Transport and mounting integration ammunition carrier

A bomb carrier and bomb trailer technology is applied in transportation and packaging, ground installations, and equipment for transporting goods. The effect of saving security expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The following examples are only used to illustrate the present invention, and are not intended to limit the protection scope of the present invention.

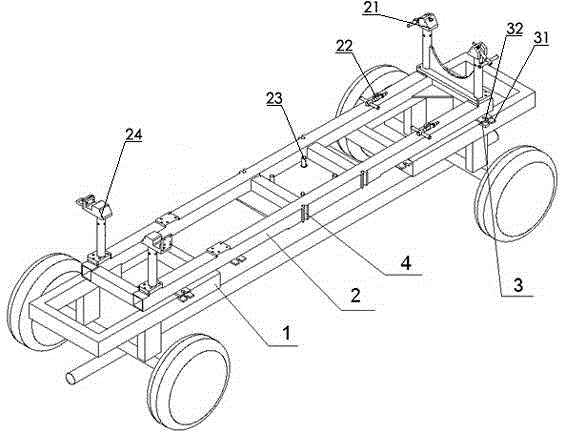

[0018] refer to figure 1 and figure 2 , the transport and mounting integrated bomb carrier of the present invention, it includes a car body 1, a movable bracket 2, a connecting device 3 and a quick release lock 4, and the car body 1 and the movable bracket 2 are quickly connected by the connecting device 3 , the quick release lock 4 is installed on the car body 1, and the quick release lock 4 is used for the connection between the movable bracket 2 and the pallet of the bomb vehicle;

[0019] refer to figure 1 , when the missile is transported, the movable bracket 2 is connected to the vehicle body 1 of the bomb carrier;

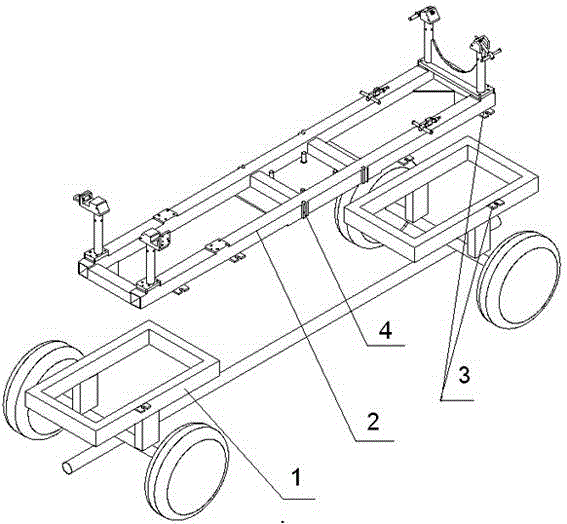

[0020] refer to figure 2 , when the missile is mounted, the connect...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap