Precision measurement method for one-dimensional displacement

A precision measurement and displacement technology, applied in measurement devices, devices using electrical/magnetic methods, instruments, etc., can solve the problems of high cost, sensitivity to environmental pollution, measurement error and drift, etc., and achieves low installation accuracy requirements, measurement High precision and flexible solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

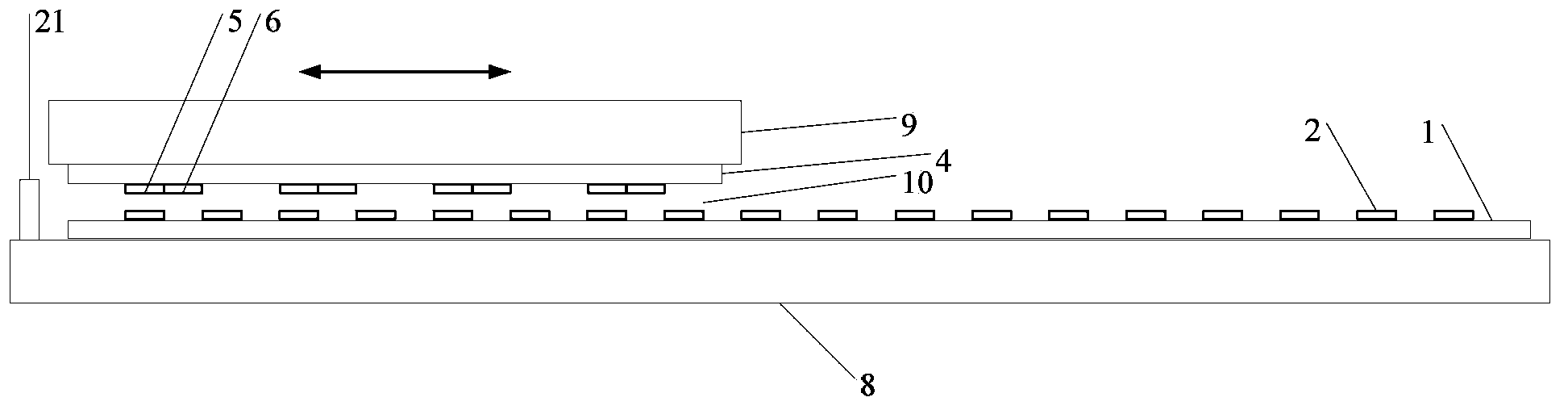

[0017] Such as figure 1 As shown, a one-dimensional displacement precision measurement method is characterized in that:

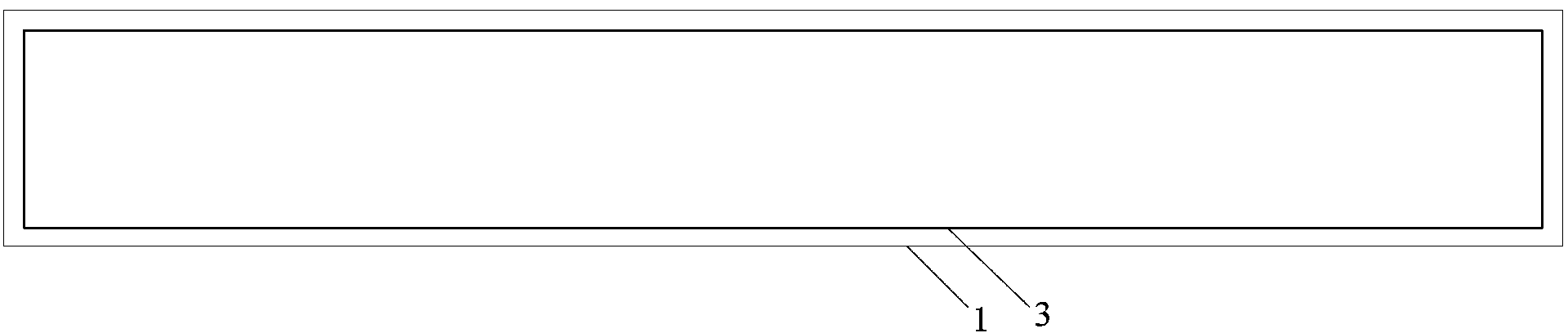

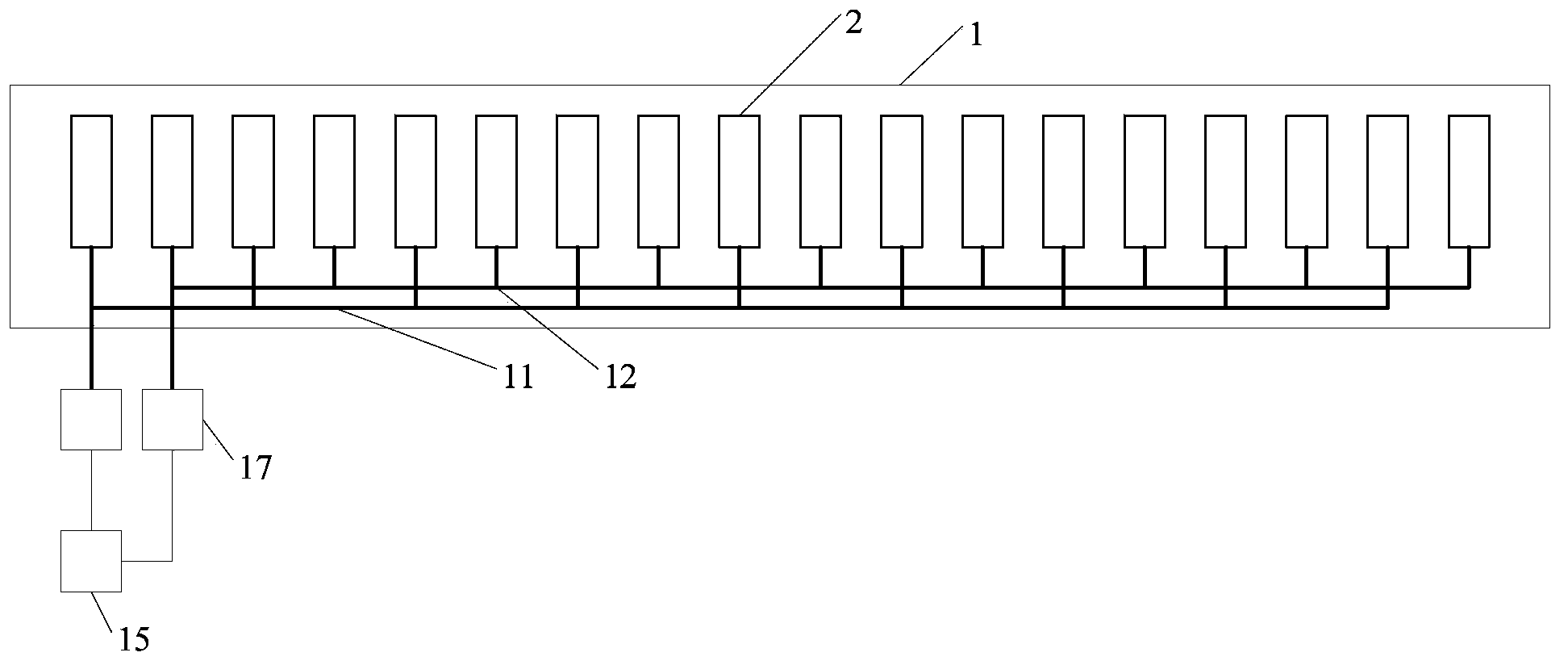

[0018] A. Prepare the emitter electrode 2 on the upper surface of the emitter electrode insulating substrate 1. The width of the emitter electrode 2 is the same as the spacing. The total cumulative width of the emitter electrode 2 and the spacing is greater than the one-dimensional displacement stroke to be measured. The lower surface of the emitter electrode insulating substrate 1 is covered with shield electrode 3 (as figure 2 , 3 shown);

[0019] B. Prepare multiple sets of receiving electrode one 5 and receiving electrode two 6 on the lower surface of the receiving electrode insulating substrate 4, the width of the receiving electrode one 5 and the receiving electrode two 6 is consistent with that of the transmitting electrode 2, the receiving electrode one 5 and the receiving electrode two 6 Closely adjacent and kept insulated from each other, the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap