Hopper of automatic feeding machine

A feeder and hopper technology, applied in the equipment field of poultry farms, can solve the problems of feed easily blocking the hopper, uneven feeding of the hopper, non-detachable connection between the hopper and the discharge pipe, etc., achieving simple structure and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

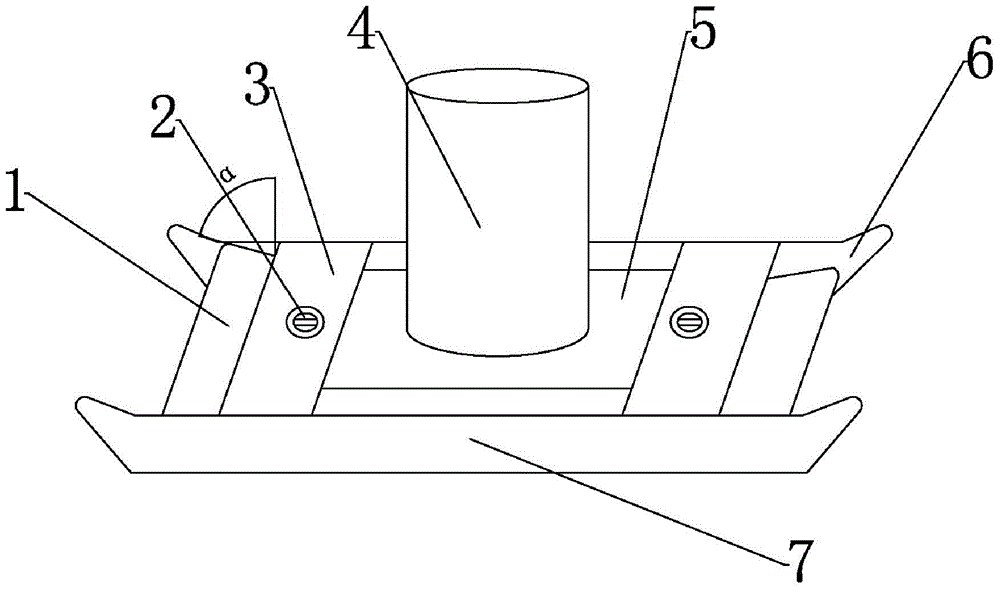

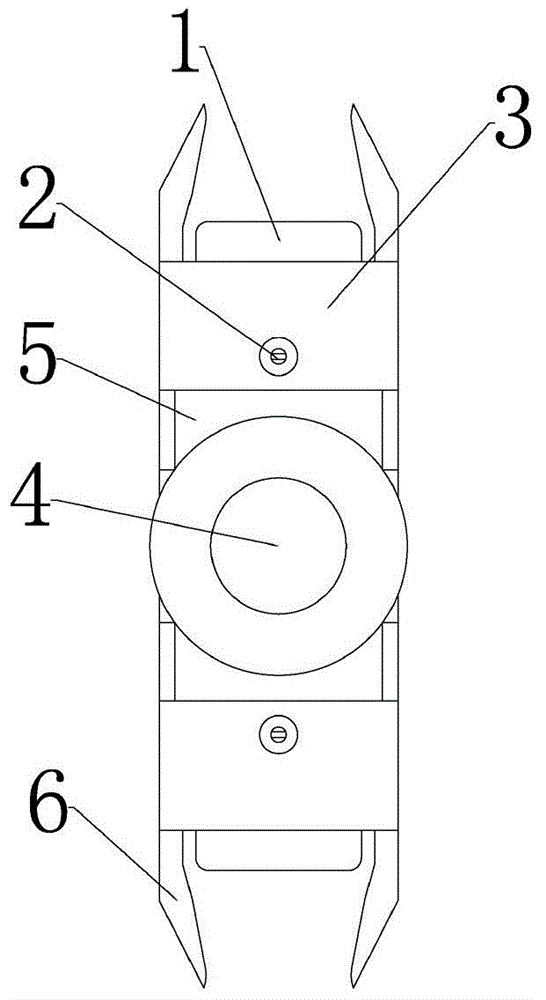

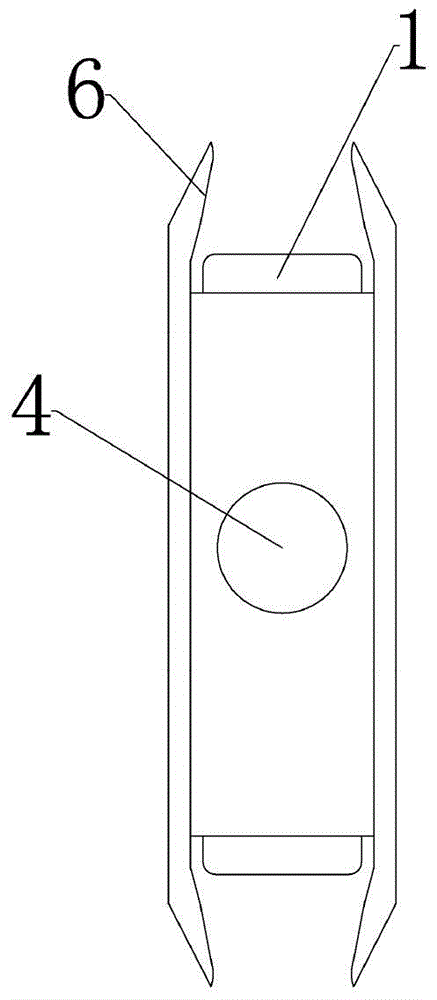

[0015] Such as Figure 1 to Figure 3 As shown, a hopper of an automatic feeding machine includes an arc-shaped plate 1, an adjustment button 2, a pressing plate 3, a feed port 4, a guide groove 5, a guide plate 6 and a hopper main body 7, and the lower surface of the hopper main body 7 is Both ends are provided with arc-shaped plates 1 respectively, and the arc-shaped plates 1 are integrated with the lower surface of the hopper main body 7, and the arc-shaped plates 1 form an angle α upward with the lower surface of the hopper main body 7, and the two sides of the arc-shaped plates 1 Guide plates 6 are respectively provided, and the middle part of the hopper main body 7 is provided with a feed port 4, and the feed port 4 is vertically communicated with the hopper main body 7, and pressure plates 3 are respectively arranged on both sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com