Electronic measuring and weighing unit of checkweigher

A technology of electronic weighing scale and checkweigher, which is applied in the direction of continuous material flow weighing equipment, weighing, measuring device, etc., to achieve high resolution, eliminate the interference of weighing data, and reduce additional weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

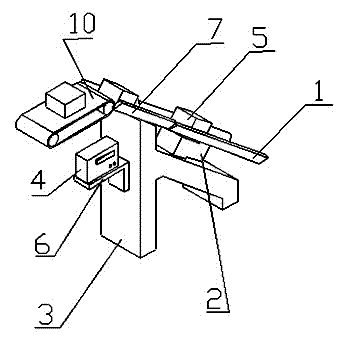

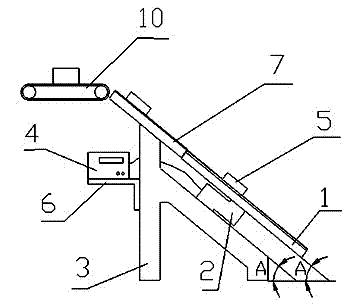

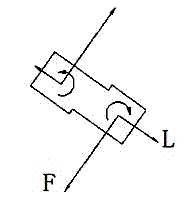

[0031] Such as Figure 1-2 As shown, an electronic measurement and weighing unit of a checkweigher, it includes a support frame 3 and at least one load cell 2 fixedly arranged on the support frame 3, and a weighing slideway 1 is fixedly arranged on the load cell 2 , the length direction of the weighing slideway 1 is at an angle A with the horizontal plane, 0°<A<90°; The length direction of the slideway 1 is vertical; when the load cell 2 is a rectangular load cell, it must be satisfied that the gravity does not generate a force component in the normal direction of the side of the load cell 2 . A weighing control instrument 4 electrically connected to the load cell 2 is also provided. The weighing slideway 1 is a rigid body made of hard wear-resistant material, which is in the form of a concave groove or a plane or a bobbin-shaped structure with openings at both ends. For example, the weighing slideway 1 can be a tank structure of stainless steel bent and then processed to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com