Unidirectional positioning handle

A one-way positioning and handle technology, which is applied in the direction of instruments, devices for preventing/limiting/recovering the movement of parts of the control mechanism, mechanical control devices, etc., can solve the problem of no one-way locking and positioning device, etc., and achieve small friction coefficient, Not easy to wear and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

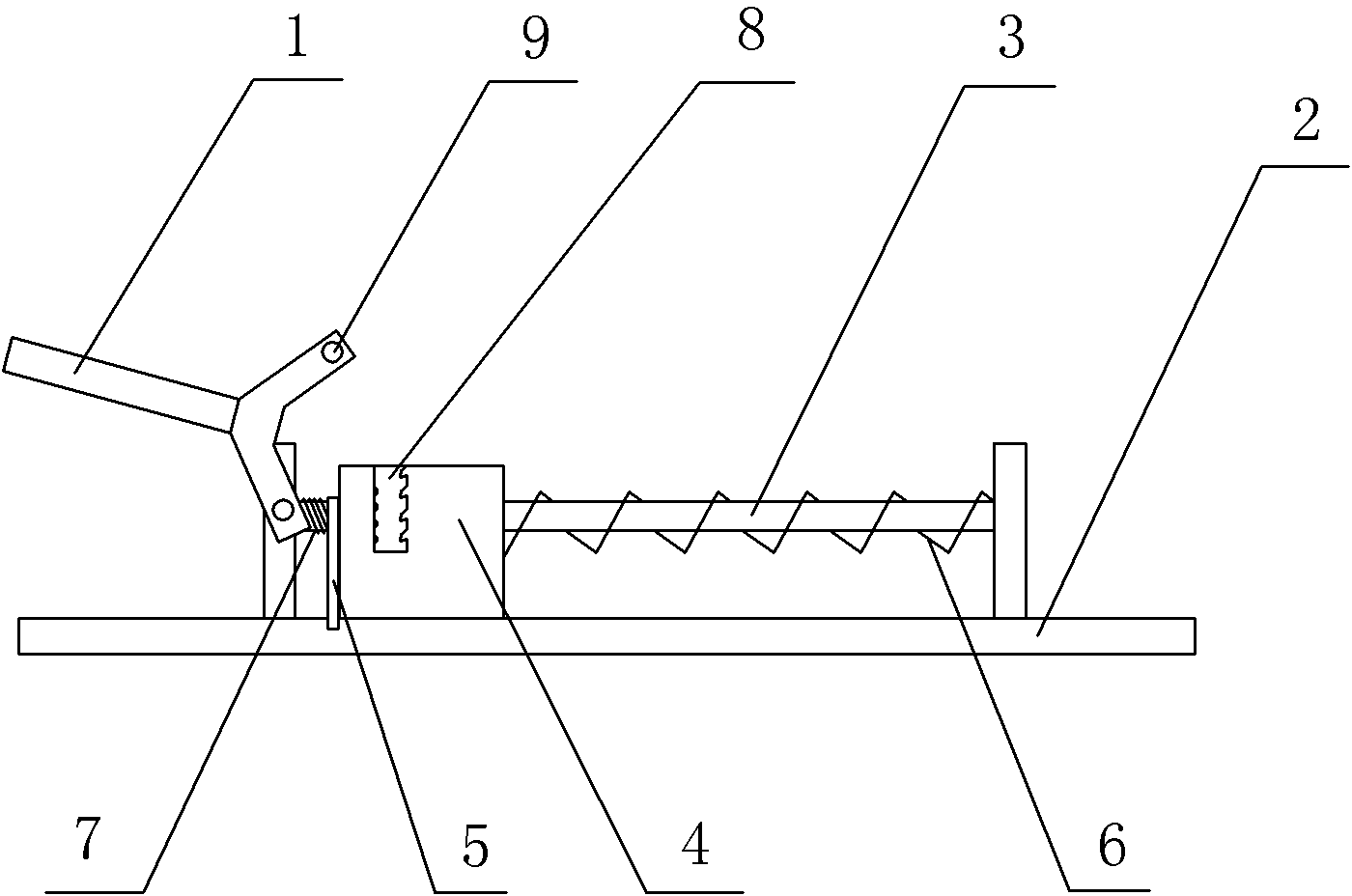

[0015] The reference signs in the drawings of the specification include: handle body 1, seat body 2, pole 3, locking block 4, limit block 5, first compression spring 6, second compression spring 7, bar-shaped hole 8, pin shaft 9.

[0016] Such as figure 1 As shown, a one-way positioning handle in this embodiment includes a seat body 2, a handle body 1, a support rod 3, a locking block 4, a limit block 5, and a first compression spring 6 sleeved on the support rod 3. And the second stage clip 7. Both ends of the strut 3 are detachably connected to the base body 2 . The right end of the limiting block 5 is movably connected on the base body 2, the locking block 4 is slidably connected on the pole 3, the right end of the first compression spring 6 is against the base body 2, the left end is against the right side of the locking block 4, and the locking block 4 The left side offsets with the limit block 5. The left end of the second compression spring 7 is against the seat bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com