Ester powder feeding device

A technology of feeding device and ester powder, applied in the field of ester powder feeding device, can solve the problems affecting the quality of production products, different mixing ratios, etc., and achieve the effect of good quality and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

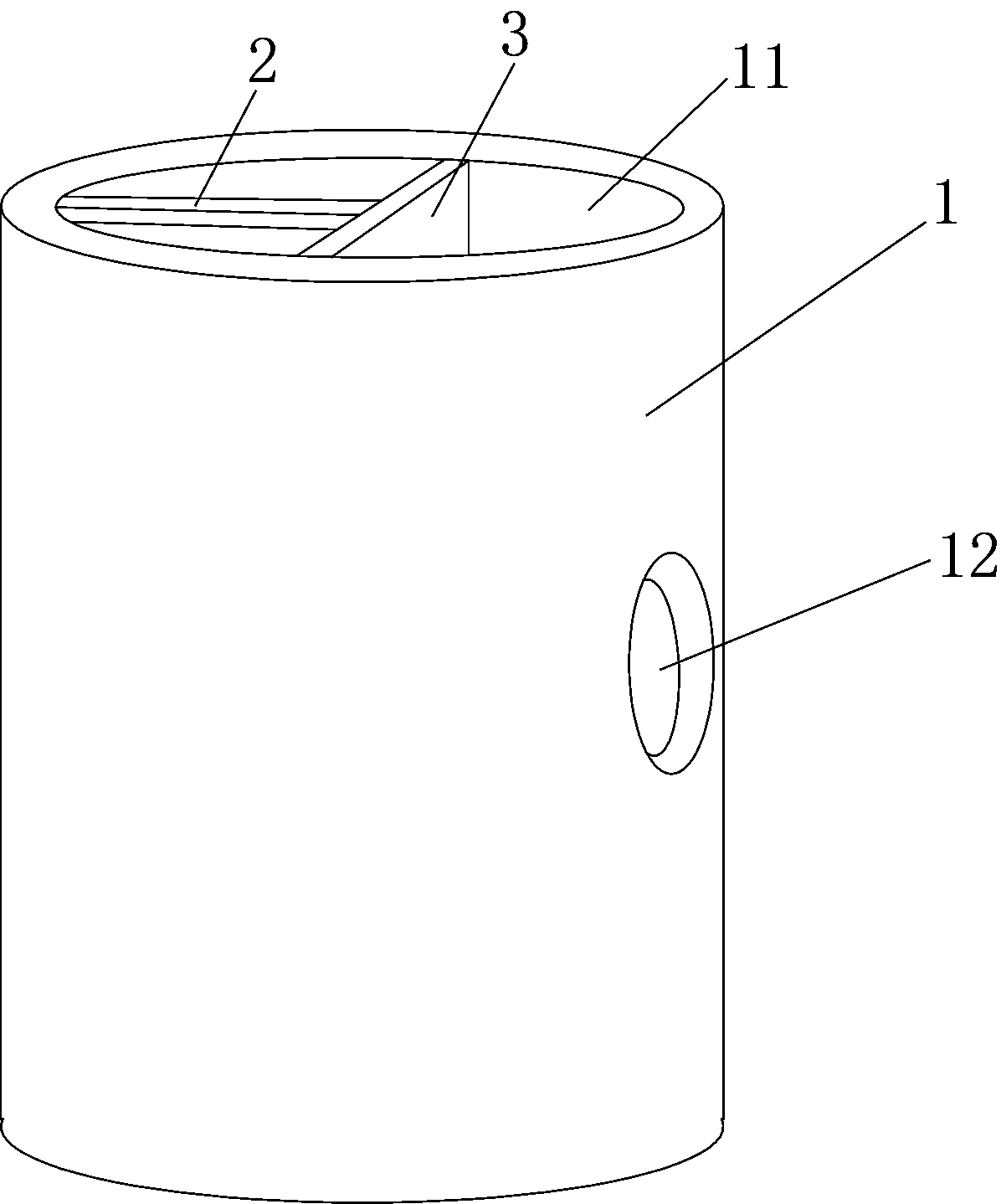

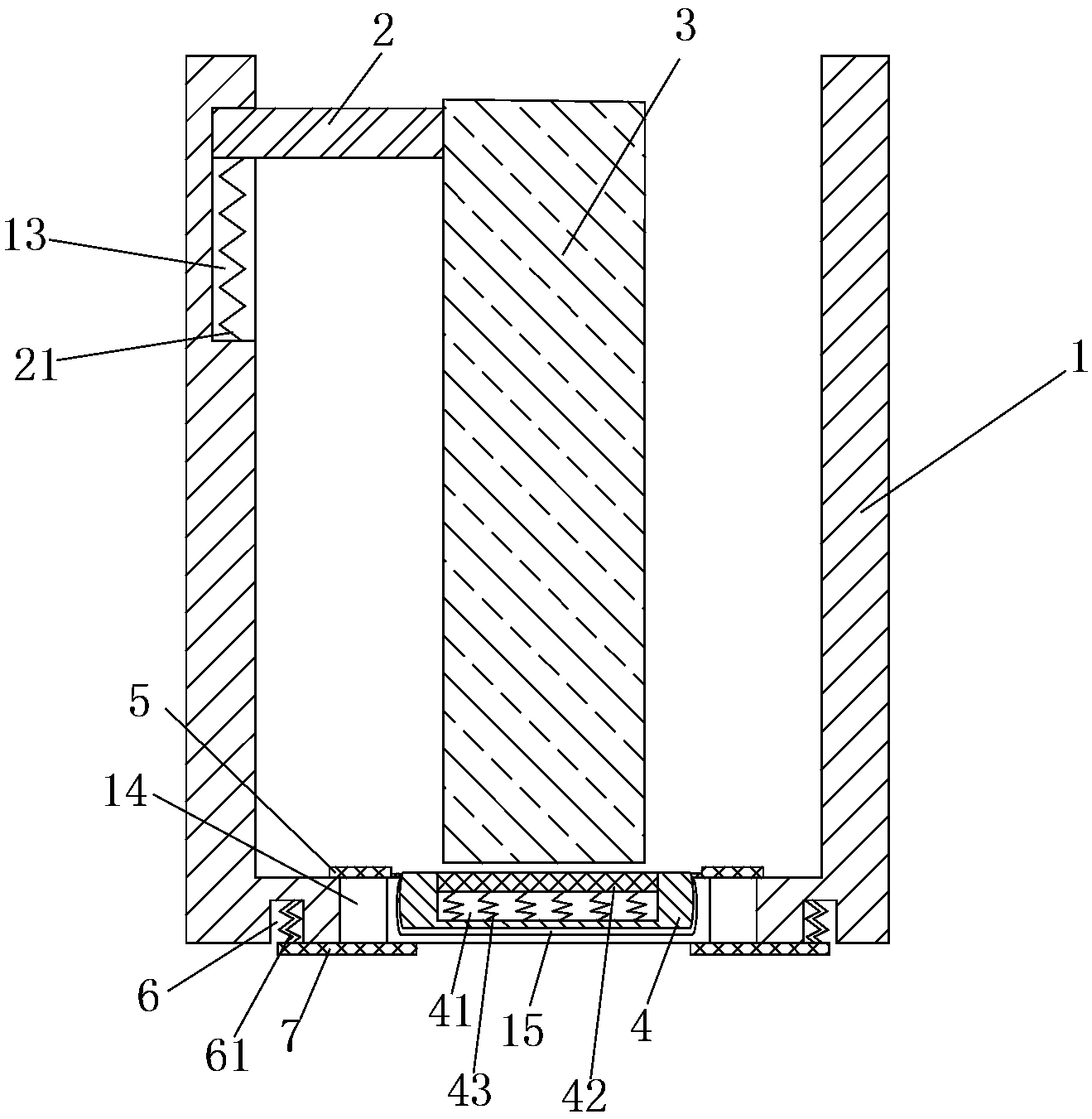

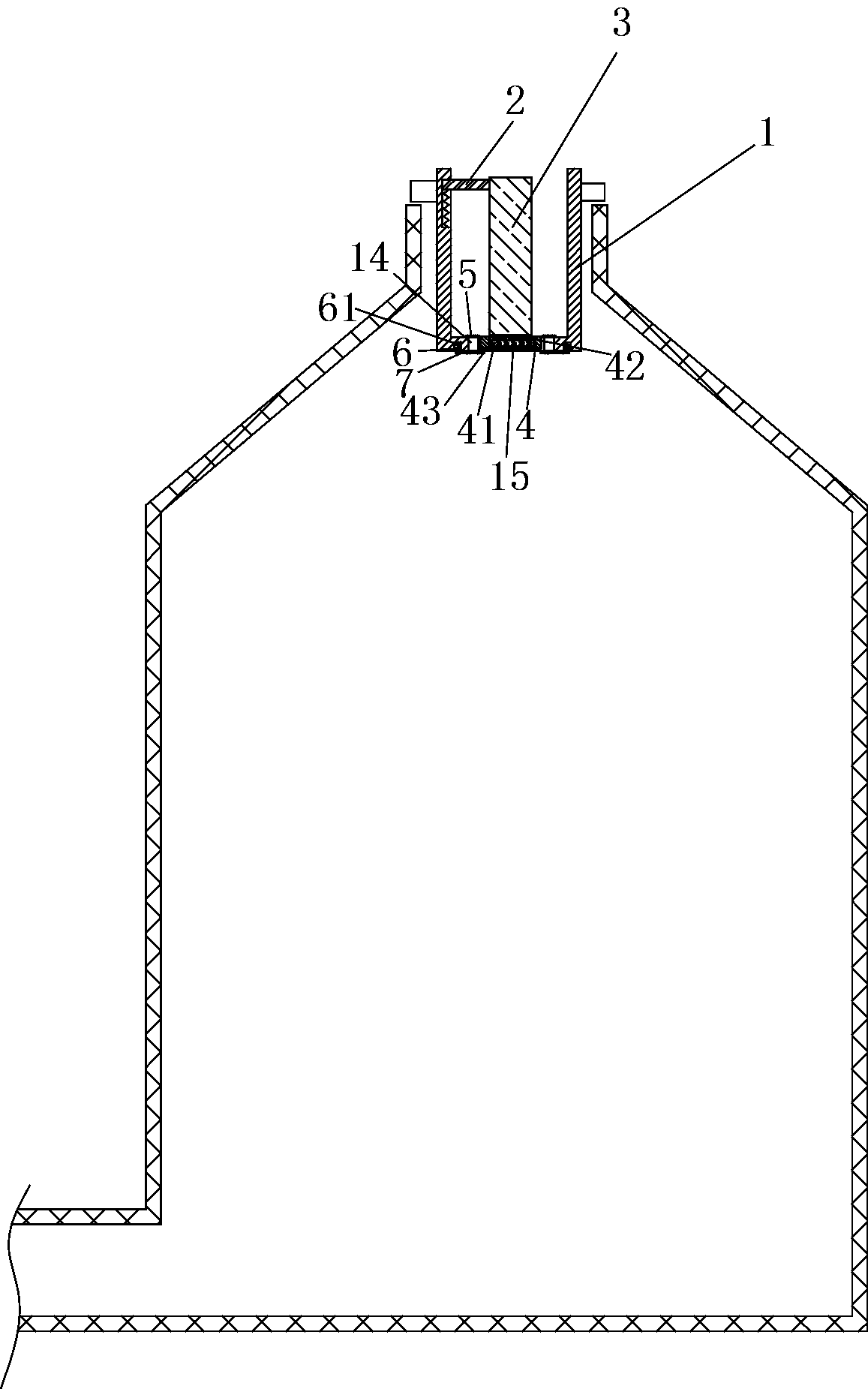

[0013] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1-Figure 3 , an ester powder feeding device, comprising a device body 1 with a hollow interior, and a bracket can be arranged on the outer surface of the device body 1 for supporting the device body 1 at the opening of the esterification kettle. The upper side of the device body 1 is provided with a feed port 11, and a discharge port 12 is provided on the side of the device body 1, and the discharge port 12 can be opened at the middle position from the bottom to the top of the device body 1. The inner side wall of the device body 1 is provided with a chute 13, and the chute 13 can be opened near the feeding port 11, and the connecting rod 2 is slidably connected in the chute 13, and the connecting rod 2 is connected with the lower end of the chute 13. There is a No. 1 elastic component 21 connected between the bottom surfaces, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com