Hose filling and tail sealing machine correction device and use method thereof

A technology of correcting device and end-sealing machine, applied in packaging and other directions, can solve problems such as affecting product aesthetics, hose asymmetry, hose inclination and deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

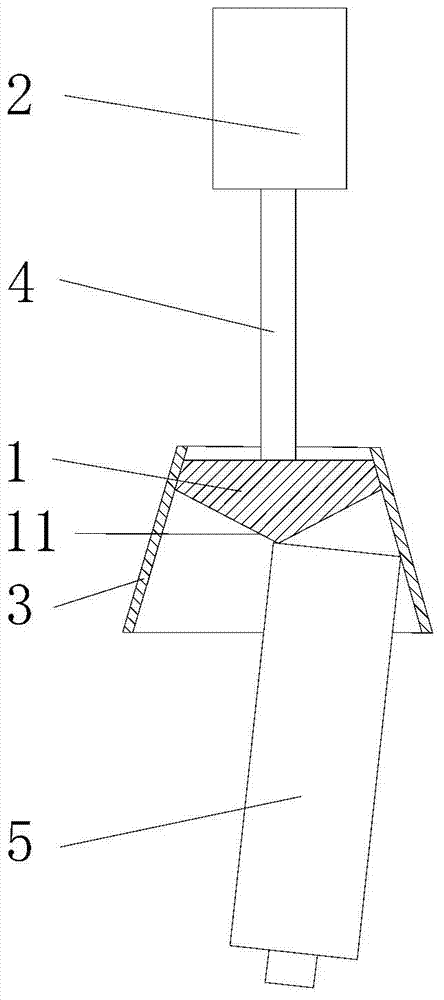

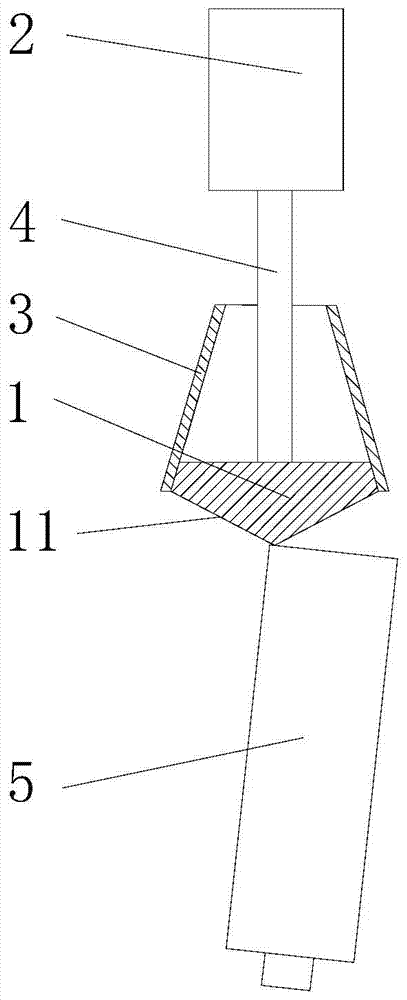

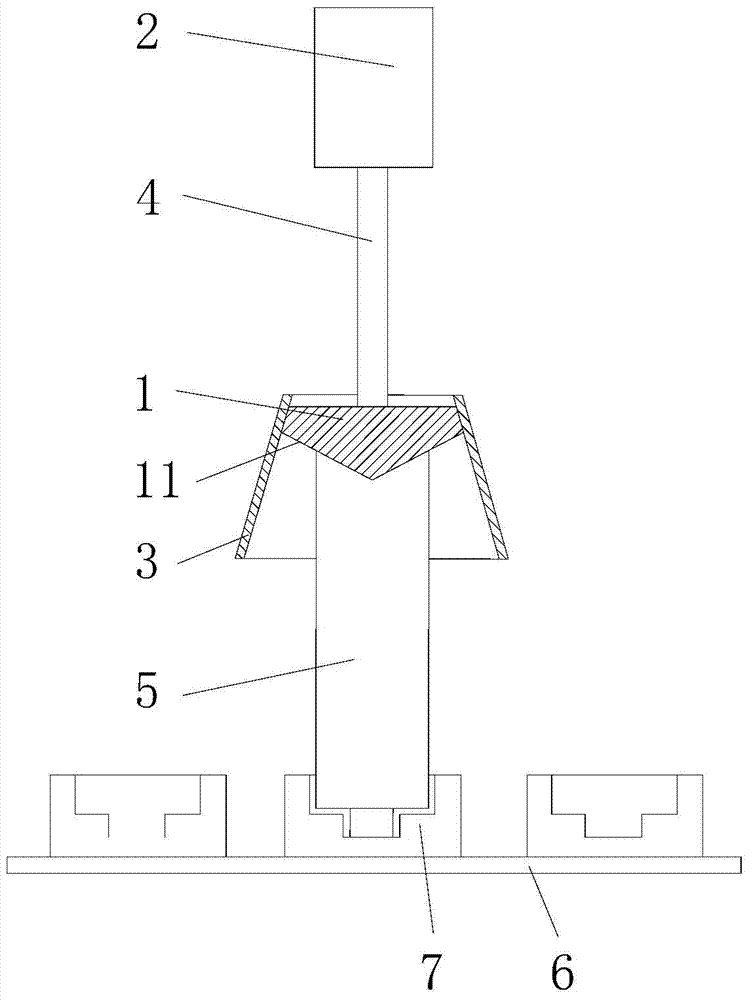

[0019] In further embodiments of the present invention, please continue to refer to Figure 1 to Figure 3 shown. The inner wall of the protective cover 3 is a smooth surface.

[0020] In a further embodiment of the present invention, the protective cover 3 is made of elastic material, and the use of elastic material facilitates the protective cover 3 to cover the pressing part 1 .

[0021] In a further embodiment of the present invention, the protective cover 3 is coaxially arranged with the pressure piece 1 .

[0022] In a further embodiment of the present invention, there is a piston top rod 4 between the pressing piece 1 and the external cylinder 2 , and the pressing piece 1 is connected to the external cylinder 2 through the piston top rod 4 .

[0023] On the basis of the above, the present invention also has the following usage methods:

[0024] Please continue to see Figure 1 to Figure 3 shown. When the hose filling and sealing machine is working, the hose 5 is pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com