A low-temperature container with a weighable liner

A low-temperature container and liner technology, which is applied in the field of metrology and testing, can solve problems such as inability to eliminate or quantify compensation, and achieve the effect of improving accuracy utilization and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and examples.

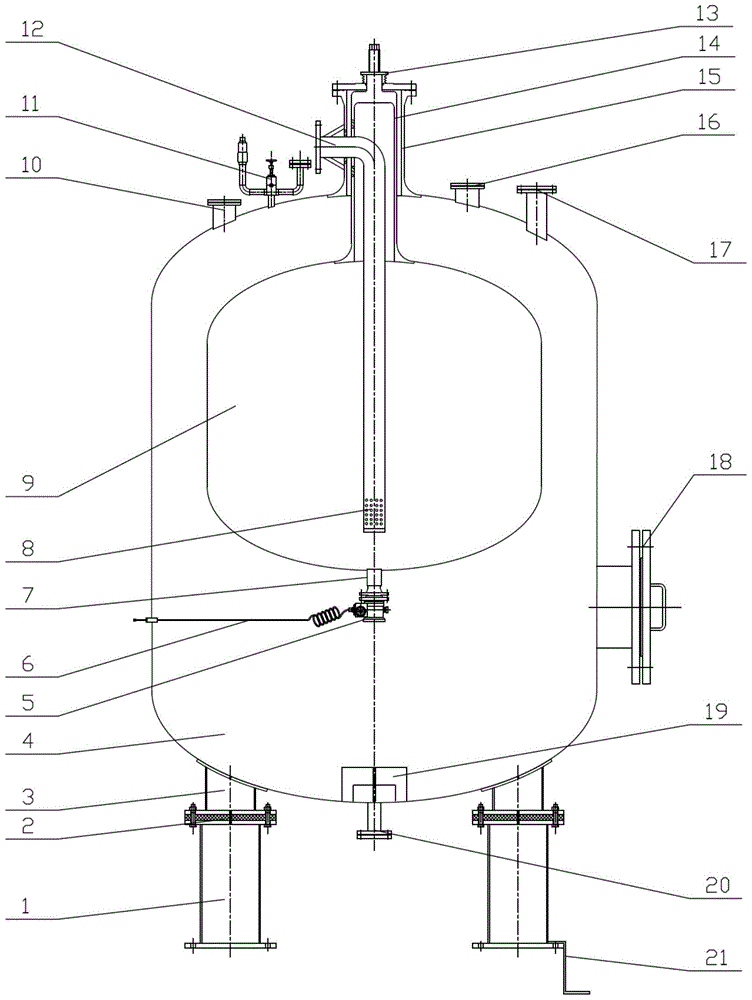

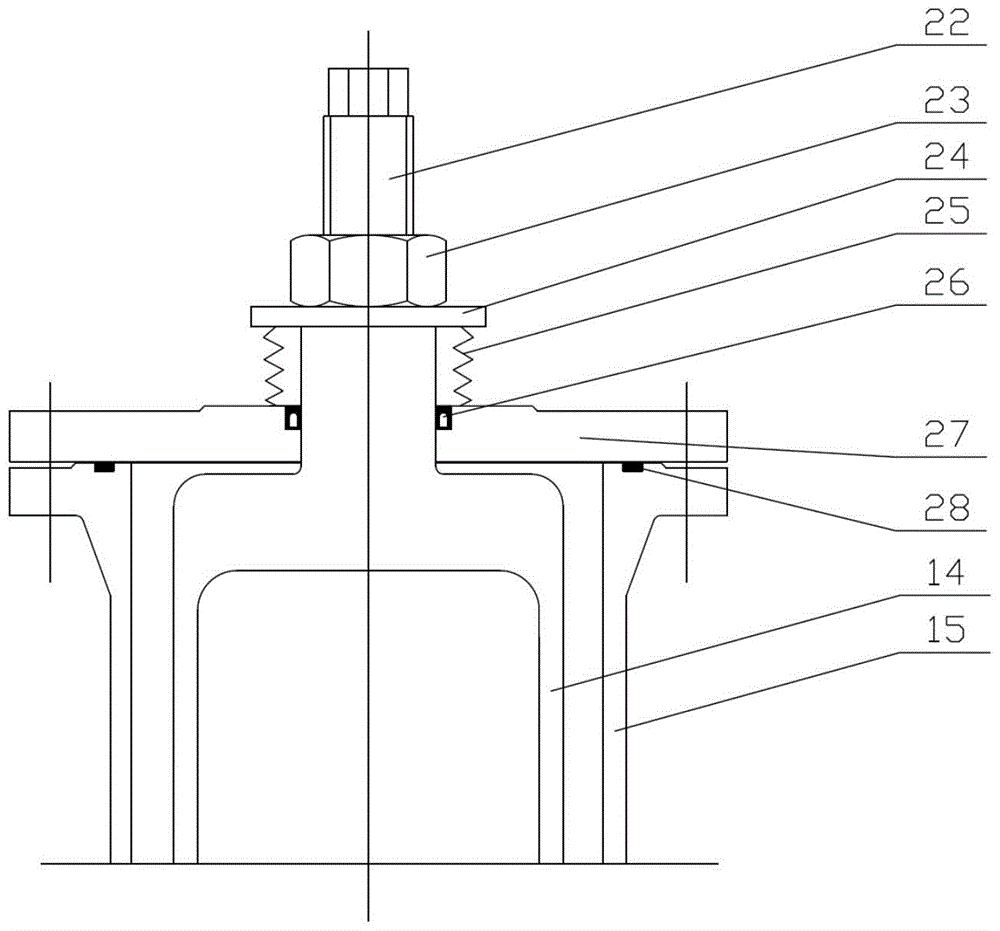

[0028] as attached figure 1 As shown, the present invention provides a cryogenic container with a weighing inner tank, comprising an outer tank, a weighing inner tank, a liquid inlet pipe 12, a buffer 8, a neck sealing assembly 13, a bottom valve 5 and a bottom valve control gas Line 6;

[0029] The outer tank includes an outer tank body 4, a container leg, an anti-vortex plate 19, an electrostatic grounding plate 21, an outer tank neck pipe 15, and a tank in which both ends of the outer tank body 4 are spherical and the middle section is cylindrical body, one end of the outer tank neck tube 15 is welded to the center of the outer tank body 4 upper end, so that the outer tank body 4 communicates with the inner cavity of the outer tank neck tube 15, and the other end of the outer tank neck tube 15 It is a flange structure, the center line of the outer tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com