A liquid damping shock absorber for engineering machinery

A liquid damping, engineering machinery technology, applied in shock absorbers, shock absorbers, mechanical equipment, etc., can solve the problem of affecting the performance and life of various engine parts and the whole machine, affecting the driver's riding comfort, and reducing work efficiency. and other problems, to achieve the effect of reducing the secondary hardening effect, broadening the effective vibration isolation frequency band, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

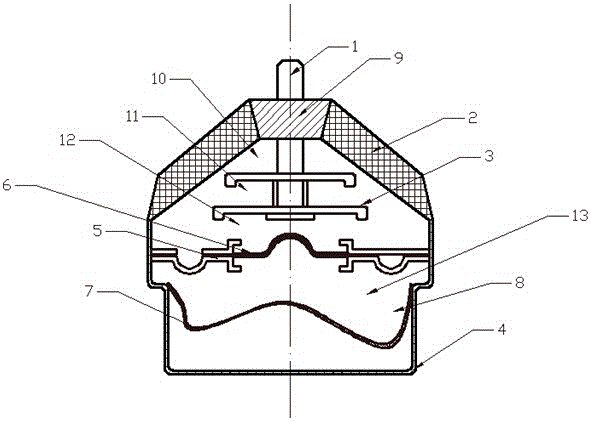

[0016] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0017] Such as figure 1 As shown, a liquid damping shock absorber for construction machinery, including connecting bolts 1, rubber main spring 2, two throttle plates 3, metal shell 4, inertia channel 5, decoupling plate 6, rubber bottom film 7. Embedded to the connecting seat 9 on the top of the rubber main spring 2. The rubber main spring 2 is connected to the upper end of the metal casing 4, and the rubber main spring 2 and the metal casing 4 form a closed liquid chamber. The connecting bolt 1 is fixedly connected to the connecting seat 9 , the throttle plate 3 is located in the sealed liquid chamber, and the throttle plate 3 is fixedly connected to one end of the connecting bolt 1 . The inertia channel 5 is fixedly connected to the inner wall of the metal housing 4 , the inertia channel 5 is located under the throttle plate 3 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com