Tracheostomy tubes

A technique of tracheotomy and intubation, which is applied in the direction of tracheal intubation, medical devices, and other medical devices, and can solve problems such as weakening the degree of warping and collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

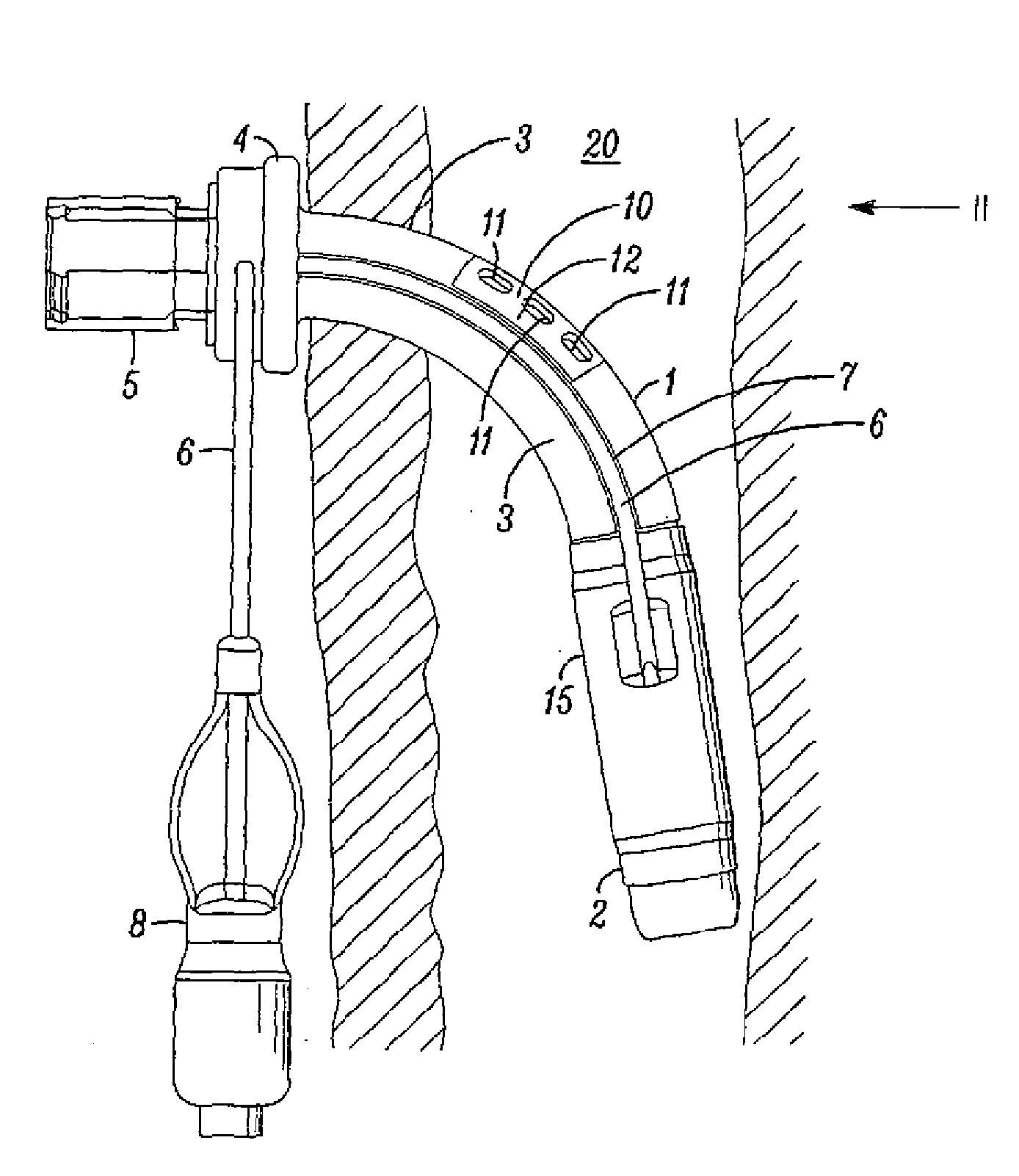

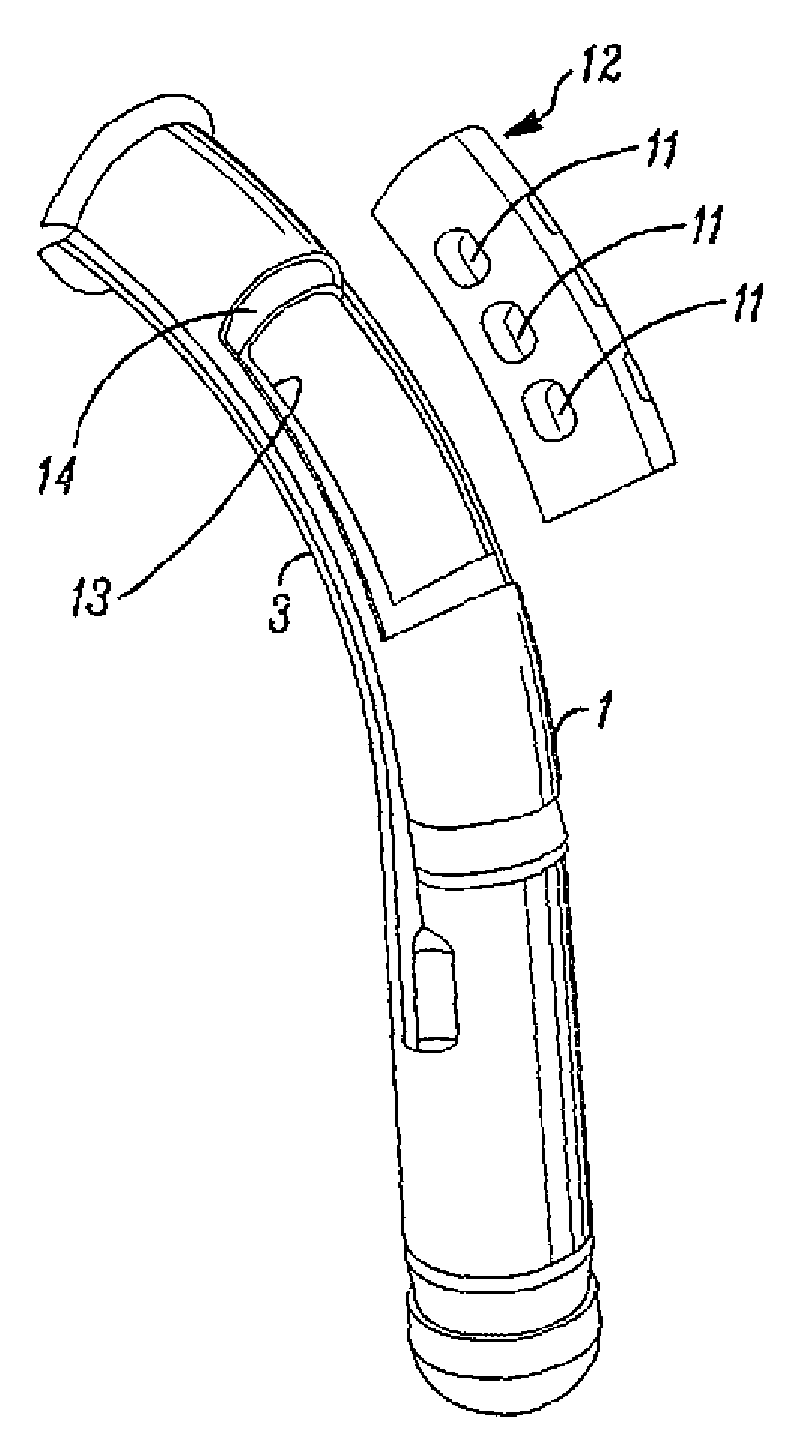

[0016] First refer to Figures 1 to 4 , a tracheostomy tube comprising a soft, flexible first material, typically silicone, and a molded shaft 1 of circular cross-section. The patient end region 2 of the cannula is straight and communicates with a curved intermediate region 3 which extends to a neck flange 4 and a conventional machine end coupling 5 . A seal in inflatable form of an envelope 15 (shown deflated) surrounds the patient end region 2 , the interior of the envelope in communication with the inflation line 6 extending along a slot 7 formed along one side of the shaft 1 . The inflation line extends through the neck flange 4 and is terminated at its machine end by a connector and an inflation indicator 8 . As described thus far, cannulation is conventional.

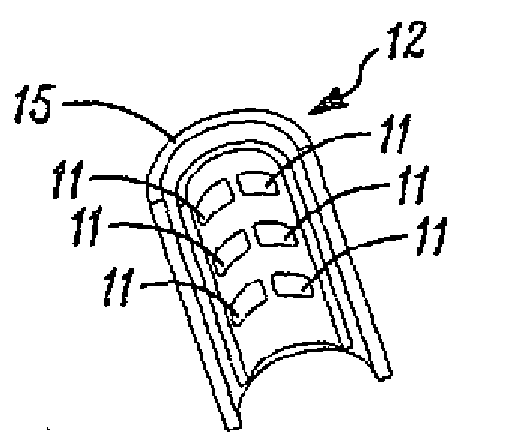

[0017] The cannula shaft 1 comprises a fenestrated area 10 formed substantially centrally along the curved area 3 at a position central to the tracheal airway 20 during use. The fenestrated area 10 has six open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com