High-precision abnormal data detection and repair method in blast furnace smelting process

A blast furnace smelting and data technology, applied in the direction of instruments, simulators, control/regulation systems, etc., can solve the problem of low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further described through specific implementation below.

[0022] The specific steps are:

[0023] 1. Detect the number of missing values m in the sample data {y(1), y(2), ... y(k), ... y(L)} collected on-site at the blast furnace in group L, and the number of iron times x corresponding to the missing values i , and record the vector M=[x 1 x 2 … x m ] T .

[0024] 2. Calculate the sample mean and deviation (missing data does not participate in the calculation), sample mean: Sample bias:

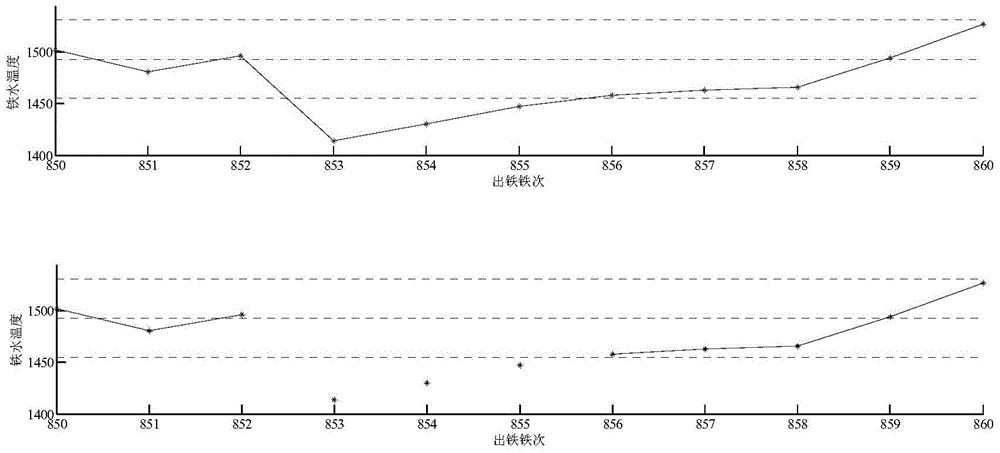

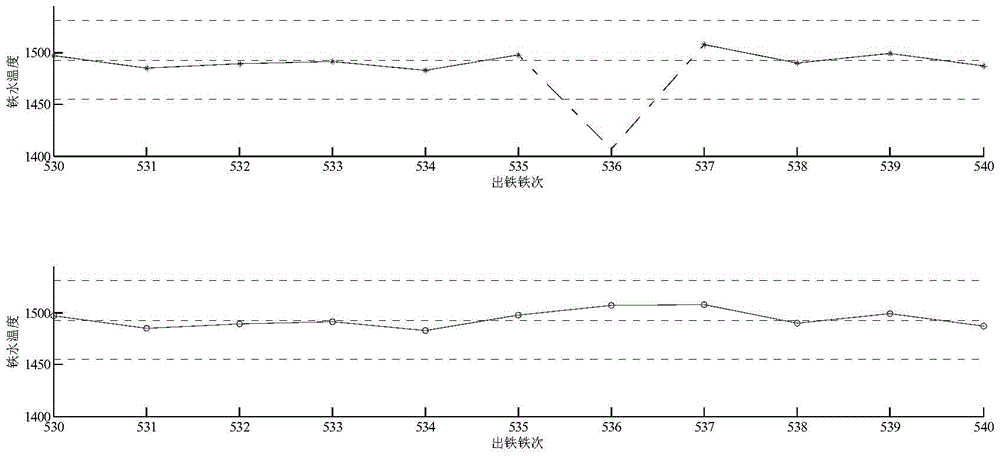

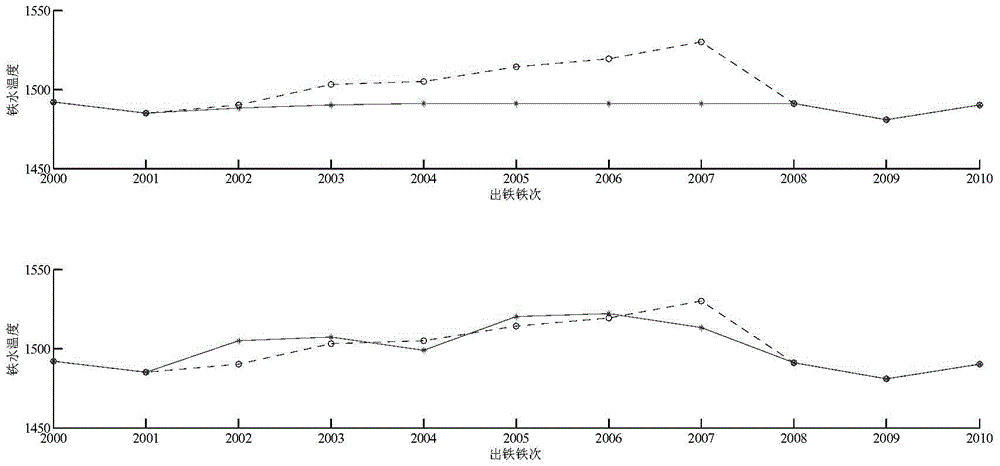

[0025] 3. The 3σ rule globally detects the data {y(1), y(2), ... y(k), ... y(L)}, and records the iron times x whose data values are outside the μ±3σ boundary i ,x i It is the number of times that abnormal data may appear; then in x i Do local analysis at all times, and calculate |y(x i )-y(x i-1 )| and |y(x i+1 )-y(x i )|, if the above differences are greater than 3σ, but |y(x i+2 )-y(x i+1 )| and |y(x i+3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com