Multi-station jacking mold

A multi-station, ejecting technology, used in manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problem of inability to meet product process requirements, inability to eject material from the core, and no good solutions, etc. problems, to achieve the effect of convenient fastening, reliable reset action, and good anti-eccentric load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

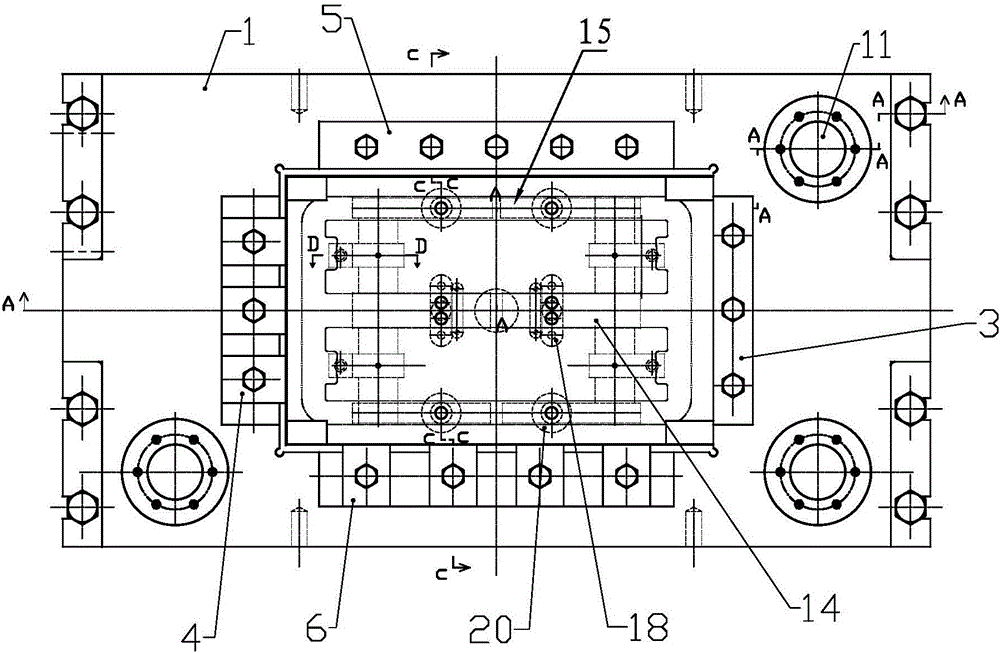

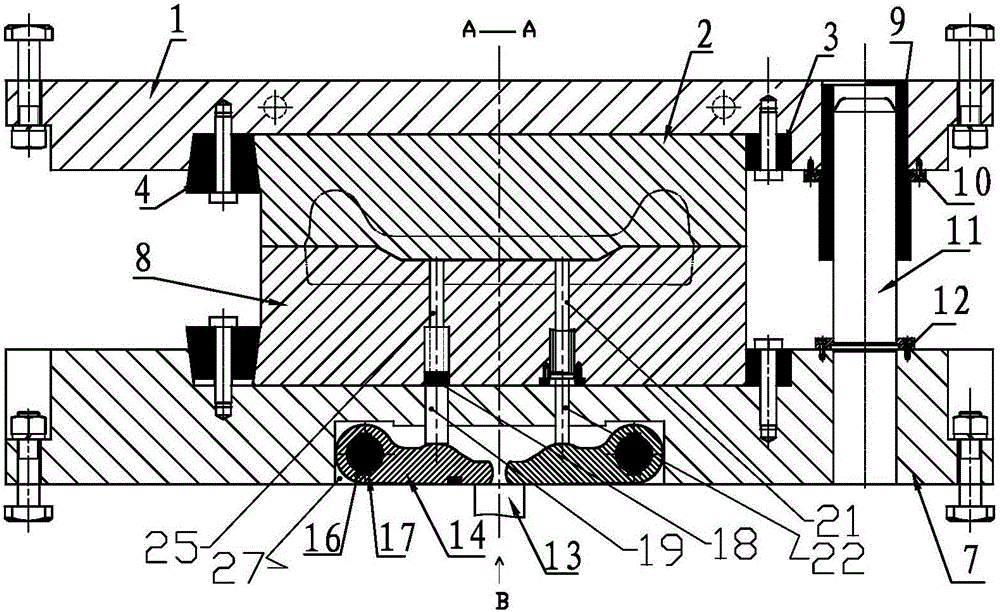

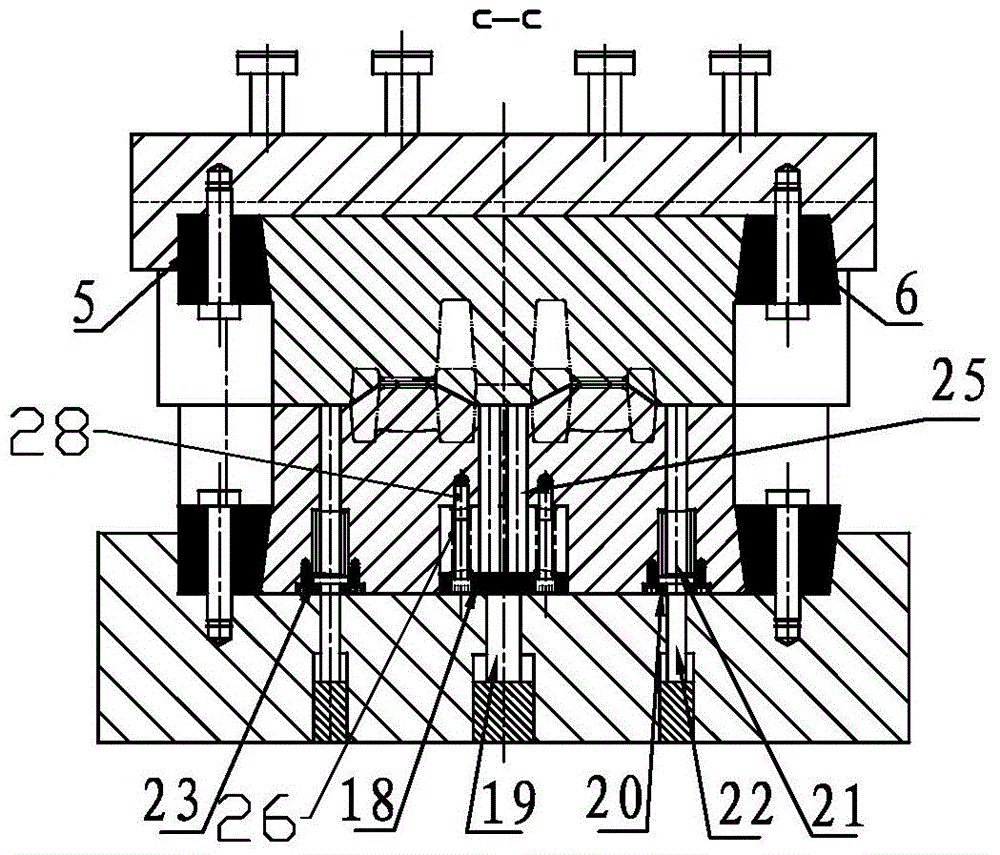

[0026] Refer to the attached figure 1 to attach Figure 12 The multi-station ejector mold of the present invention will be described in detail below.

[0027] The multi-station jacking mold of the present invention, its structure comprises upper mold 2, lower mold 8, upper mold base 1 and lower mold base 7, described upper mold 2 is arranged on the bottom of upper mold base 1, and with it connected, the lower mold 2 is arranged on the upper part of the lower mold base 7 and is connected with it, the upper mold 2 is arranged on the upper part of the lower mold 8, and the lower part of the cavity of the lower mold 8 and the lower mold base 7 are provided with ejector material mechanism, the ejector mechanism includes a middle ejector rod, a side ejector rod, a middle swing arm 14, a side swing arm 15, a swing arm shaft 16 and an equipment ejector rod 13, and the lower middle position of the lower mold base 7 is provided with The swing arm cavity 27, the swing arm shaft 16 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com