Preparation method and device of high-double-refraction rotary optical fiber

A rotating optical fiber, high birefringence technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problem that high birefringence rotating optical fiber cannot be rotated and drawn at high speed, etc., to achieve the effect of high integration, easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

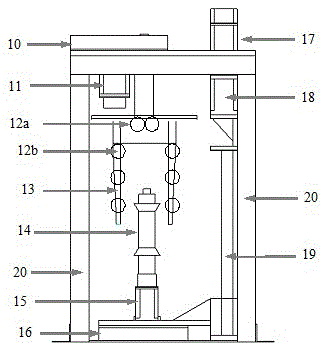

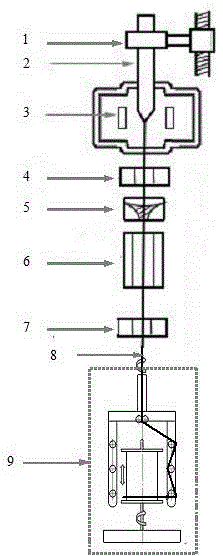

[0021] High birefringence spun optical fiber preparation method such as figure 1 As shown, the specific method is to clamp the preform (2) on the rod feeding device (1), send the preform to the hot zone position in the drawing furnace (3), and when the preform is heated to a molten state, the optical fiber ( 8) Pass through the wire diameter meter A (4), the coating cup (5), the curing device (6), and the wire diameter meter B (7) to enter the rotating wire collection device (9), and the direction of the optical fiber (8) is shown in the figure As shown, it first passes through the guide wheel (12a), then passes through three guide wheels from the side in an "S" shape, and is finally fixed on the winding drum; start the winding drum (14) and the fly fork (13) successively, and the optical fiber The traction is formed by the rotational speed difference between the fly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com