Non-repeated support continuous support advanced hydraulic support

A hydraulic support and support advanced technology, applied in the direction of mine roof support, mining equipment, earthwork drilling, etc., can solve the problems of roof damage, unsuitable roof, low efficiency, etc., to avoid the effect of repeated support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

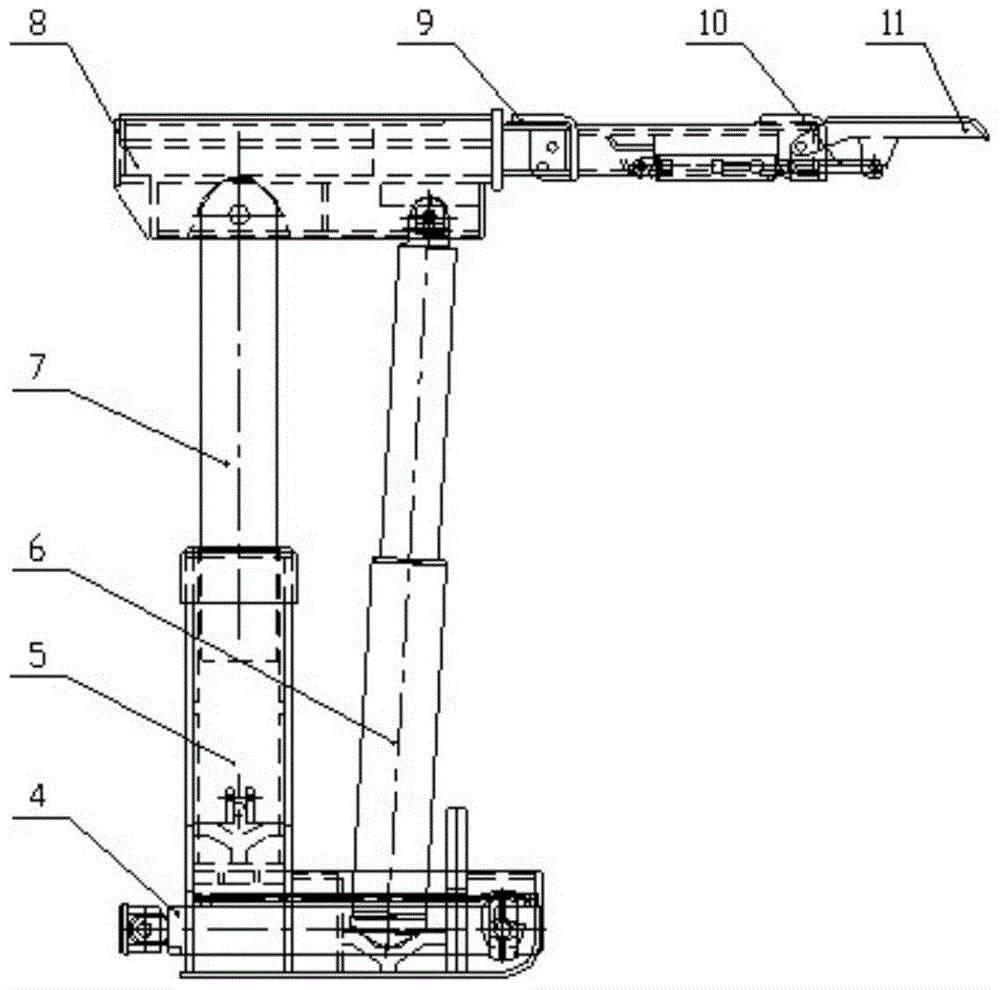

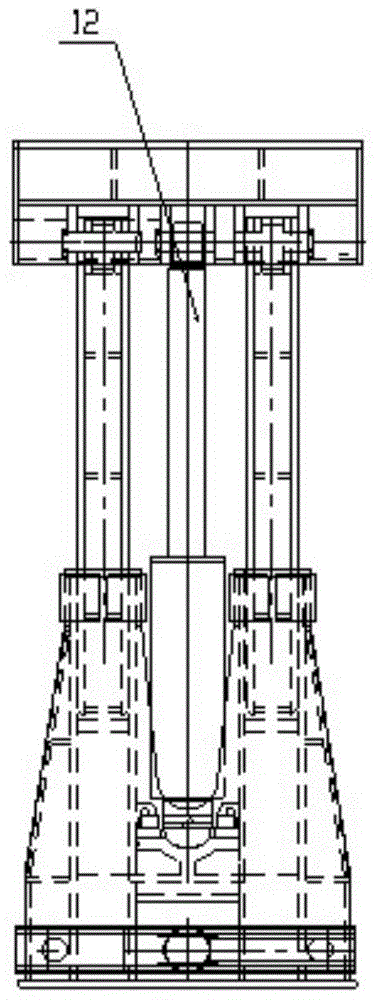

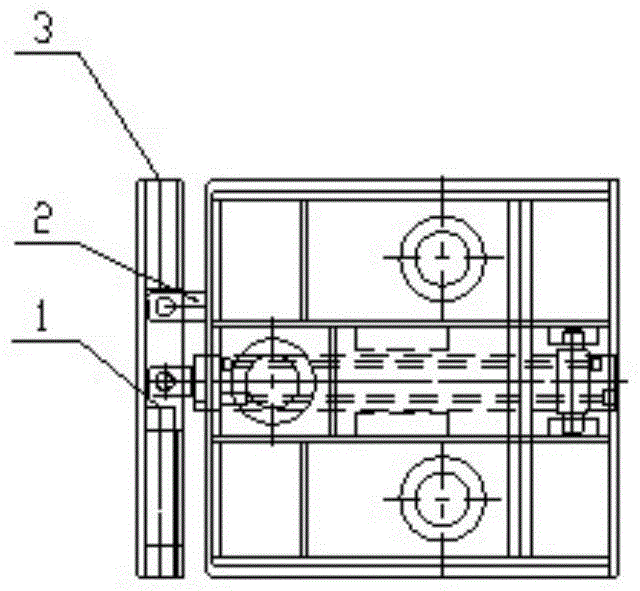

[0029] Such as Figure 1a , Figure 1b , Figure 1c As shown, it includes rotation lock pin 1, push beam fixed ear seat 2, push beam 3, push jack 4, base 5, column 6, telescopic rod 7, top beam 8, telescopic beam 9, side protection jack 10, side protection 11 , Balance jack 12.

[0030] The structural form is a telescopic rod-type stabilizing mechanism, a large balance jack, and a new type of two-column cover-type advanced hydraulic support without cover beams. The bracket has no movable side guards, long telescopic beams, and small side guard structures. Large support area, light weight, small transport size.

[0031] Such as figure 2 As shown, the top beam is a double-layer structure, the upper layer is a telescopic beam box, the lower layer is a column socket and box structure, and the telescopic beam jack and the side protection jack are placed in the middle layer.

[0032] The telescopic beam is in the form of a large beam head, and the installation position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com