A Composite Core Pulling Mechanism

A technology of core-pulling mechanism and core-pulling parts, which is applied in the field of core-pulling mechanism, can solve the problems of low production efficiency and complex process of compound core-pulling, and achieve the effect of simple structure, convenient manufacture and reliable mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

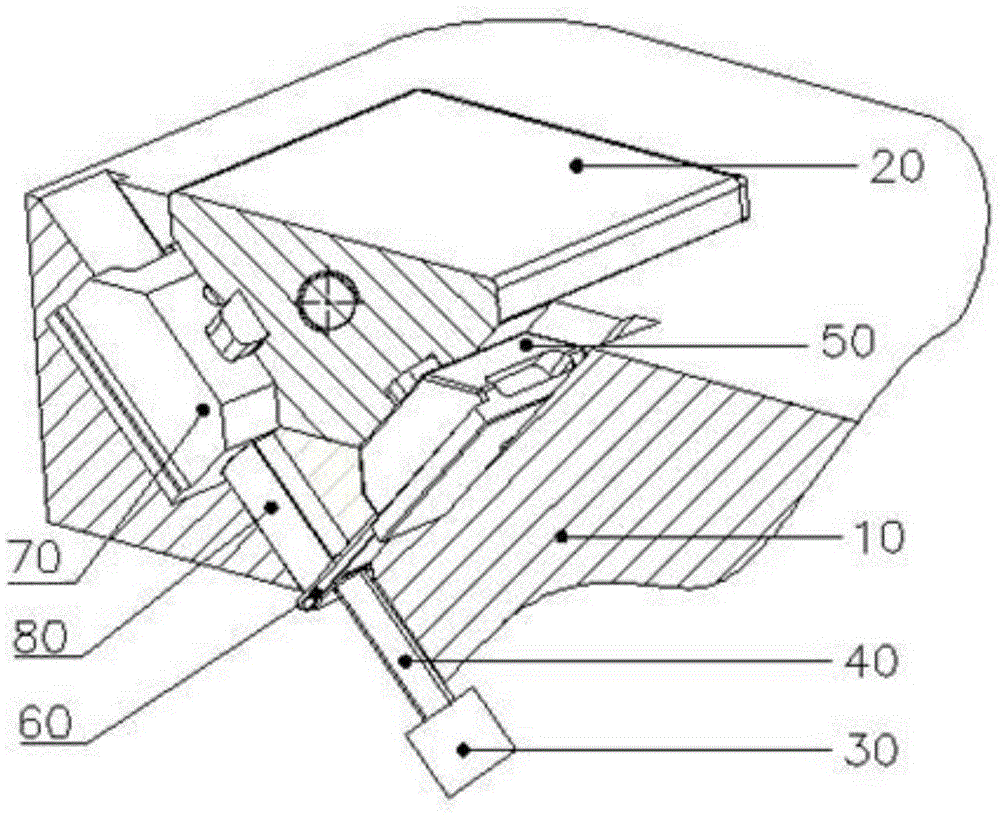

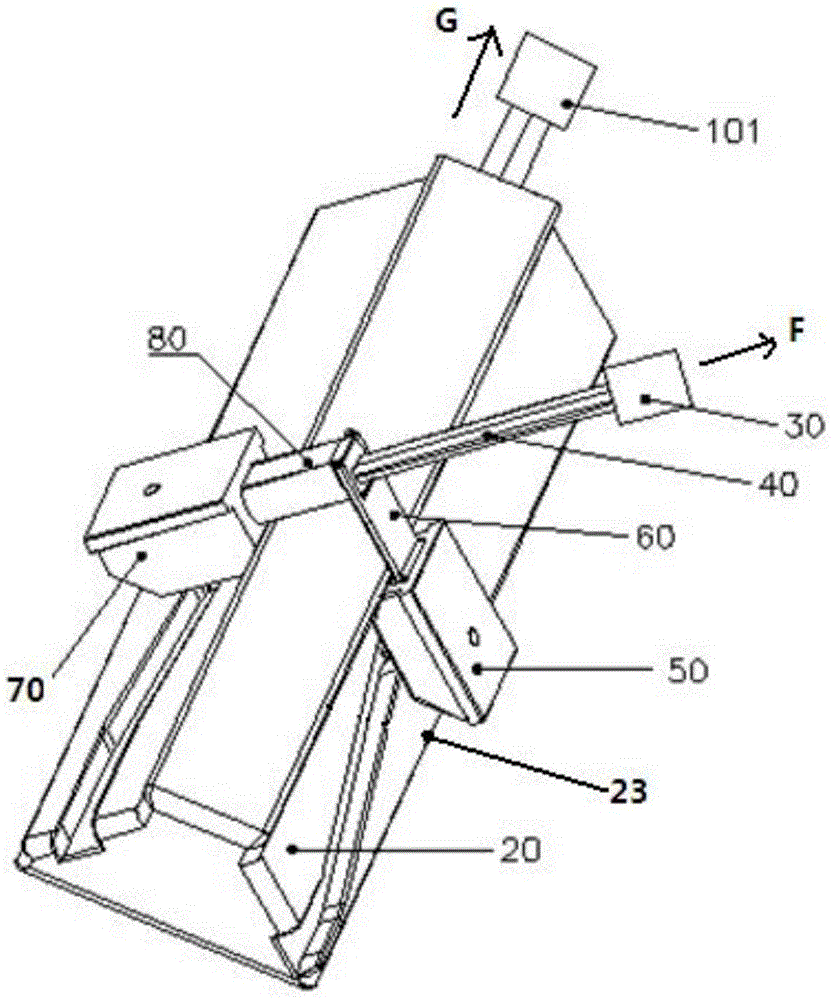

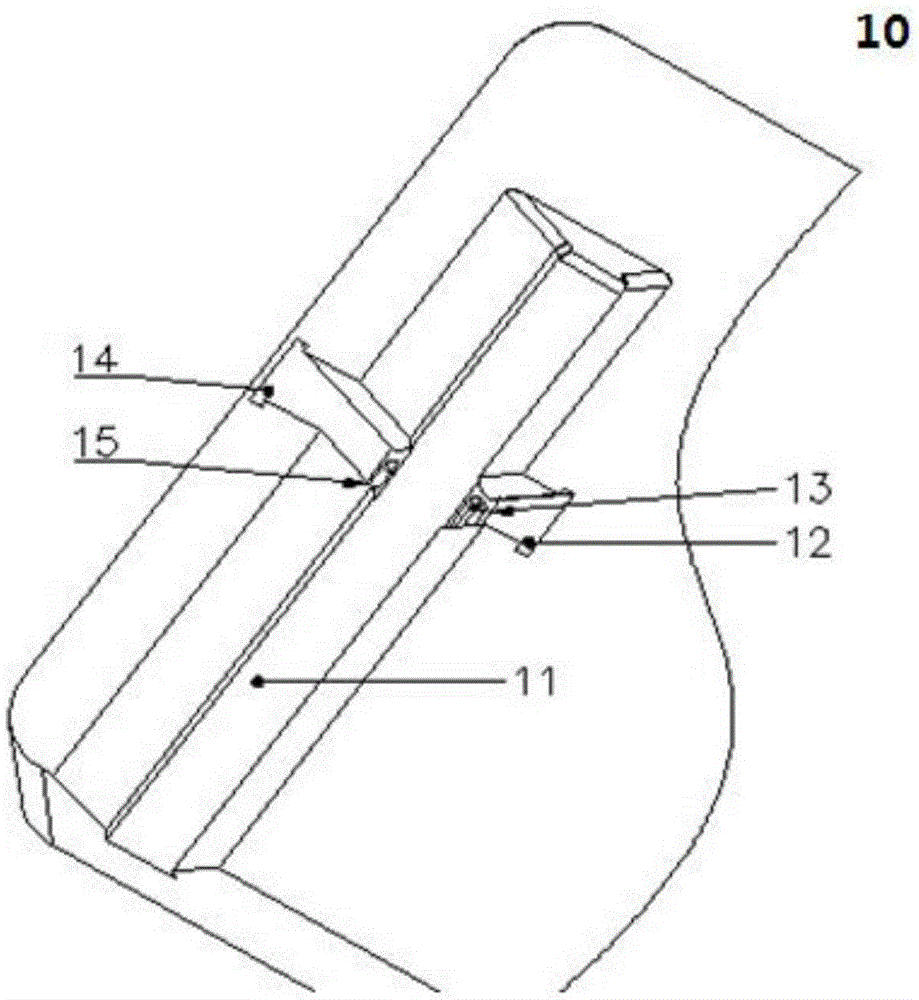

[0034] as attached Figure 1-10 As shown, it is a preferred embodiment of a compound core-pulling mechanism provided by the present invention, including a fixed mold part 10, a dial block 20, a first t-shaped slider 70, a second t-shaped slider 50, a first hydraulic pressure Cylinder 101 and the second hydraulic cylinder 30.

[0035] A compound core-pulling mechanism of this embodiment connects the first forming core-pulling part 40, the second forming core-pulling part 80 and the third forming core-pulling part 60 in the mold, and for the first forming core-pulling parts in three different directions Core member 40, the second molded core-pulling member 80 and the third molded core-pulling member 60 to complete the core-pulling, wherein the first t-shaped slider 70 is connected to one end of the second molded core-pulling member 80, and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com