Blowing mould

A technology of blow molding molds and moulds, which is applied in the field of moulds, can solve the problems of unsuitability for small enterprises, complex structures, and high investment costs, and achieve the effects of simple structure, low manufacturing cost, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

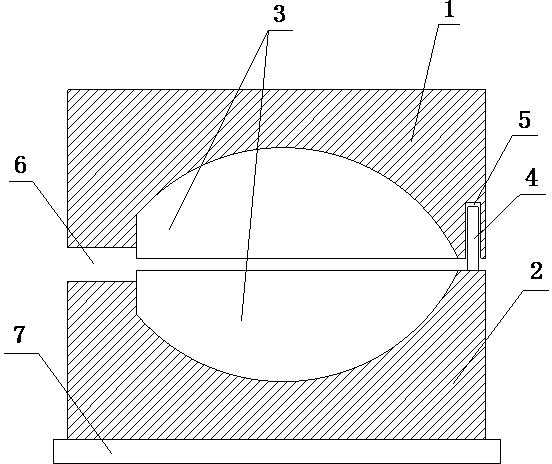

[0013] Such as figure 1 As shown, a blow molding mold of the present invention includes a mold body, the mold body is composed of a first mold body 1 and a second mold body 2, and a mold cavity 3 is opened in the middle of the first mold body 1 and the second mold body 2 At least three ejector pins 4 are fixed around the mold cavity 3 of the second mold body 2, and holes 5 matched with the ejector pins 4 of the second mold body 2 are arranged around the first mold body 1, and the mold cavity 3- There is a blow molding hole 6 on the side, and a shock-absorbing gasket 7 is arranged at the bottom of the second mold body 2, and the thickness of the shock-absorbing gasket 7 is 2-3 cm.

[0014] The invention has the advantages of simple structure, convenient use, low manufacturing cost, good shock absorbing effect, good use effect and stable performance, and is suitable for small enterprises.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com