Motor and method for manufacturing and/or driving motor

A technology for driving motors and generators, applied in the direction of DC motor speed/torque control, electric components, synchronous generators, etc., can solve problems such as reducing the life of ball bearings, achieve reliable use, fast potential balance, and minimize parasitic The effect of electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

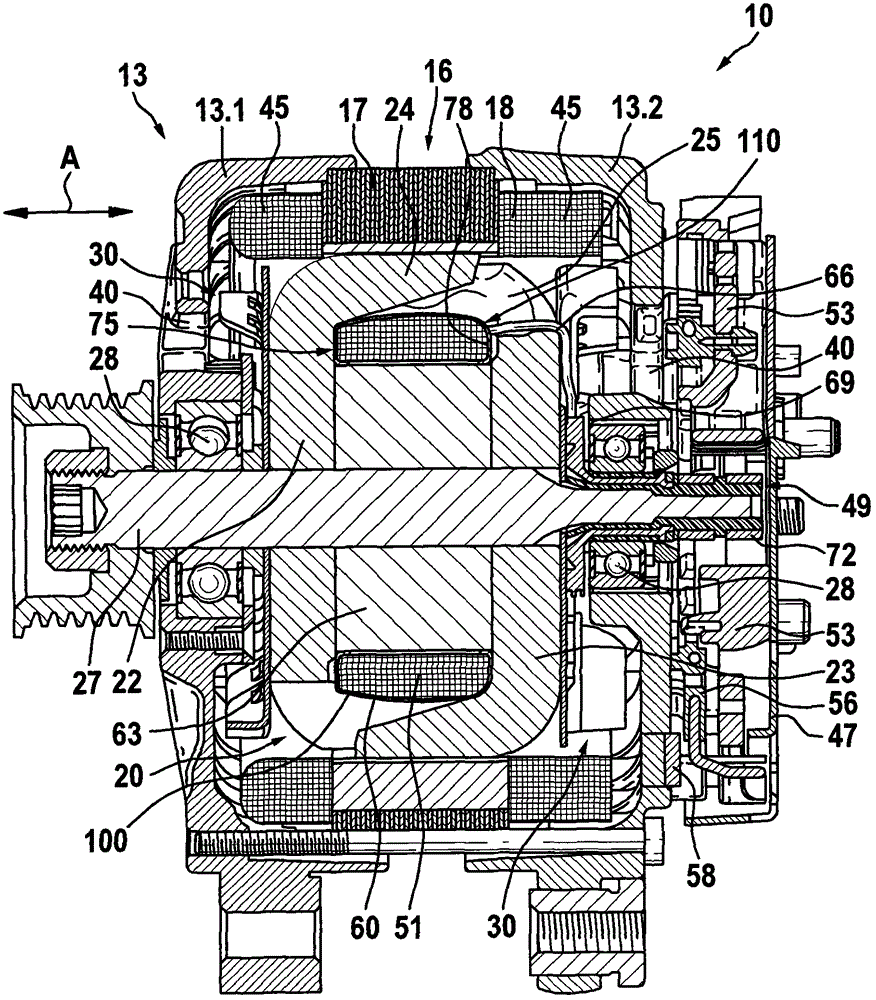

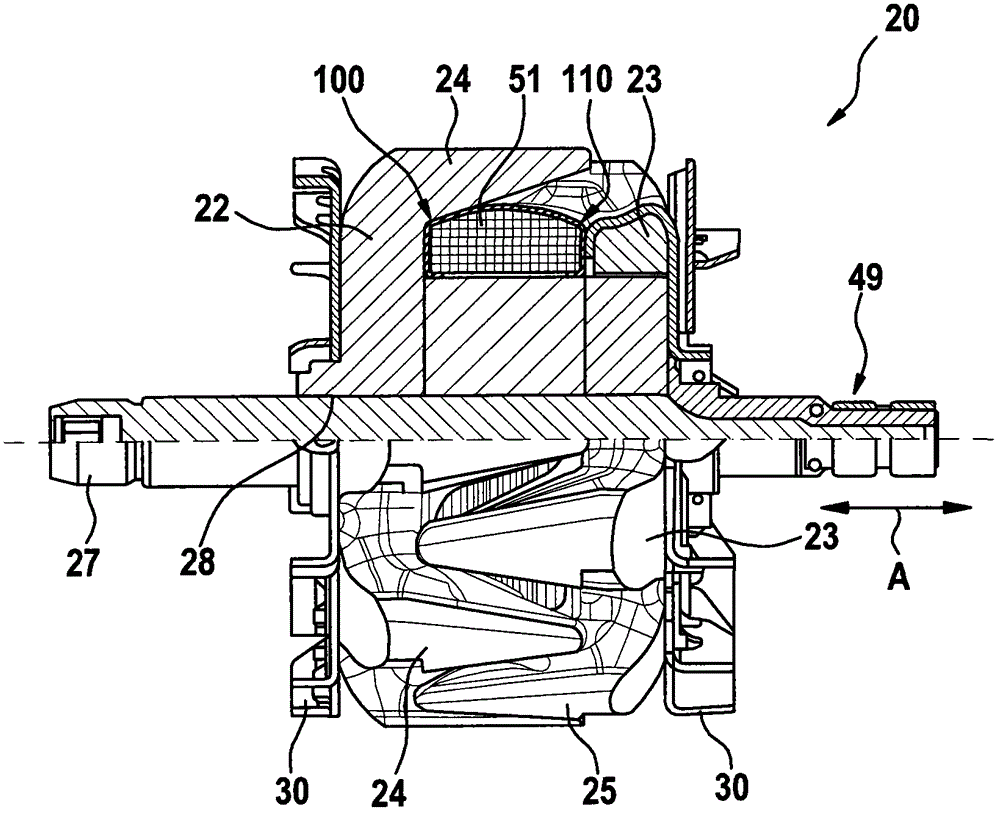

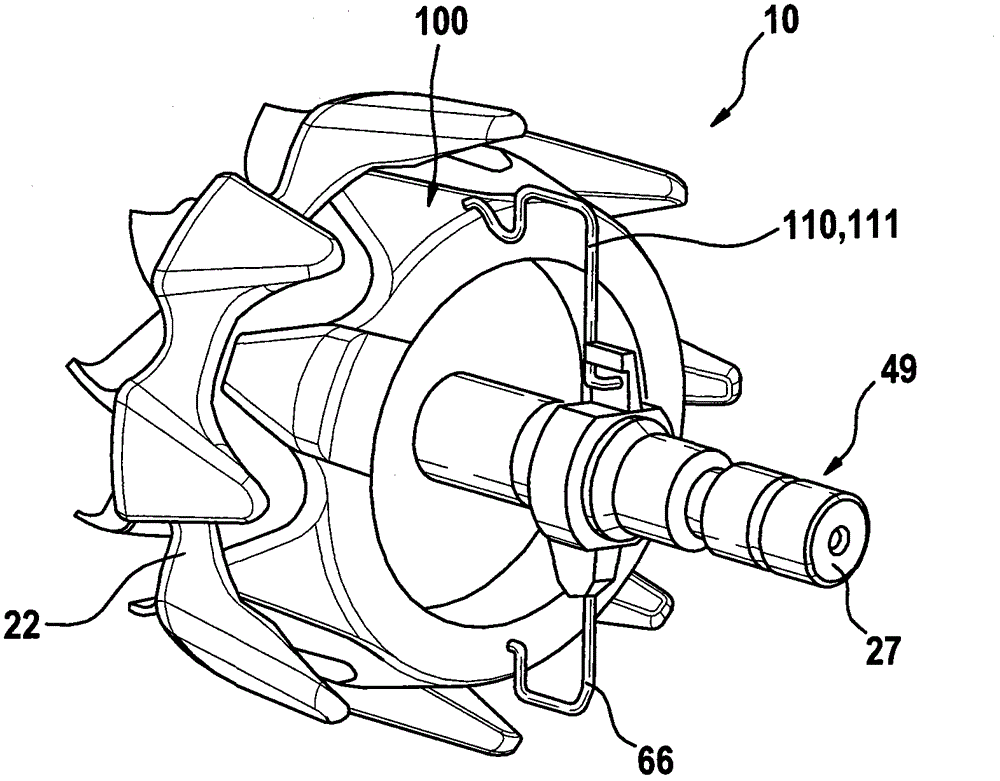

[0027] figure 1 An electric machine 10 designed as a claw-pole generator is shown in cross section, more precisely a cross section of an electric machine 10 which, in the embodiment shown here, is embodied as a motor vehicle for converting mechanical energy into electrical energy claw pole generator. The electric machine 10 has a two-part housing 13 comprising a first bearing shield 13.1 and a second bearing shield 13.2. The bearing caps 13.1, 13.2 themselves accommodate the so-called stator 16, which consists of a substantially circular stator core 17 and is inserted or embedded in its radially inwardly oriented, axially extending grooves ( prominent) stator winding 18. The annular stator 16 surrounds with its radially inwardly directed surface a rotor 20 , which is designed as a claw pole rotor (not shown in detail here). The rotor 20 includes claw poles 22 and counter poles 23 (see also figure 2 ), they are also called claw pole plates, and claw pole fingers 24 and 25 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com