element 5 .

[0085] In this embodiment, the first closure element 4 has two planar sections 6 and 7 which are rigidly connected to one another by a side wall 8 which is interrupted at two points. Rigidity in this case means that the planar sections 6 and 7 cannot move away from each other due to the insertion of the second closure element 5 , nor can the spacing change due to the first closure part 4 being pushed into the housing 2 . Nevertheless, the first closure element 4 can still be made of an at least somewhat elastic material, for example plastic.

[0086] The first closure element 4 has two openings 9 and 10 so that a pen can be guided through the first closure element 4 . Furthermore, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com