Method and device for datum determination and plausibility check of actuator reference position

A technology of reference position, actuator, applied in the direction of measuring device, mechanical device, mechanical measuring device, etc., can solve the problems of difference, brake wear, readjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

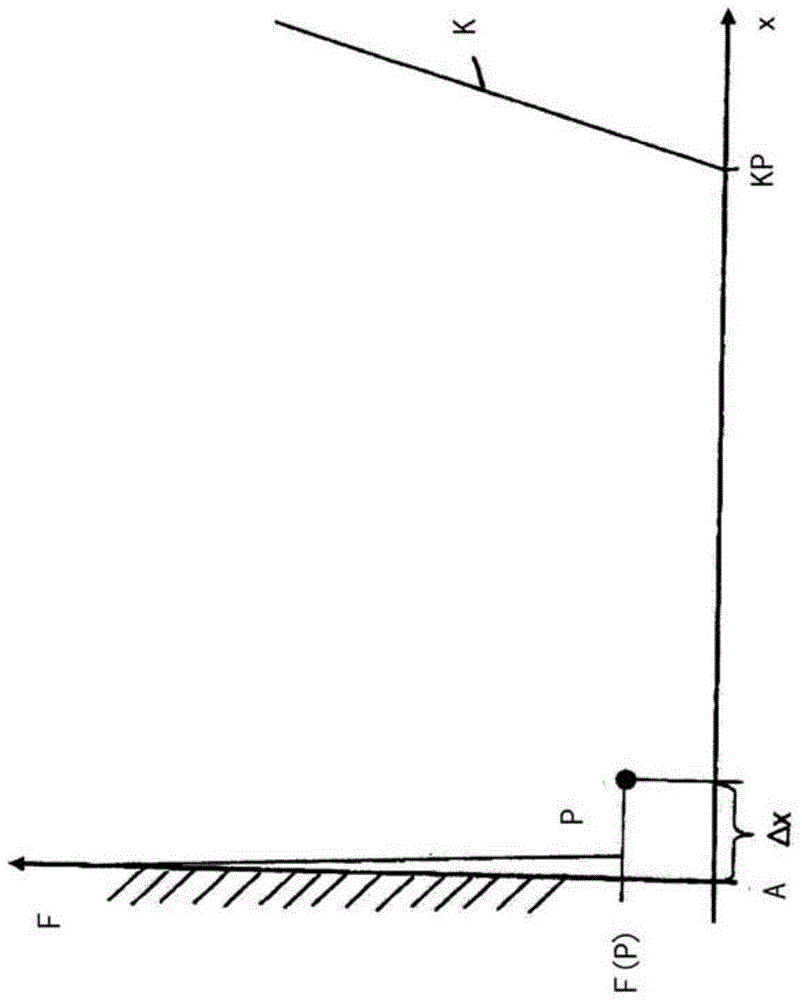

[0017] with the already described above figure 1 The difference is that figure 2 The force variation of the force F over the actuation travel x of the actuating element of an actuator is shown as a function of the plausibility check of the ascertained reference position at the stop A. FIG. For this purpose, a force threshold representing the plausibility check position P is formed for the stop A, for example in a two-stage configuration, forwardly displaced by the travel difference Δx, in that, for example, the actuating element acts with respect to the travel difference Δx A force accumulator with force F(p) is superimposed. When moving the actuating element along the actuating path x in the direction of the mechanical stop A, the actuating element first hits the front load (Vorlast) of the energy store, for example a pretensioned spring, at the plausibility check position P on the system. When moving further, the operating element is only as figure 1 Hit the mechanical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com