Method for solidifying radioactive spent scintillation liquid

A technology of radioactive waste and scintillation fluid, applied in the field of waste treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

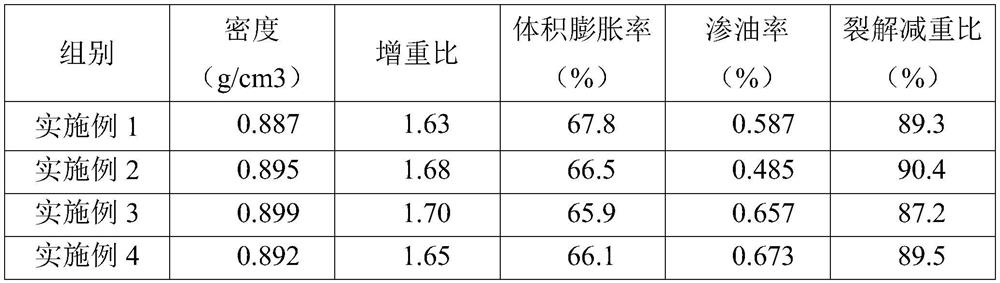

Examples

Embodiment 1

[0022] A method for curing radioactive waste scintillation fluid, specifically comprising the following steps:

[0023] Step 1: Take 20.0ml of radioactive waste scintillation fluid produced by a factory sample analysis, add 4.0g of starch, 2.0g of cellulose, 2.0g of stearic acid and 2.0g of activated carbon to the radioactive waste scintillation fluid, stir well to obtain mixture I.

[0024] Step 2: Heat the mixture I obtained in step 1 in a water bath at 70.0°C until the stearic acid in the mixture I is dissolved to obtain the mixture II.

[0025] Step 3: Add 2.0 mL of NaOH solution with a molar concentration of 5 mol / L to the mixture II obtained in Step 2 at 70.0° C., and stir for 2-3 minutes to react. After cooling, a solidified body of radioactive waste scintillation fluid is obtained.

[0026] The radioactive scintillation fluid was solidified by the method of this example, and the cured body was loose, non-adhesive, free of free liquid, and non-stick to the wall.

[002...

Embodiment 2

[0029] A method for curing radioactive waste scintillation fluid, specifically comprising the following steps:

[0030] Step 1: Take 20.0ml of radioactive waste scintillation fluid produced by a factory sample analysis, add 8.0g of starch, 6.0g of cellulose, 4.0g of stearic acid and 2.0g of activated carbon to the radioactive waste scintillation fluid, stir well to obtain mixture I.

[0031] Step 2: Heat the mixture I obtained in the step 1 in a water bath at 80.0°C until the stearic acid in the mixture I is dissolved to obtain the mixture II.

[0032] Step 3: Add 4.0 mL of NaOH solution with a molar concentration of 8 mol / L to the mixture II obtained in Step 2 at 80.0° C., and stir for 2-3 minutes to react. After cooling, a solidified body of radioactive waste scintillation fluid is obtained.

[0033] The radioactive scintillation fluid was solidified by the method of this example, and the cured body was loose, non-adhesive, free of free liquid, and non-stick to the wall.

...

Embodiment 3

[0036] A method for curing radioactive waste scintillation fluid, specifically comprising the following steps:

[0037] Step 1: Take 20.0ml of radioactive waste scintillation fluid produced by a factory sample analysis, add 8.0g of starch, 6.0g of cellulose, 4.0g of stearic acid and 4.0g of activated carbon to the radioactive waste scintillation fluid, stir well to obtain mixture I.

[0038] Step 2: Heat the mixture I obtained in the step 1 in a water bath at 80.0°C until the stearic acid in the mixture I is dissolved to obtain the mixture II.

[0039] Step 3: Add 4.0 mL of NaOH solution with a molar concentration of 8 mol / L to the mixture II obtained in Step 2 at 80.0° C., and stir for 2-3 minutes to react. After cooling, a solidified body of radioactive waste scintillation fluid is obtained.

[0040] The radioactive scintillation fluid was solidified by the method of this example, and the cured body was loose, non-adhesive, free of free liquid, and non-stick to the wall.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molar concentration | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com