Installing structure of jacquard needles in jacquard

A technology of installation structure and jacquard needle, applied in the direction of jacquard machine, textile, textile and paper making, etc., can solve problems such as large up and down swing amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

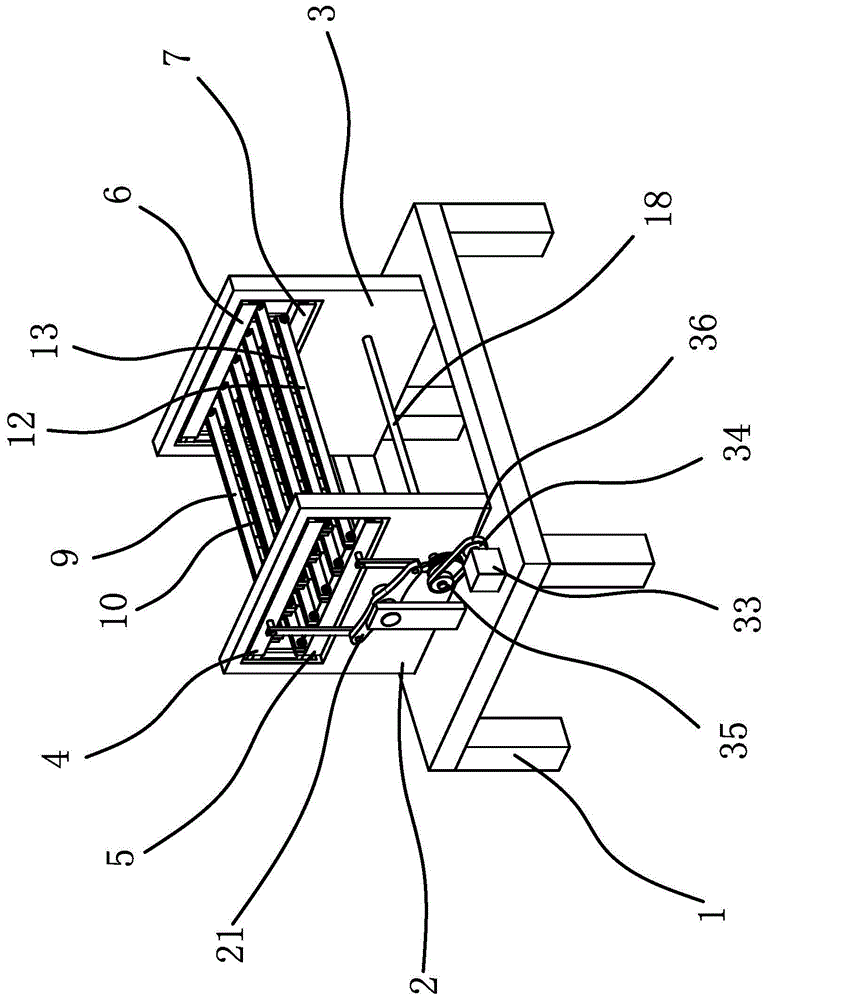

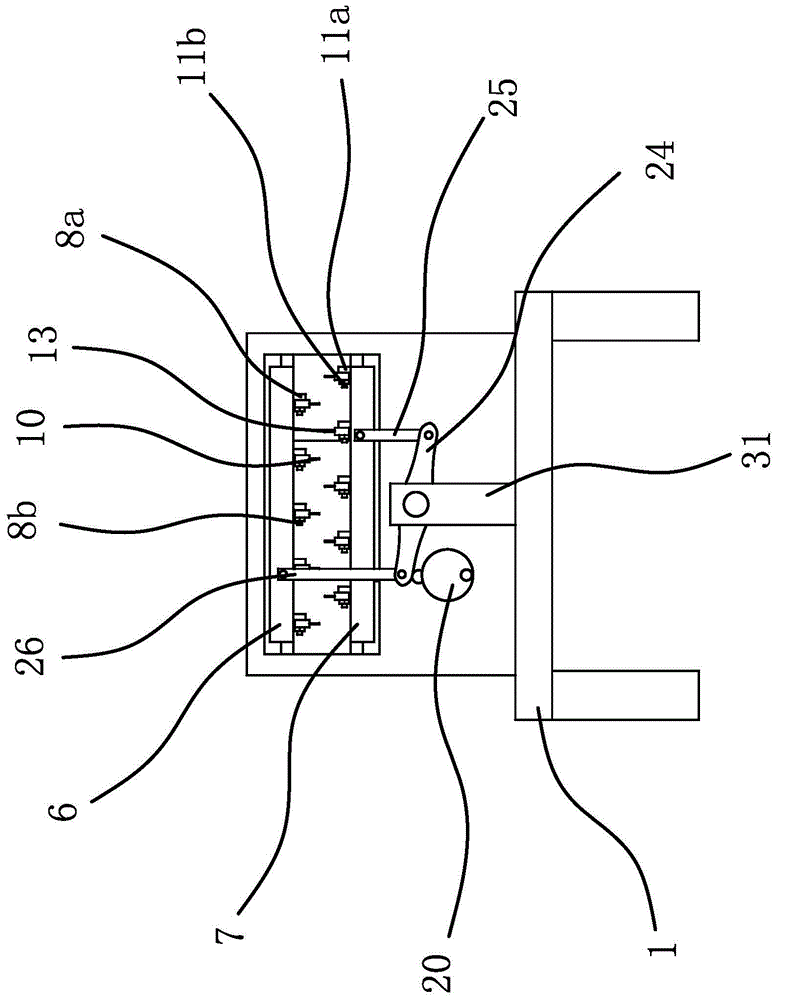

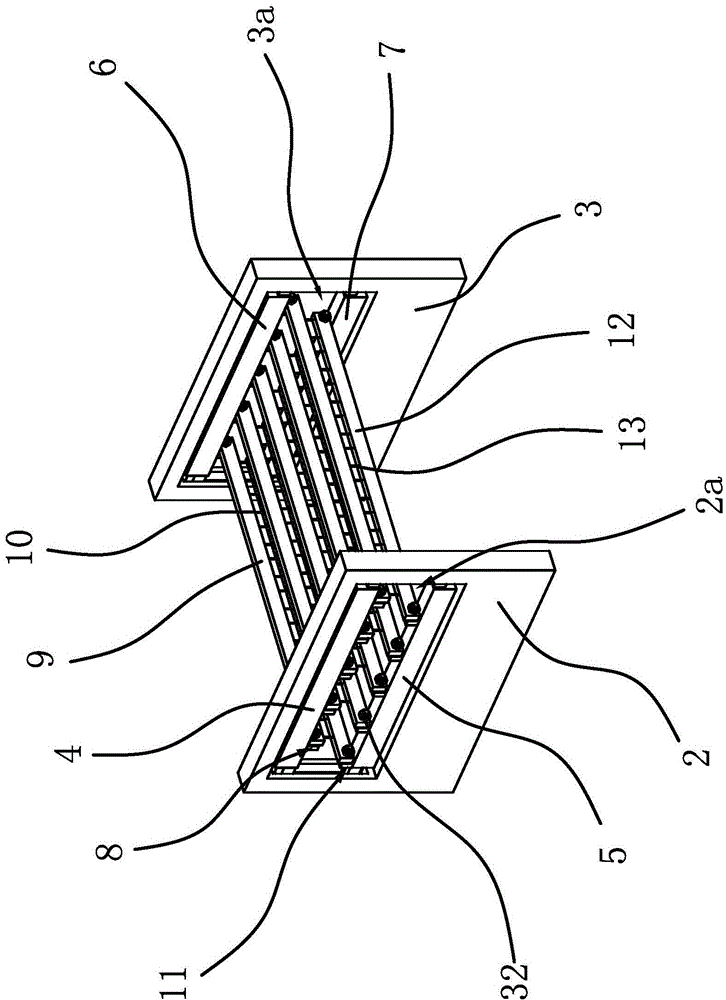

[0022] Such as figure 1 and figure 2 Shown, a kind of jacquard machine comprises frame 1 and left support plate 2 and right support plate 3 that are vertically symmetrically fixed on frame 1 two ends, and left support plate 2 and right support plate 3 are fixed on machine by bolt nut 32 1, so as to facilitate the loading and unloading of the left support plate 2 and the right support plate 3. The left support plate 2 is provided with a rectangular through hole 2a, and the upper left knife rest 4 and the lower left knife rest 5 distributed up and down are arranged in the through hole one 2a, and the upper left knife rest 4 and the lower left knife rest 5 It can slide along the vertical direction of the left support plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com