Vane-shaped scramjet engine

A scramjet engine technology, applied in ramjet engines, mechanical equipment, etc., can solve the problems of poor low-speed performance, single application range, expensive test costs, etc., to achieve efficient processing, manufacturing and maintenance convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

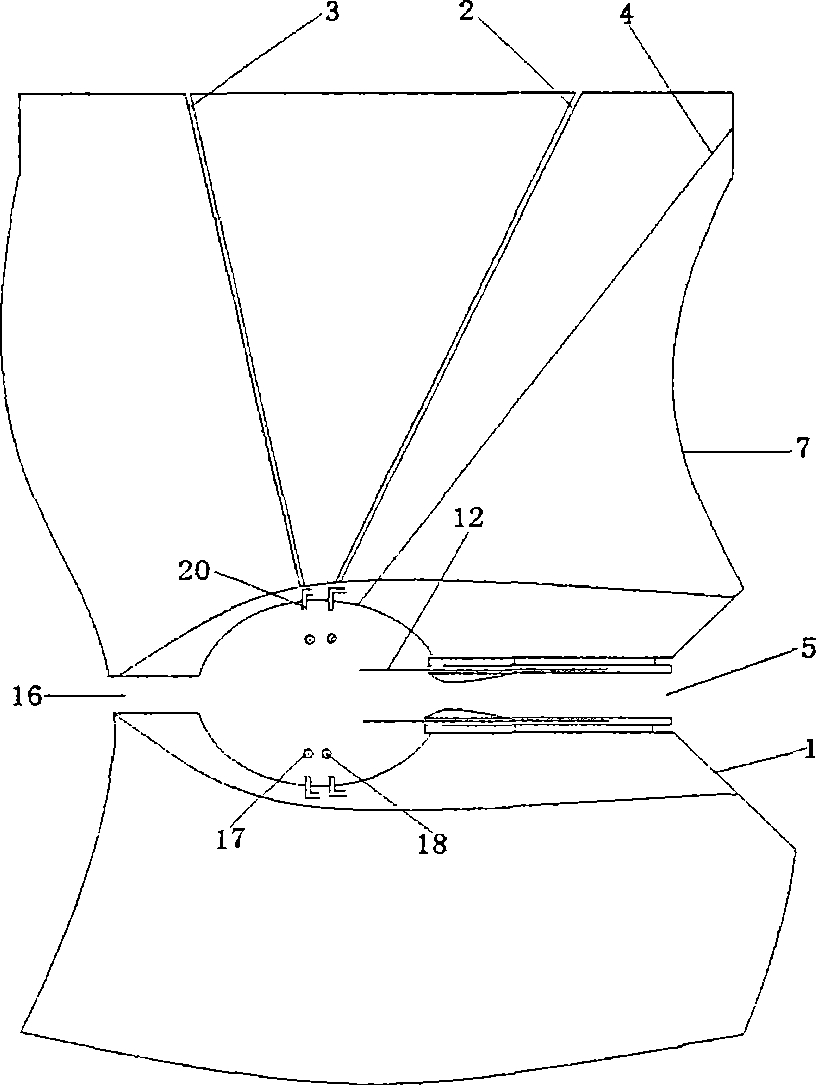

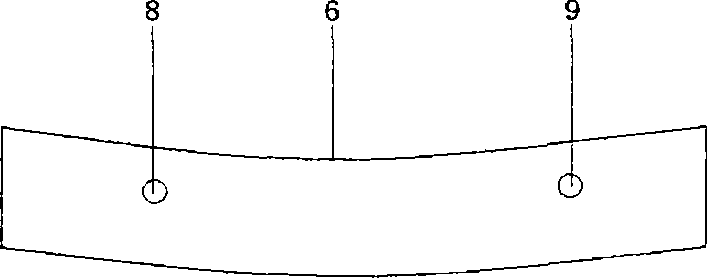

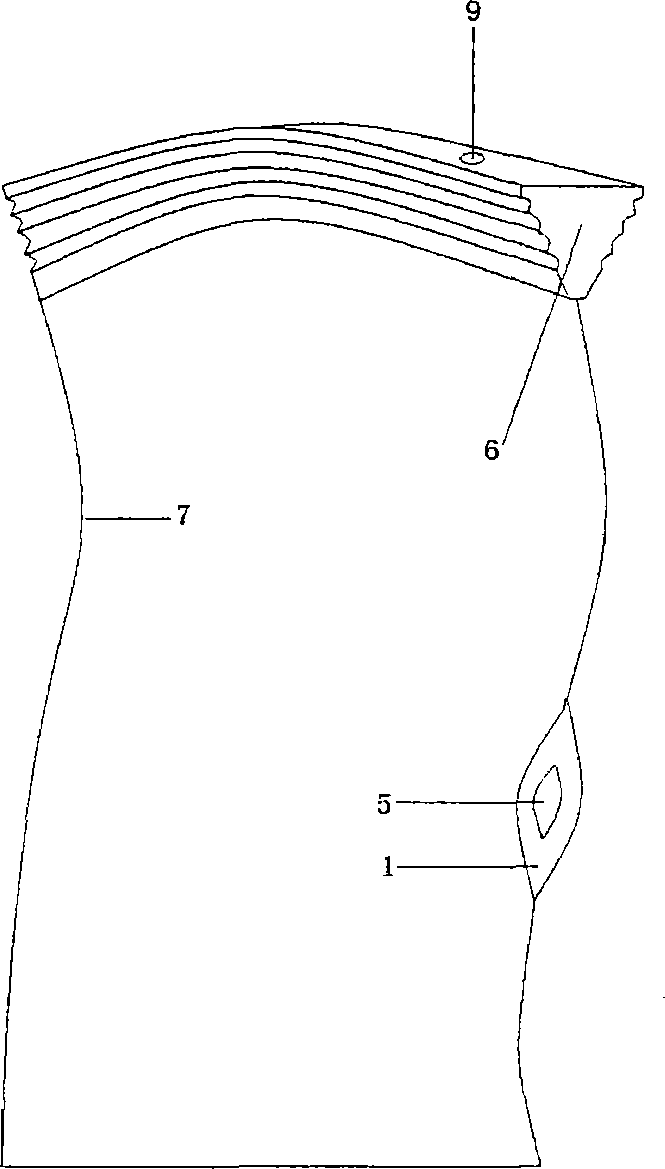

[0019] As shown in the figure, the numbers are respectively as follows: 1. Gathering port; 2. Air inlet pipe; 3. Oil inlet pipe; 4. Spark plug wire; 5. Front air inlet; Air inlet pipe hole; 9. Oil inlet pipe hole of blade root; 10. Air inlet pipe hole of blade main shaft; 11. Oil inlet pipe hole of blade main shaft; 12. T-shaped piston; 13. Central round hole of blade main shaft; 14. Blade root notch ; 15. Blade main shaft; 16. Fuel nozzle; 17. Air nozzle; 18. Fuel nozzle; 19. Shaft nut; 20. Spark plug; Air port; 24. shaft oil outlet; 25. shaft; 26. notch; 27. scramjet; 28. left combustion chamber; 29. right combustion chamber; 30. shaft convex.

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] Such as Figure 1 to Figure 8 Shown, a kind of vane-shaped scramjet engine of the present invention comprises blade 7 and scramjet engine 27. The blade root 6 of blade 7 is installed and fixed in the blade root n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com