A preparation method and device for foam cement slurry and its application

A preparation method and cement slurry technology are used in the control of the mixing ratio of foam and cement slurry, and in the field of preparation of foamed cement slurry, which can solve the problems that the proportion of foam and cement slurry cannot be controlled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

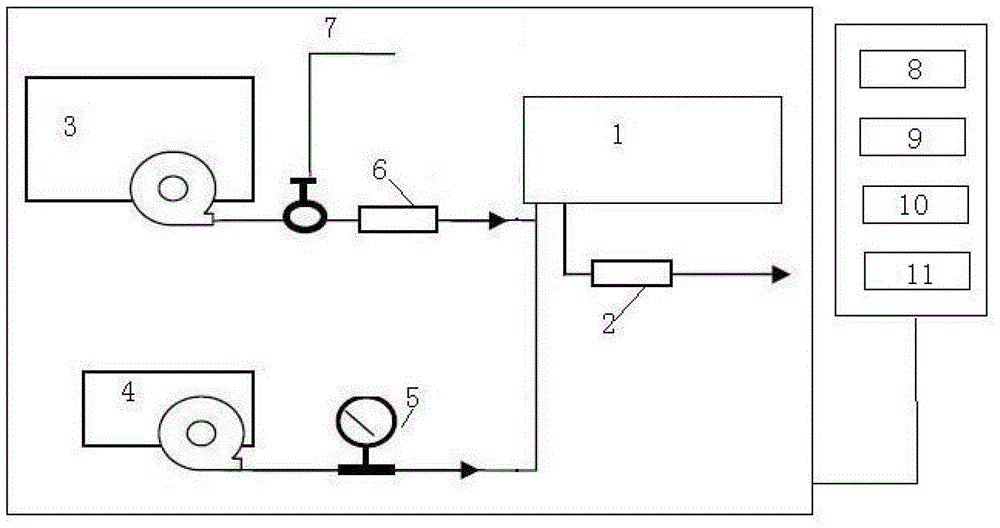

Method used

Image

Examples

Embodiment 1

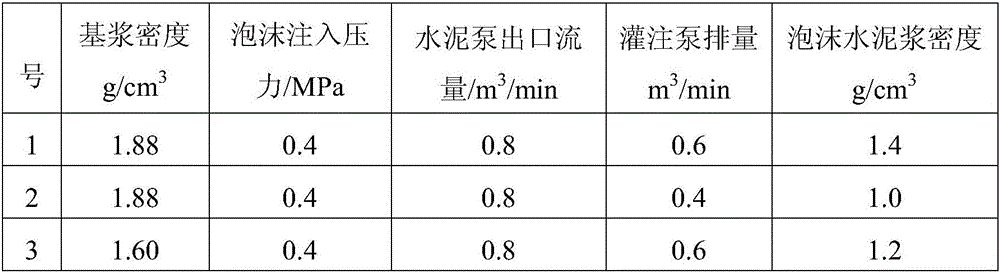

[0078] In the construction of foam cementing on site, according to the needs of the site operation, the foam cement slurry density ρ 1 The target foam cement slurry density ρ set by the setting and detection module 11 1 1.4g / cm 3 .

[0079] In order to have a foamed grout with the above target density, first pass the grout density ρ 2 Detection module 10 measures cement-based slurry density 1.88g / cm 3 , to control the foam injection pressure P 0 =0.4MPa, through the first flow F 1 The control module 8 pre-sets the first flow rate F of the foam cement slurry equipment outlet 1 =0.8m 3 / min, through the second flow F 2 Control module 9 passes formula I::ρ 1 = ρ 2 *F 2 / F 1 Calculate and adjust the second flow rate F 2 =0.6m 3 / min; the target foam cement slurry density is 1.4g / cm 3 .

Embodiment 2

[0081] In the construction of foam cementing on site, according to the needs of the site operation, the foam cement slurry density ρ 1 The target foam cement slurry density ρ set by the setting and detection module 11 1 1.0g / cm 3 .

[0082] In order to have a foamed grout with the above target density, first pass the grout density ρ 2 Detection module 10 measures cement-based slurry density 1.88g / cm 3 , to control the foam injection pressure P 0 =0.4MPa, through the first flow F 1 The control module 8 pre-sets the first flow rate F of the foam cement slurry equipment outlet 1 =0.8m 3 / min, through the second flow F 2 Control module 9 passes formula I::ρ 1 = ρ 2 *F 2 / F 1 Calculate and adjust the second flow rate F 2 =0.4m 3 / min; that is, the target foam cement slurry density is 1.0g / cm 3 .

Embodiment 3

[0084] In the construction of foam cementing on site, according to the needs of the site operation, the foam cement slurry density ρ 1 The target foam cement slurry density ρ set by the setting and detection module 11 1 1.2g / cm 3 .

[0085] In order to have a foamed grout with the above target density, first pass the grout density ρ 2 Detection module 10 measures cement-based slurry density 1.6g / cm 3 , to control the foam injection pressure P 0 =0.4MPa, through the first flow F 1 8 control modules pre-set the first flow F of the foam cement slurry equipment outlet 1 =0.8m 3 / min, through the second flow F 2 Control module 9 passes formula I::ρ 1 = ρ 2 *F 2 / F 1 Calculate and adjust the second flow rate F 2 =0.6m 3 / min; that is, the target foam cement slurry density is 1.2g / cm 3 .

[0086] Table 1

[0087]

[0088] Through this inventive method, the displacement of the filling pump can be adjusted by stabilizing the outlet displacement of the cement pump. Wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com