Bumper mounting structure with mounting direction changing function

A technology of installation structure and installation direction, applied to bumpers and other directions, can solve the problems of increasing core pulling, increasing mold cost, and large bumper molds, so as to reduce processing difficulty, save mold costs, and ensure smooth installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

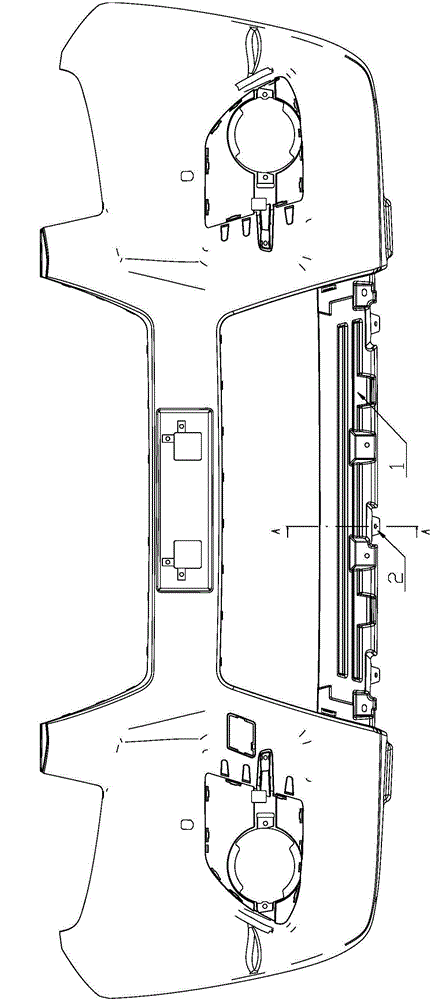

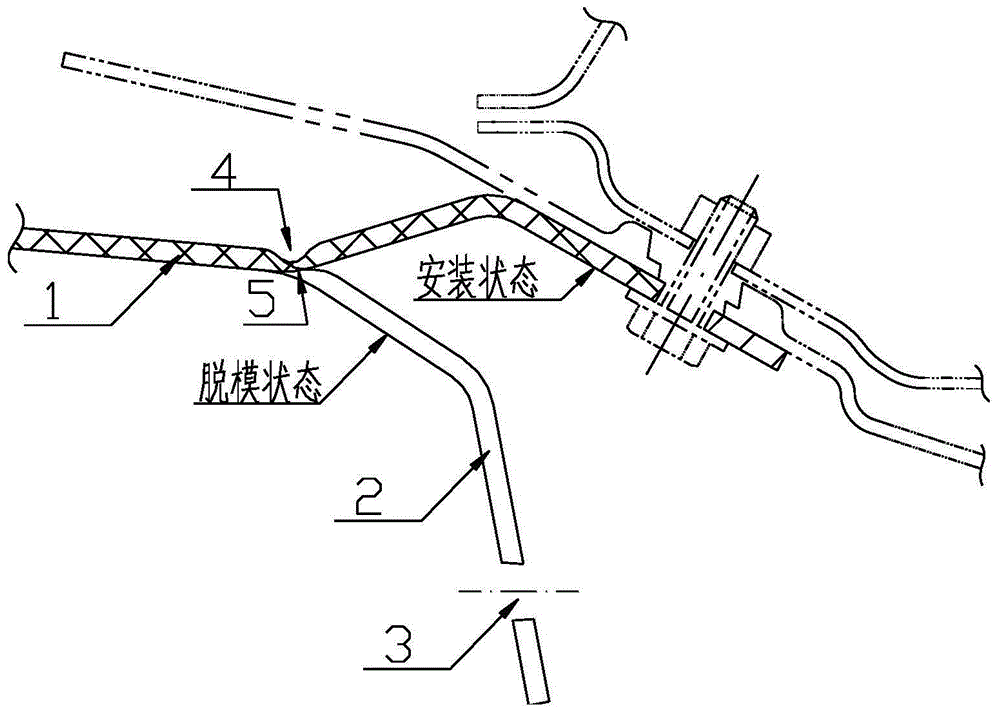

[0017] Such as figure 1 and figure 2 As shown, the present invention has made a new design in that: add a glue reducing groove 4 at the root of the connecting piece 2 of the front bumper 1 of the automobile, the effect of the reducing glue groove 4 is to allow a turning here to form a curved portion 5 , so that the connecting piece 3 will not break when turning. By adding the glue reducing groove 4, the technical problem that the installation direction of the structural hole is not consistent with the demoulding direction, and the core must be pulled out in the demoulding direction is solved.

[0018] Such as figure 2 As shown, the thickness of the glue reducing groove 4 is 1-1.5mm, and the width is 3-6mm. Preferably, the thickness of the glue reducing groove 4 is 1.2mm, and the width is 5mm.

[0019] When making the mould, process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com