Cutter device used for plastic bag production

A production process, plastic bag technology, applied in packaging, transportation and packaging, rigid/semi-rigid container manufacturing, etc., can solve the problems of plastic bags with thick ink, strong three-dimensional effect, slow printing speed, etc., to achieve stable and effective Sequential continuous production, practical and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

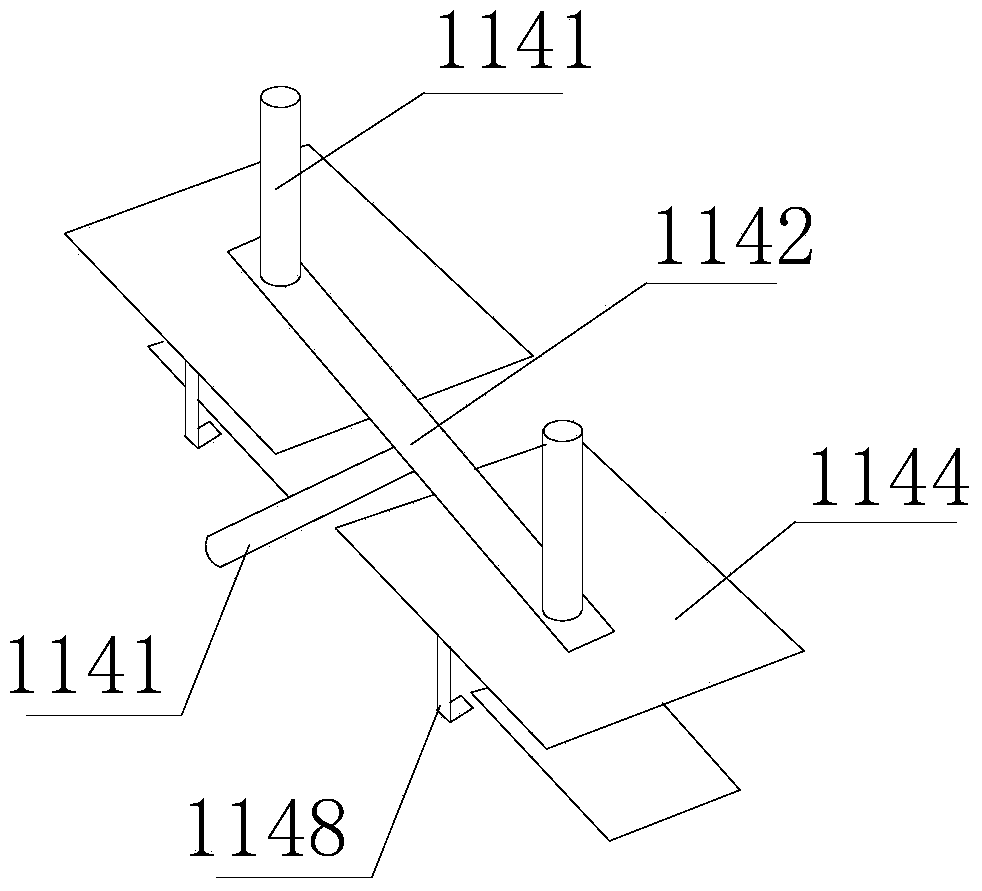

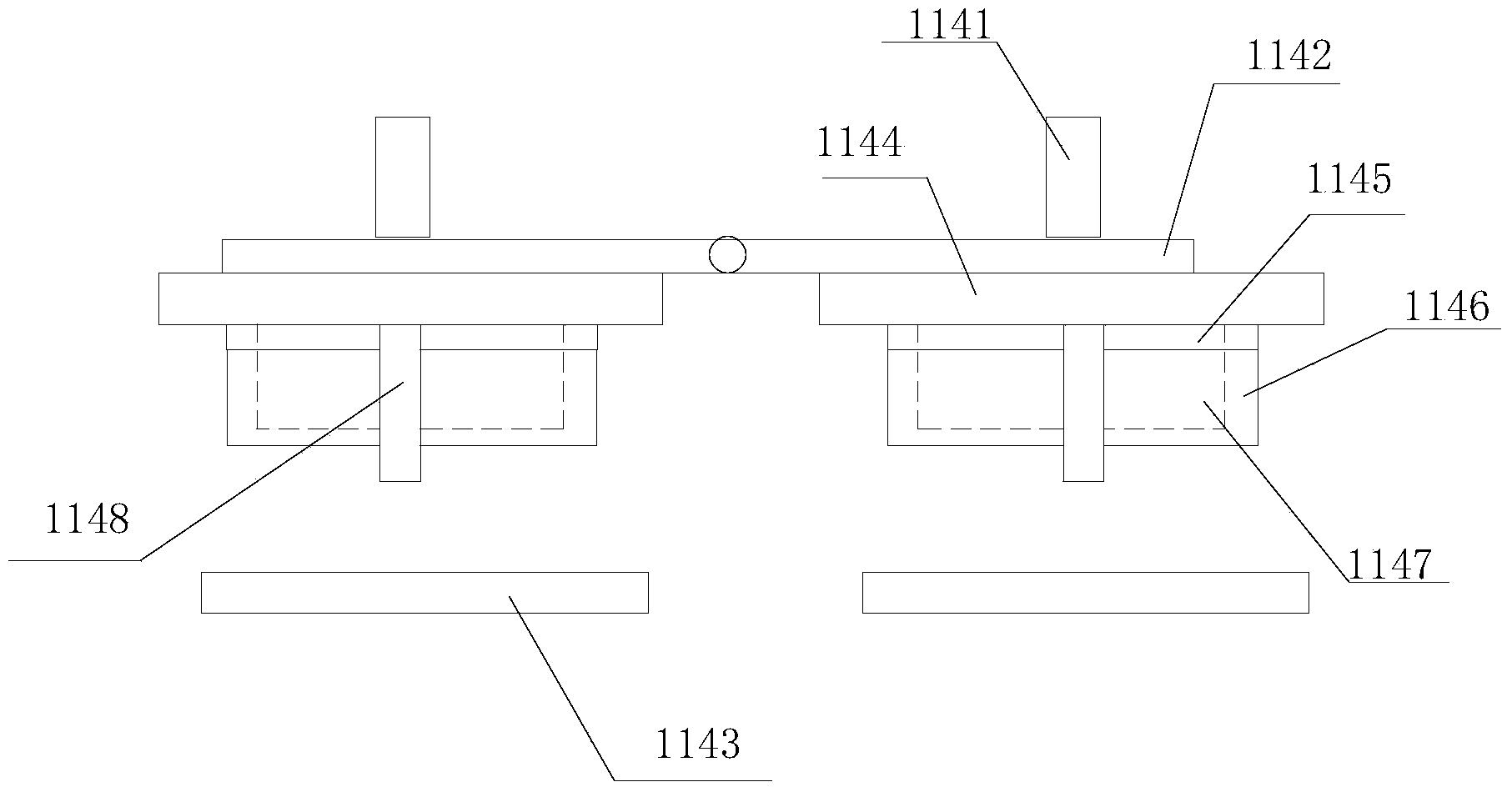

[0016] Such as figure 1 and figure 2 As shown, the cutter device of this embodiment includes three hydraulic cylinders 1141, a connecting plate 1142, two cutter mechanisms and two cutting discs 1143, and the cutter mechanism includes a top seat 1144, a buffer member 1145, a sponge 1146, Cutter 1147 and push blade 1148, the top seat 1144 is connected to the connection plate 1142 respectively, two hydraulic cylinders 1141 are vertically arranged at both ends of the connection plate 1142, and the two hydraulic cylinders 1141 are located between the corresponding top seats 1144 Above, the third hydraulic cylinder 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com