Sealing inspection device for precision welding products

A technology of precision welding and inspection device, applied in liquid/vacuum measurement for liquid tightness, by detecting the appearance of fluid at leakage points, etc., it can solve the problems of high sensitivity, difficult leakage points, low detection efficiency, etc. The effect of simple operation, avoidance of deviation, and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0018] Referring to the accompanying drawings, embodiments of the present invention include:

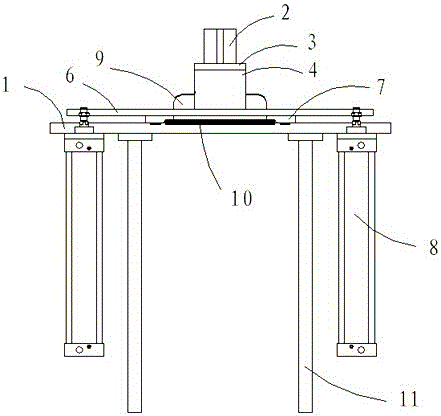

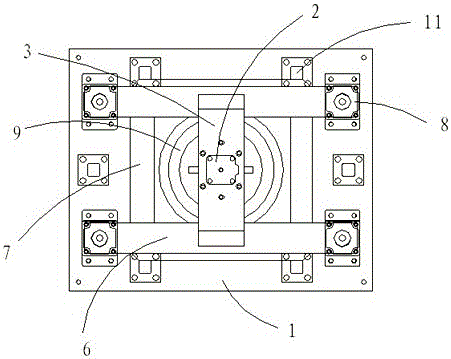

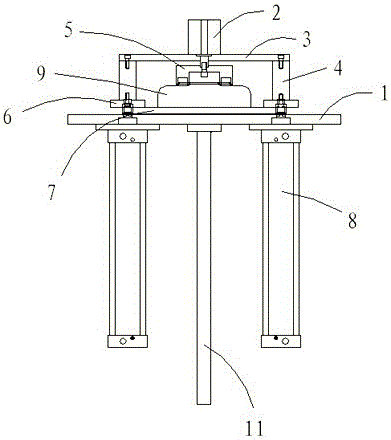

[0019] A sealing test device for precision welding products, comprising a workbench 1 equipped with six pillars 11, the upper part of the workbench 1 is a sealing and pressing structure, and the lower part of the workbench 1 is an automatic top pressing structure.

[0020] The sealing and pressing structure includes, from top to bottom, the first cylinder 2, the support plate 3 supporting the first cylinder 2, the pad iron 4 of the frame support plate 3, and the pressure plate 5 for pressing the boss part of the workpiece 9 to be measured. , the fixed p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap