rocker arm

A main body and valve technology, applied in the field of rocker arm, can solve complex and expensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

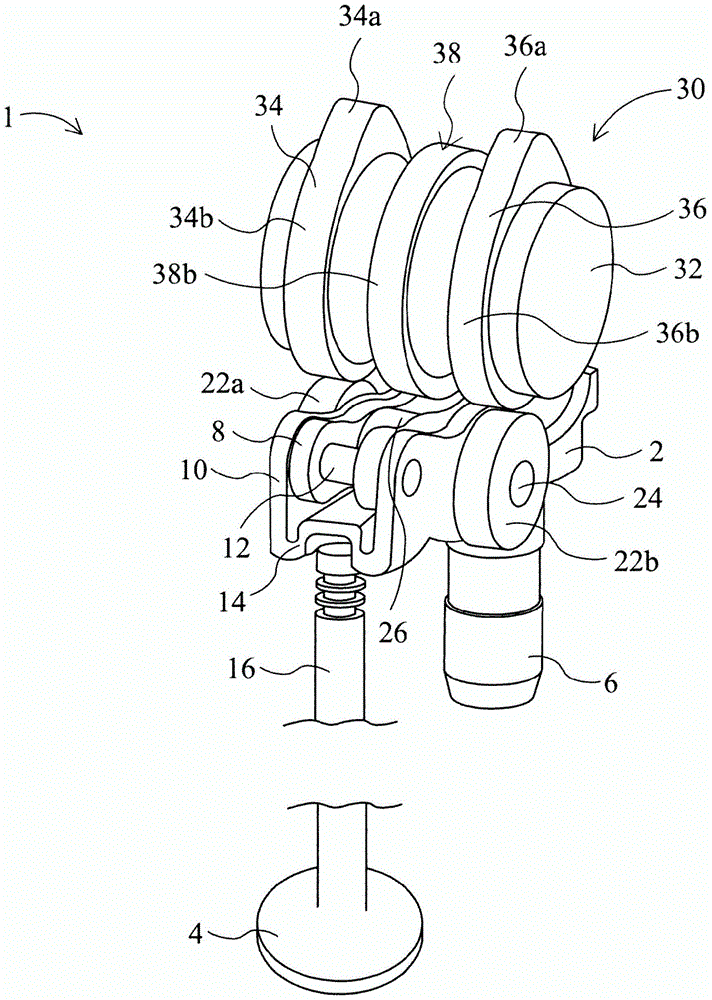

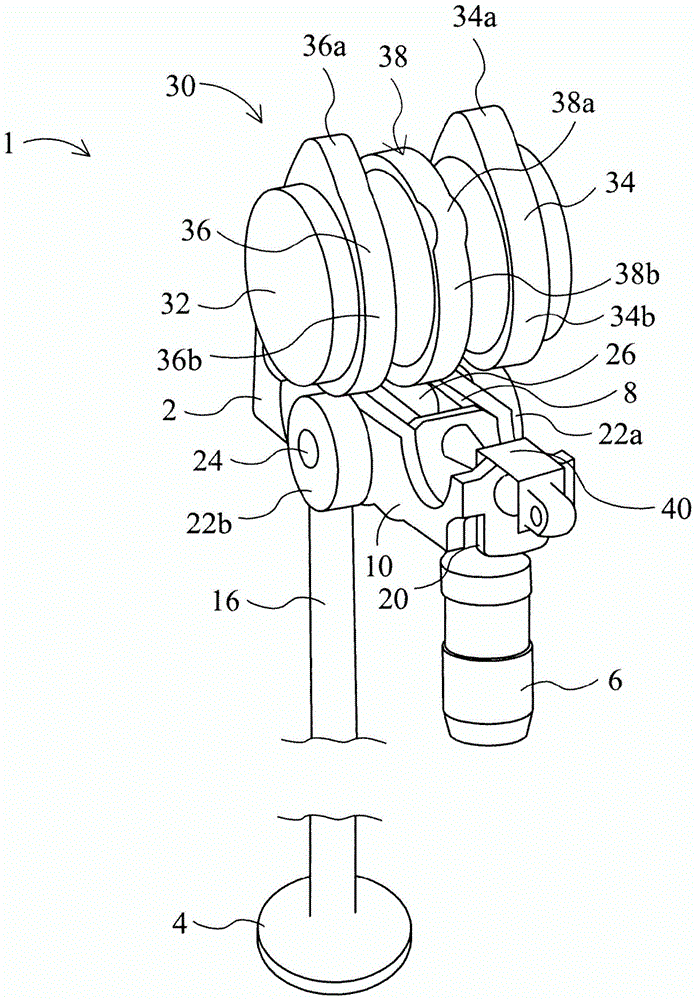

[0016] see first figure 1 and figure 2 , the valve train assembly 1 includes a double-lift rocker arm 2 , an engine valve 4 for an internal combustion engine cylinder (not shown), and a lash adjuster 6 . The rocker arm 2 comprises an inner body or arm 8 and an outer body or arm 10 . The inner body 8 is pivotally mounted on an axle 12 for connecting the inner body 8 and the outer body 10 . The first end 14 of the outer body 10 engages the valve stem 16 of the valve 4, and the second end 20 of the outer body 10 is mounted for pivotal movement on the lash adjuster 6, which is supported on the engine block (not shown). )middle. The lash adjuster 6 can be, for example, a hydraulic lash adjuster, and is used to adjust the clearance between various components in the valve train assembly 1 . Lash adjusters are known per se, so the lash adjuster 6 will not be described in detail.

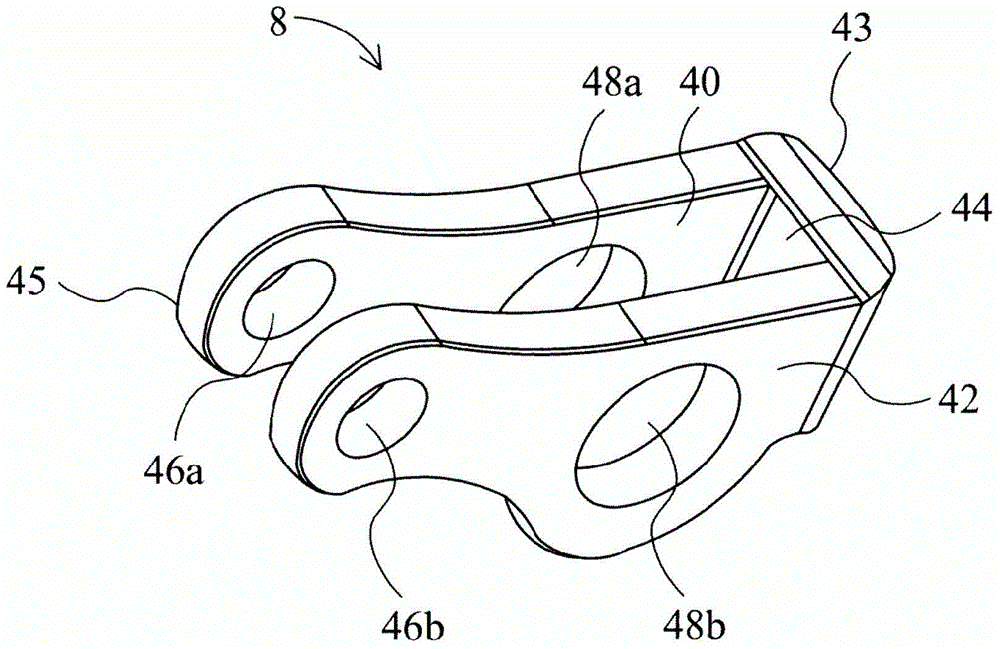

[0017] The rocker arm 2 is provided with a pair of main lift rollers 22a and 22b rotatably mounted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com