Vibration dampers, especially piston rod dampers for motor vehicles

A technology of piston rod and shock absorber, applied in the direction of shock absorber, spring/shock absorber, shock absorber, etc., can solve the problems of vibration shock absorber damage, end stop 23 disengagement, etc. Stable force and reliable locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Like features are provided with like reference numerals.

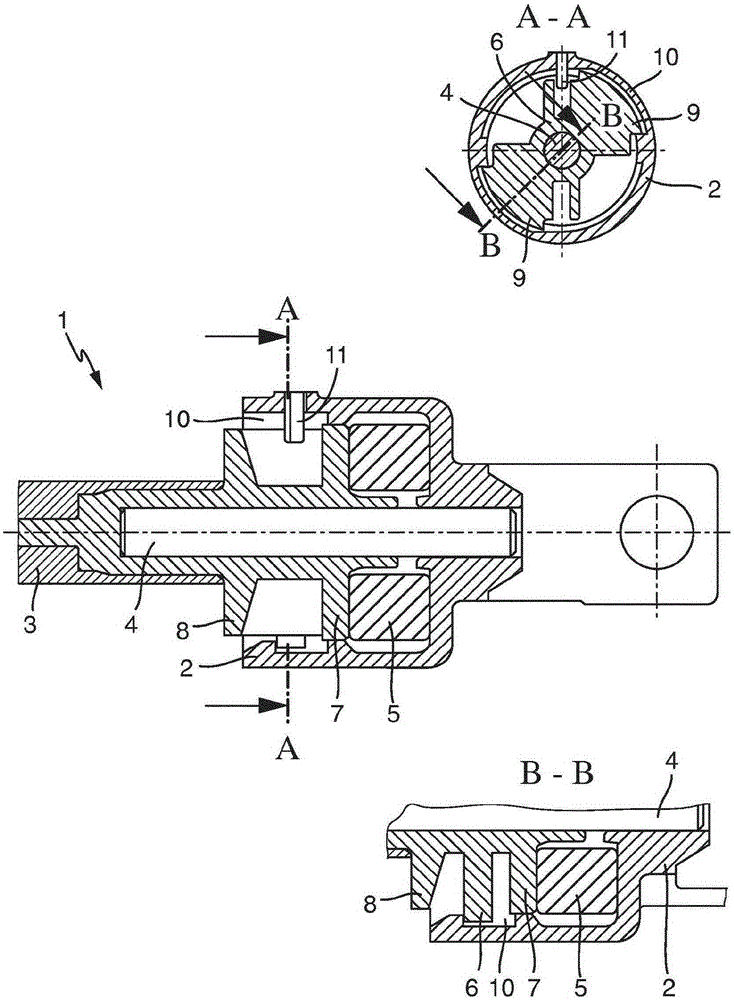

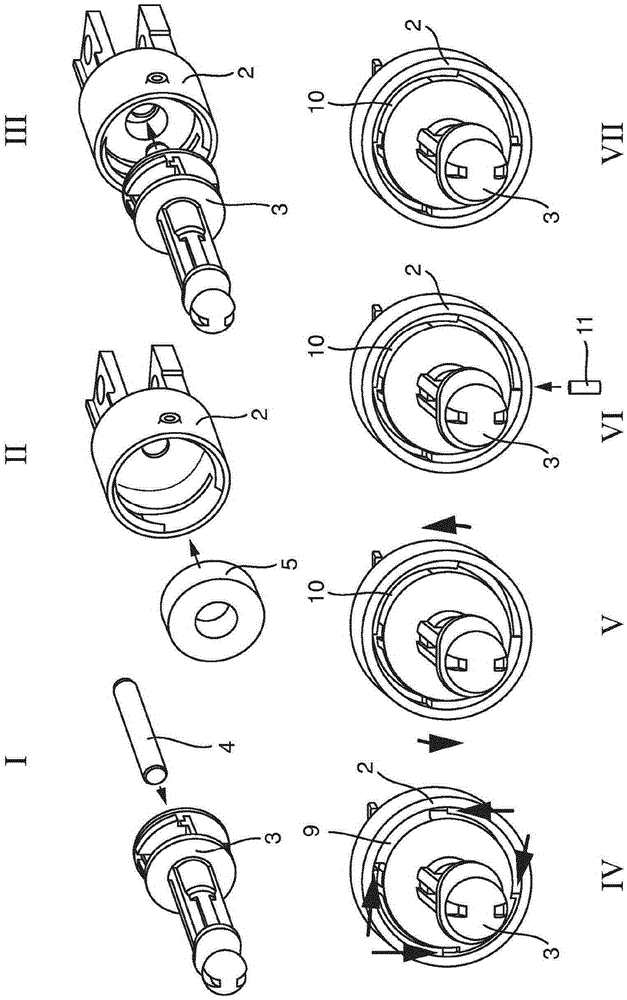

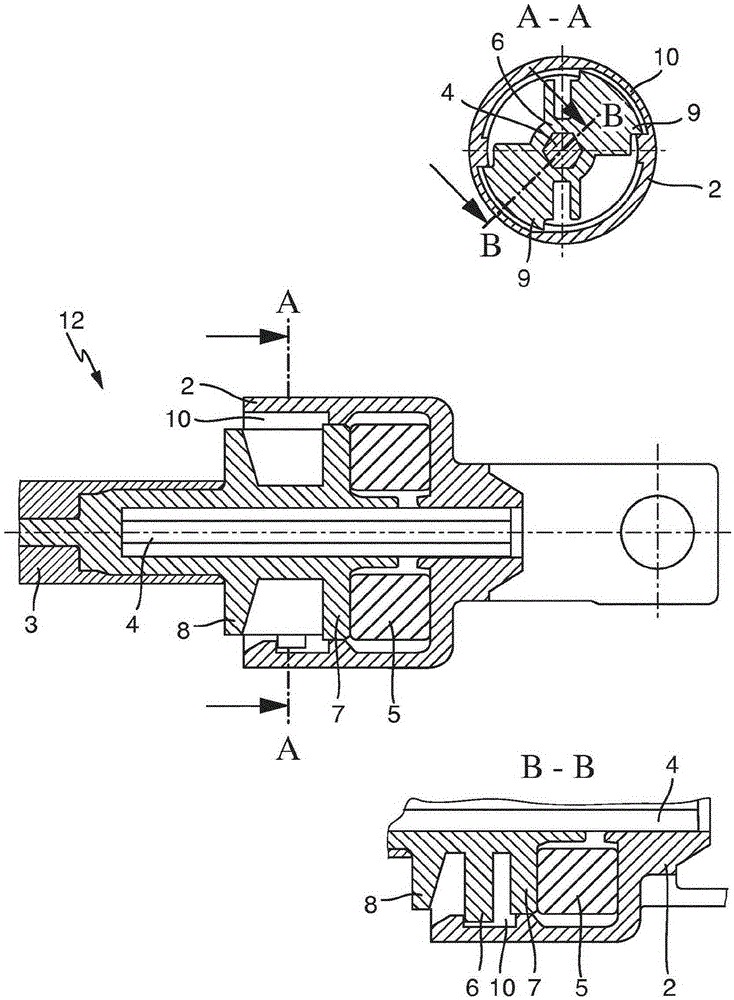

[0021] exist figure 1 shows a piston rod damper 1 which is designed to connect a clutch pedal to a master cylinder of a clutch operating system in a motor vehicle. The piston rod damper 1 is formed by a damper housing 2 into which a piston rod 3 is introduced. The damper housing 2 is connected here to a clutch pedal, not shown further, while the piston rod 3 is guided on a master cylinder, likewise not shown, of the clutch operating system of the motor vehicle,

[0022] The piston rod 3 surrounds a cylindrical pin 4 which protrudes beyond the piston rod 3 in the direction of the damper housing 2 . In this case, the end of the pin 4 engages in the damping housing 2 , wherein the pin 4 is fixedly seated in the piston rod 3 , while the pin 4 is held in a floating bearing in the damping housing 2 . A damping element in the form of a rubber damper 5 is arranged within the damping housing 2 between the damping hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com