Assembled building wall panel components

It is an assembled and veneered technology, which can be used in building construction, construction, covering/lining, etc. It can solve the problems of large usage, increase the overall construction cost, low work efficiency, etc., and achieve diversified choices and beautiful wall products. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

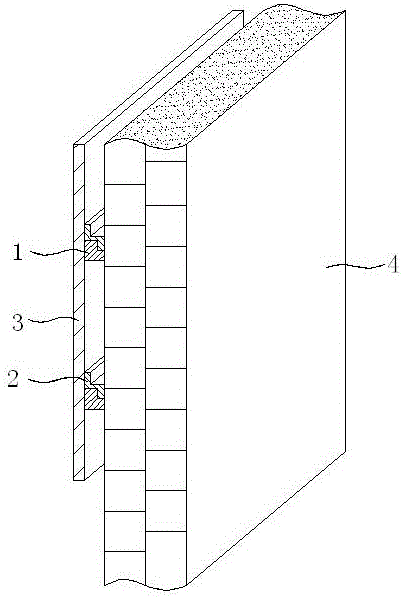

[0013] Assembled building wall panel member of the present invention is to be fixed on wall 4 by keel 1, hanging beam 2 and wall panel 3, as figure 1 As shown, on the wall 4, more than one keel 1 is fixedly arranged at parallel intervals, and at least one hanging beam 2 is fixed on the back side of the wall panel 3, and the hanging beam 2 is occludedly connected with the keel 1, that is, on the keel 1 There is a buckle I, and the hanging beam 2 is provided with a buckle II that fits with the buckle I.

[0014] There are two types of buckle engagement methods, namely:

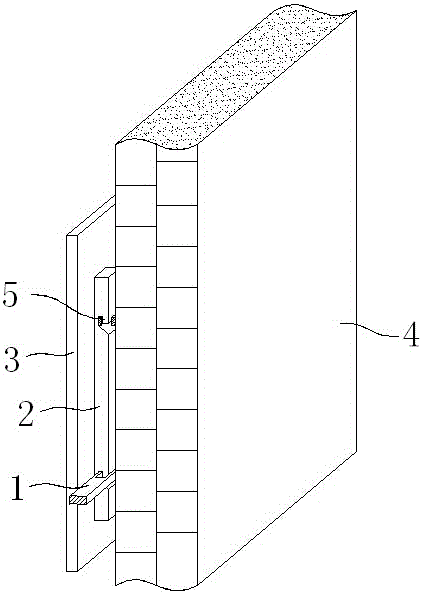

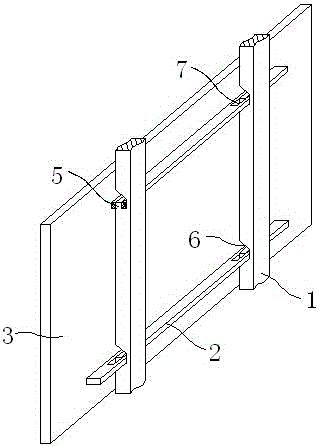

[0015] 1) if figure 2 , the keel 1 is vertically fixed on the wall, and the hanging beam 2 is perpendicular to the keel. The buckle I on the keel 1 is a right-angled trapezoidal groove 6 with a rib 5, and the buckle II on the hanging beam 2 is a hollowed-out rectangular hole 7, which is adapted to the rib 5 . The wall veneer 3 is fixed on the wall 4 through the keel 1 and the hanging beam 2, and the multi-...

Embodiment 2

[0018] Assembled building wall panel member of the present invention is to be fixed on wall 4 by keel 1, hanging beam 2 and wall panel 3, as Figure 4 As shown, the keel 1 is fixedly arranged on the wall at intervals in parallel. The keel 1 is L-shaped and can be made of angle steel. 2. There are reverse extension ends on both sides of the main body. One reverse extension end is engaged with the groove formed by the keel 1 and the wall 4. The other reverse extension end is fixed to the wall panel 3 and the hanging beam 2 Can also be angle steel. The wall panel 3 is fixed on the wall 4 by snapping into the groove between the keel 1 and the wall 4 through the hanging beam 2, and the multi-face wall panel 3 is expanded to form a wall

[0019] In order to ensure the accuracy and beauty of the installation, the buckle Ⅰ on the keel 1 and the buckle Ⅱ on the hanging beam 2 should be located on the same straight line.

[0020] In order to make the wall panel 3 beautiful, various ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com