Process system for treating toxic and harmful tail gas by dry chemical filtering device

A technology of chemical filtration and process system, which is applied in the field of process system of dry chemical filtration device to treat toxic and harmful tail gas, which can solve the problems of safety accidents, exhaust gas not being purified, waste of adsorbent, etc., so as to avoid escape and facilitate Operation management, realizing the effect of online replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

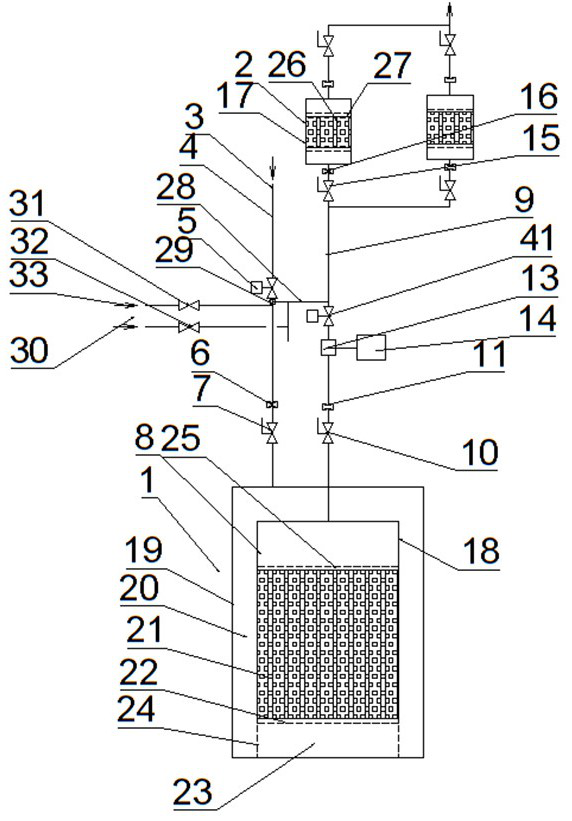

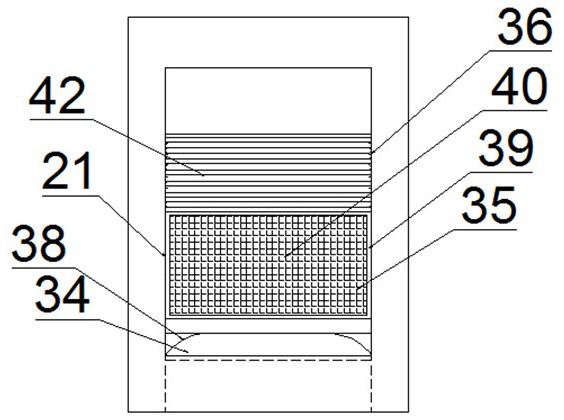

[0031]Such asfigure 1 A dry chemical filtration device treats a process system of toxic and harmful exhaust gas, including the main adsorption system 1 and auxiliary adsorption system 2, the main adsorption system 1 sequentially passes the process exhaust gas through the inlet 3, the inlet line 4, and automatically control the valve 5. The quick connector 6, the manual cut valve 7 and the main sucking barrel 8 are filtered, the automatic control valve 5 fixed to the quick joint 6 side, the quick joint 6 and the manual shut-off valve 7 On the side fixed connection, the manual shut-off valve 7 is connected to the main adsorption barrel 8 inlet, and the process exhaust gas is filtered through the main adsorption barrel 8, and the outlet end of the main adsorption barrel is entered into the outlet pipeline 9. A third manual shutter valve 10, a rapid connection clamp 11, a concentration detecting port 12, and a third automatic shutoff valve 41 are sequentially connected, and a concentrat...

Embodiment 2

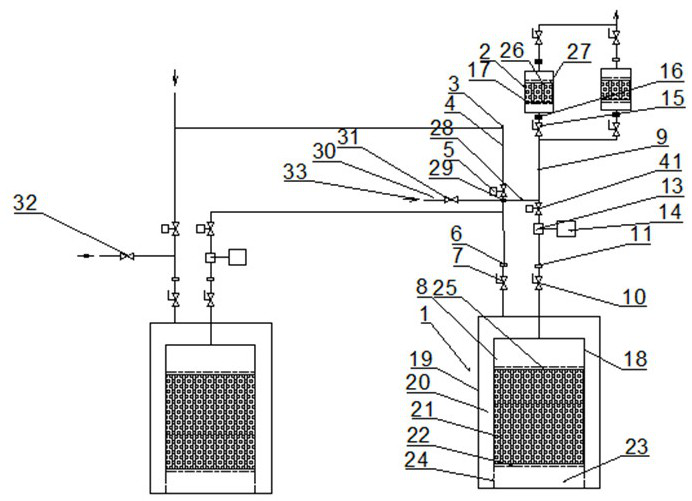

[0046]A dry chemical filtration device treats a process system of toxic and harmful exhaust, including the main adsorption system 1 and auxiliary adsorption system 2, the main adsorption system 1 sequentially passes the process exhaust gas through the inlet 3, the inlet line 4, automatically control the valve 5, fast The connector 6, the manual cutout valve 7 and the main sucking barrel 8 are filtered, the automatic control valve 5 is fixed to the quick joint 6 side, the flash joint 6 and the manual shutoff valve 7 side fixed Connecting, the manual cutting valve 7 is connected to the main adsorption barrel 8 inlet, and the process exhaust gas is filtered through the main adsorption barrel 8, and the outlet end of the main adsorption barrel 8 enters the outlet pipeline 9, the The third manual shut-off valve 10, the rapid connection clamp 11, the concentration detecting port 12, and the third automatic cutting valve 41 are connected, and the concentration detecting port 12 is connecte...

Embodiment 3

[0061]A dry chemical filtration device treats a process system of toxic and harmful exhaust, including the main adsorption system 1 and auxiliary adsorption system 2, the main adsorption system 1 sequentially passes the process exhaust gas through the inlet 3, the inlet line 4, automatically control the valve 5, fast The connector 6, the manual cutout valve 7 and the main sucking barrel 8 are filtered, the automatic control valve 5 is fixed to the quick joint 6 side, the flash joint 6 and the manual shutoff valve 7 side fixed Connecting, the manual cutting valve 7 is connected to the main adsorption barrel 8 inlet, and the process exhaust gas is filtered through the main adsorption barrel 8, and the outlet end of the main adsorption barrel 8 enters the outlet pipeline 9, the The third manual shut-off valve 10, the rapid connection clamp 11, the concentration detecting port 12, and the third automatic cutting valve 41 are connected, and the concentration detecting port 12 is connecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com