Patents

Literature

49results about How to "Reduce frictional energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

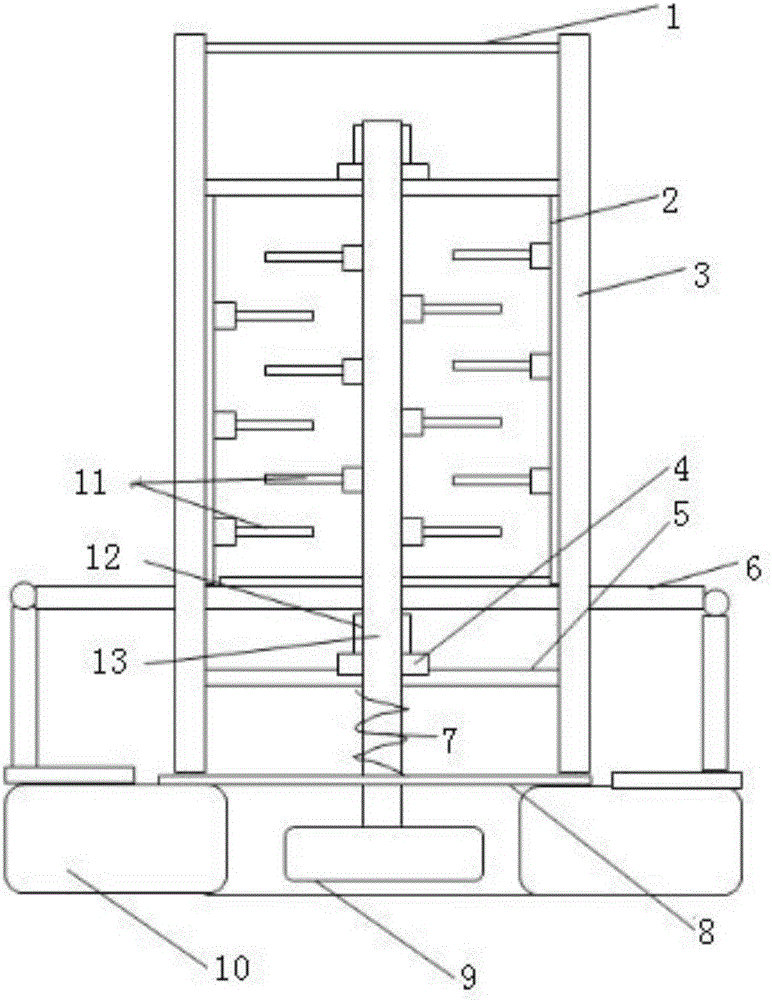

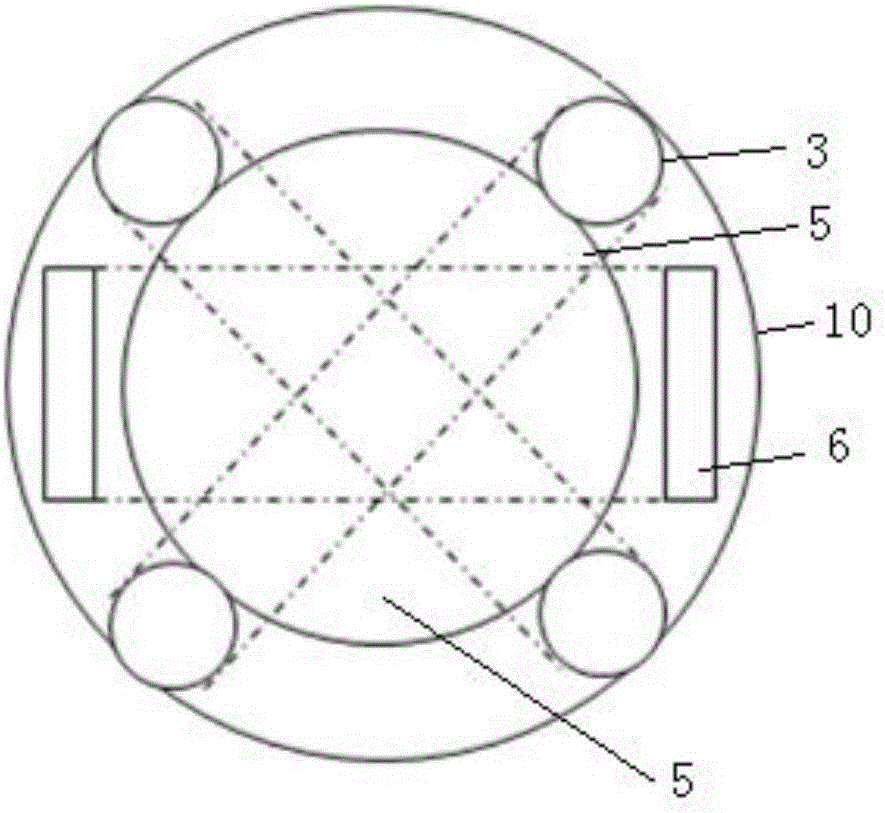

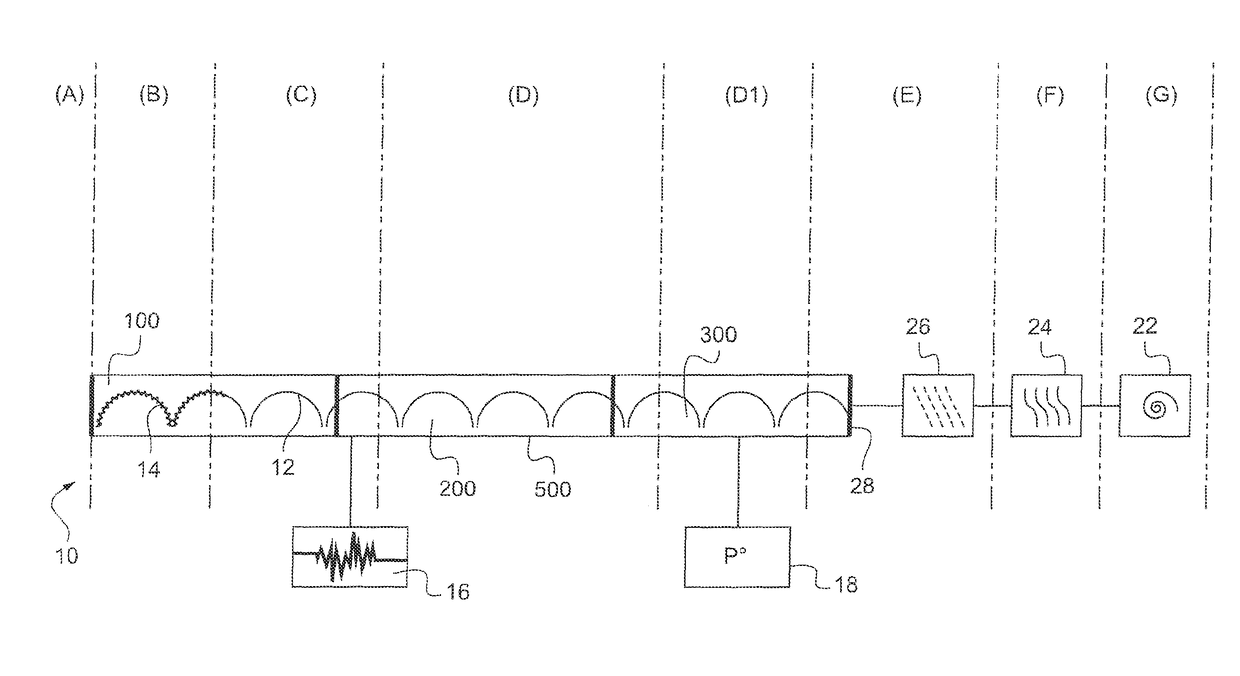

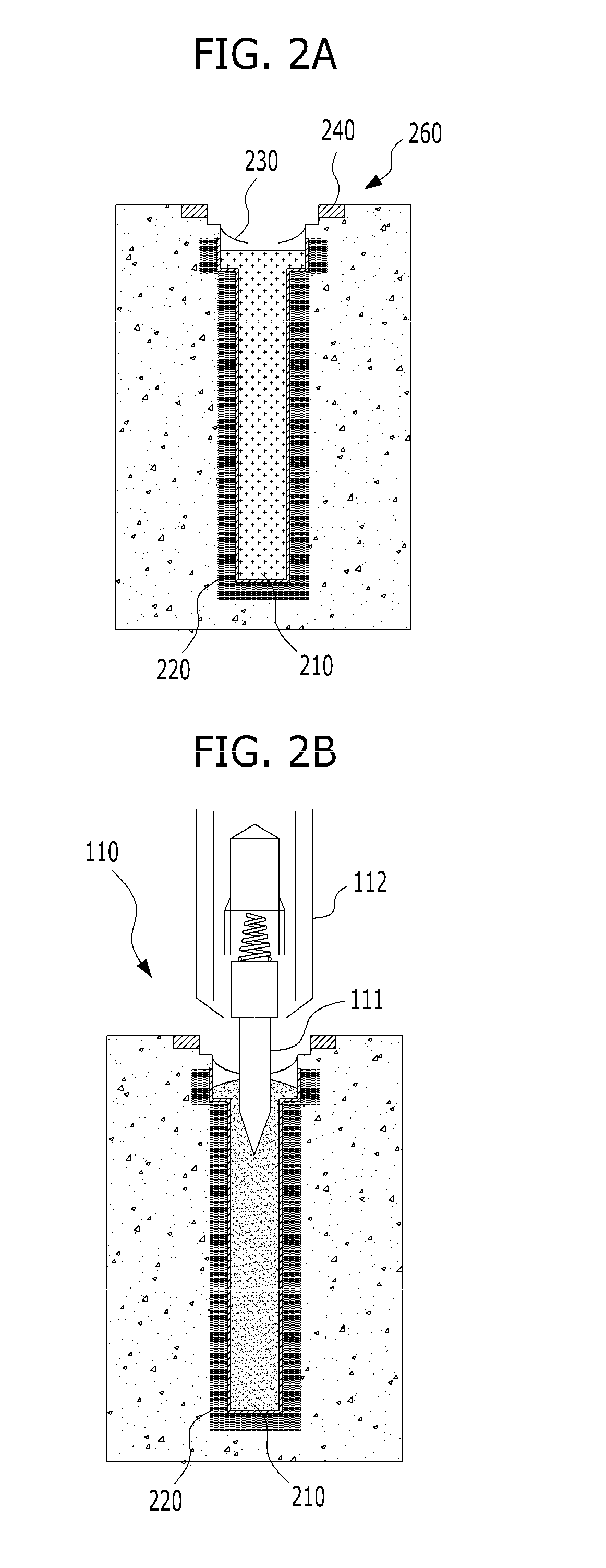

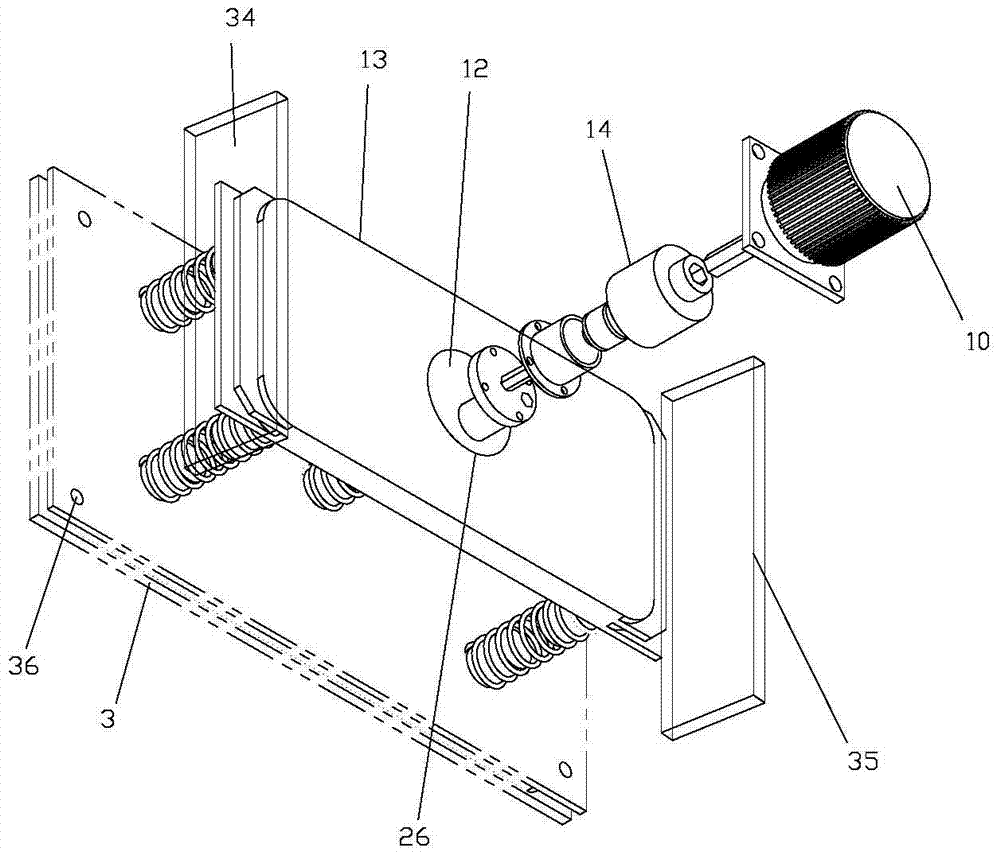

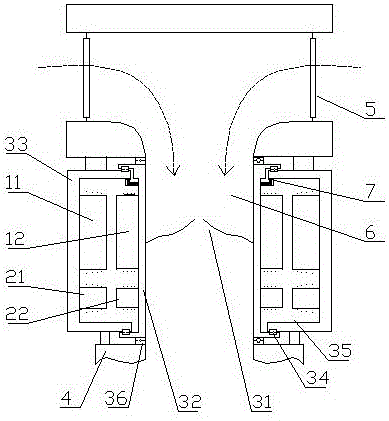

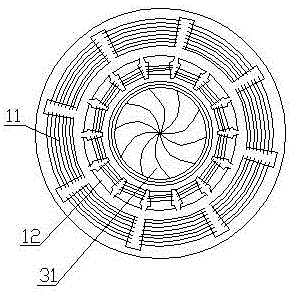

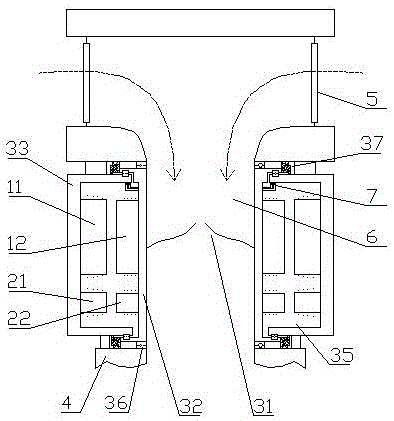

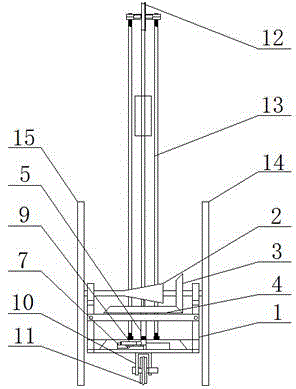

Novel sea wave piezoelectric electricity generation device

InactiveCN106050538AFunction independentImprove power generation efficiencyEngine fuctionsMachines/enginesElectricityPiezoelectric actuators

The invention discloses a novel sea wave piezoelectric electricity generation device which comprises a floating body and a piezoelectric electricity generator. A supporting bottom plate is installed on the outer side of a supporting floating body, a supporting floating body bottom plate is installed on the inner side of the supporting floating body, four guide pillars are installed above the supporting floating body, the piezoelectric electricity generator is installed among the four guide pillars, a top plate is arranged at the top ends of the four guide pillars, and a bearing supporting plate is arranged on the lower portion of the four guide pillars. The piezoelectric electricity generator comprises a surrounding wall arranged among the four guide pillars, piezoelectric vibrators are arranged on the surrounding wall, a transmission shaft is provided with piezoelectric vibrators corresponding to the piezoelectric vibrators on the surrounding wall, permanent magnets are attached to the outer sides of the piezoelectric vibrators, the transmission shaft is connected with a wave energy collecting floating body, a brake device is arranged on a transmission bearing, and an energy storage spring is installed between the bearing supporting plate and the supporting floating body bottom plate. The novel sea wave piezoelectric electricity generation device can effectively prevent the problem of damage to the piezoelectric vibrators of the piezoelectric electricity generation device, and the wave energy utilization rate is increased through the rotary transmission shaft.

Owner:SHANGHAI DIANJI UNIV

Checkweigher for weighing slide way

InactiveCN104535145AReduce frictional energySmall dynamic weighing accuracy problemWeighing apparatus for continuous material flowControl engineeringLoad cell

The invention relates to a checkweigher for weighing a slide way. The checkweigher comprises a third support frame and a fourth support frame, wherein a weighing sensor is arranged on the third support frame, and a weighed slide way which is obliquely placed is arranged on the weighing sensor; an eliminating platform and an eliminating and grading mechanism are arranged on the fourth support frame; the eliminating platform is arranged below a discharge outlet of the weighed slide way; and the weighed slide way is in rigid connection with the stressed end of the weighing sensor through a force guide rod, an included angle between the design stressed direction of the weighing sensor and the material sliding direction of the weighed slide way is B, and B is more than 0 degree and less than 90 degrees or B is more than 90 degrees and less than 180 degrees. The back end of the weighed slide way and the front end of the eliminating platform are opposite with a spacing interval and are not in contact, and the weighed slide way is higher than the front end of the eliminating platform, so that the checkweigher solves the problems that a rotating motion part in a weighing and metering unit of an existing separating and checking scale seriously affects weighing precision, economy, practicality and efficiency, as well as the problems that an eliminating and grading device affects the weighing precision and the manufacturing, debugging and maintenance cost.

Owner:SHANDONG SETAQ INSTR

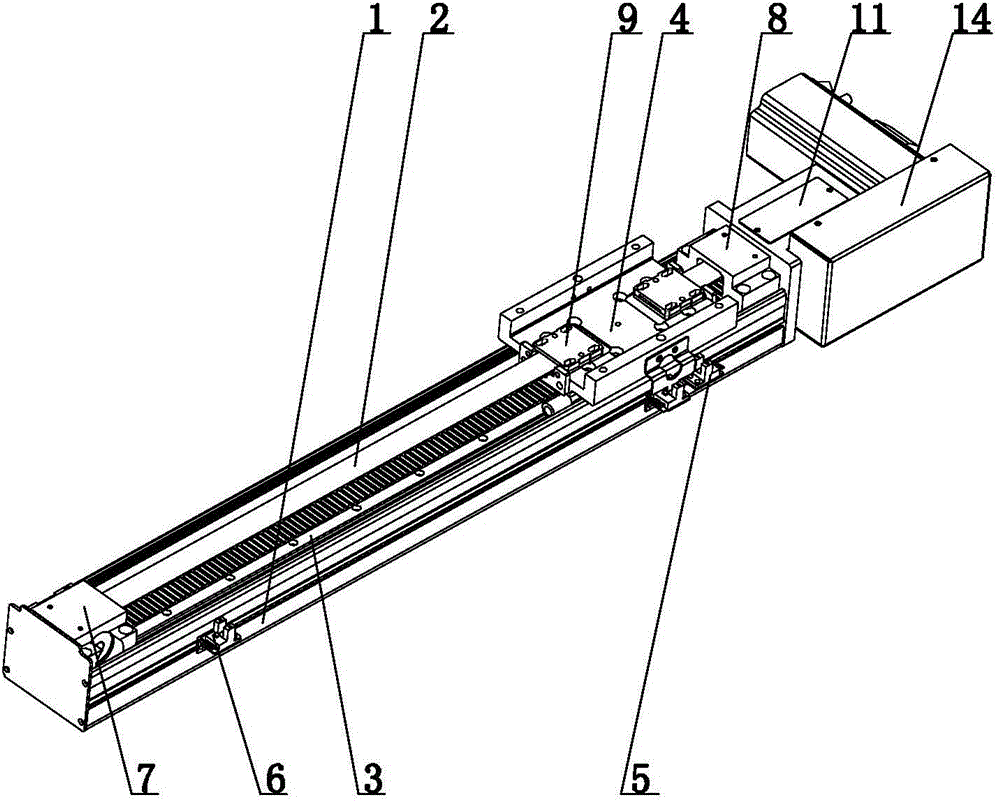

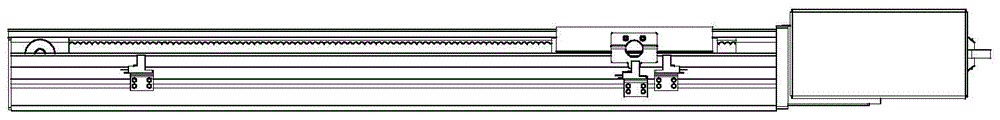

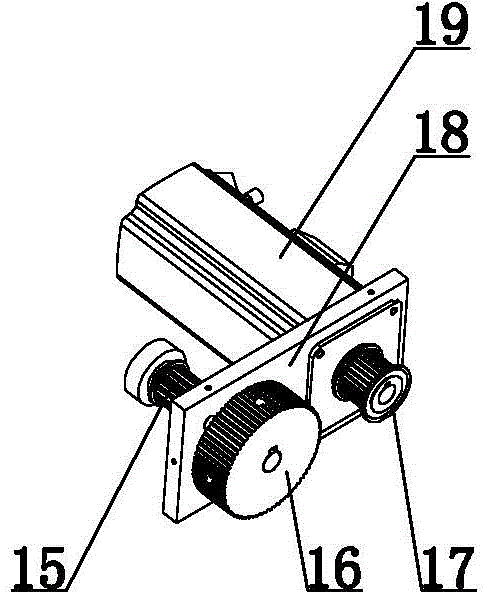

Electronic sliding table

InactiveCN104889747AHigh precisionReduce frictional resistanceFeeding apparatusLarge fixed membersLow noiseMechanical drive

The invention relates to a mechanical transmission device and particularly relates to an electronic sliding table. The electronic sliding table comprises a sliding table base, a guide rail is arranged on the sliding table base, a sliding fixation block structure, a front fixation block and a rear fixation block are arranged at the two ends of the sliding table base respectively, the rear fixation block is connected with a tail end fixation block, and a driving structure for driving the sliding fixation block structure to move is arranged in the tail end fixation block. The electronic sliding table has the advantages of being ingenious and simple in design, low in noise, wide in use range, convenient to mount, high in accuracy and acceptable to the majority of users.

Owner:宁波麦科斯机器人科技有限公司

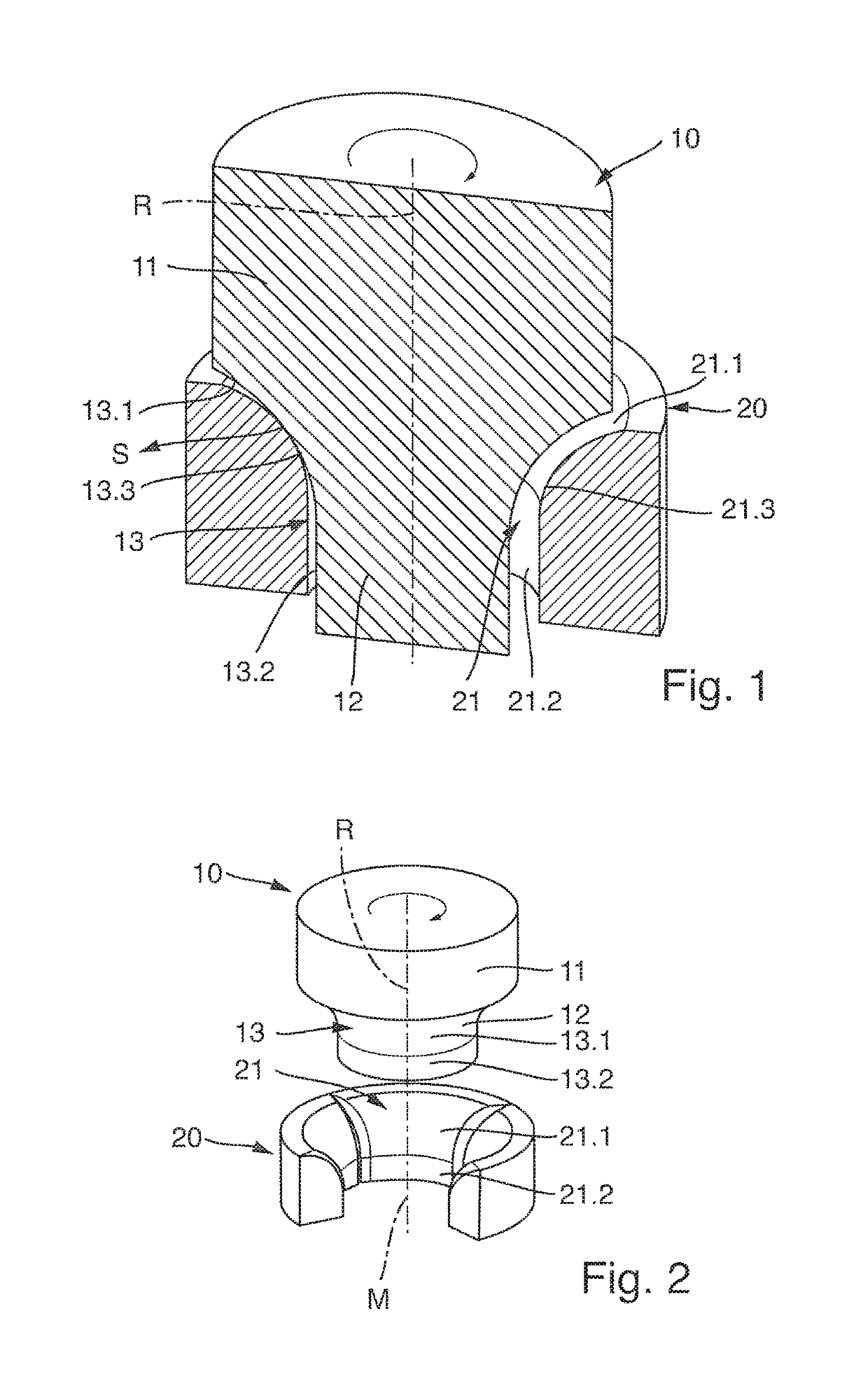

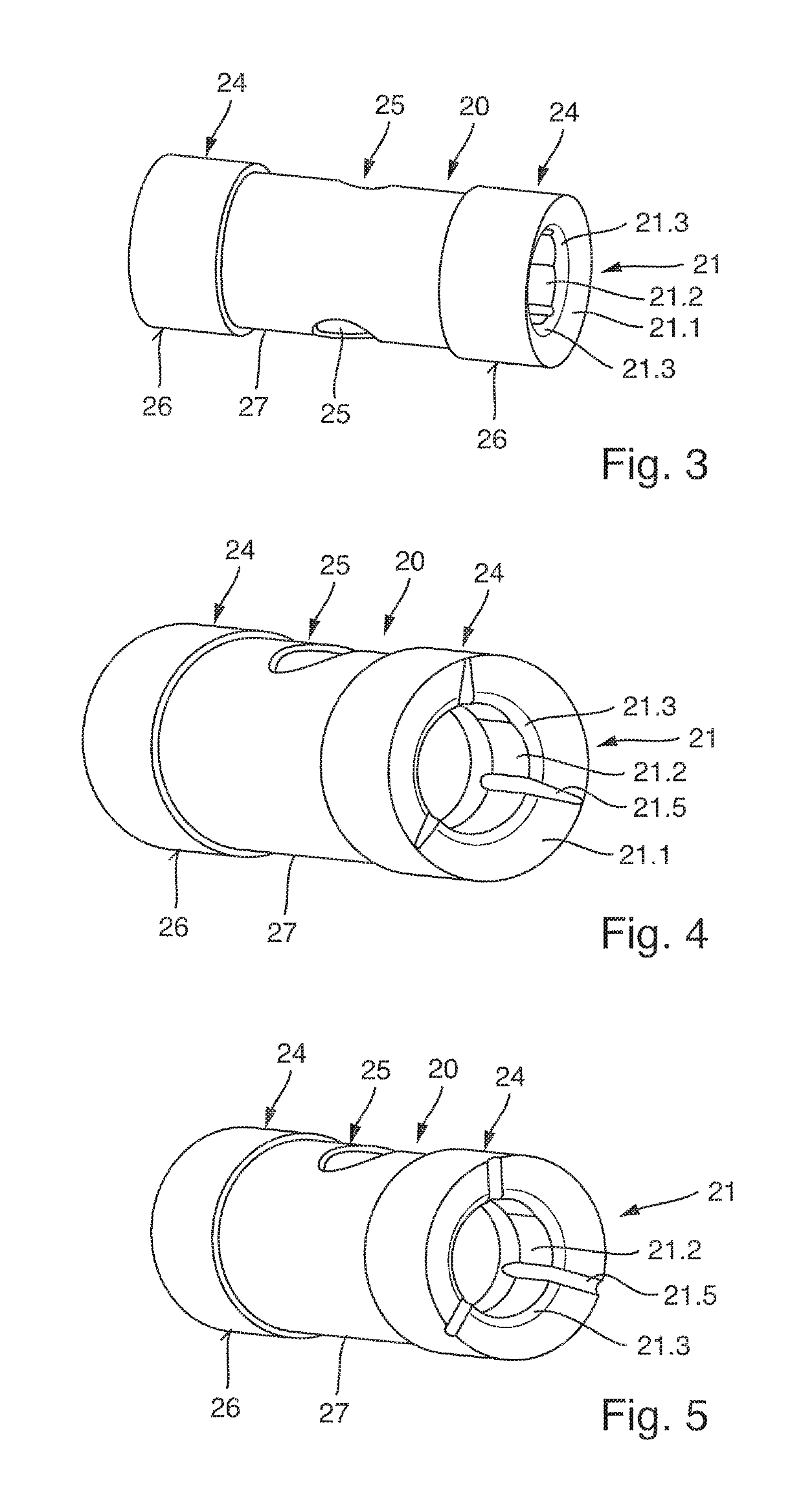

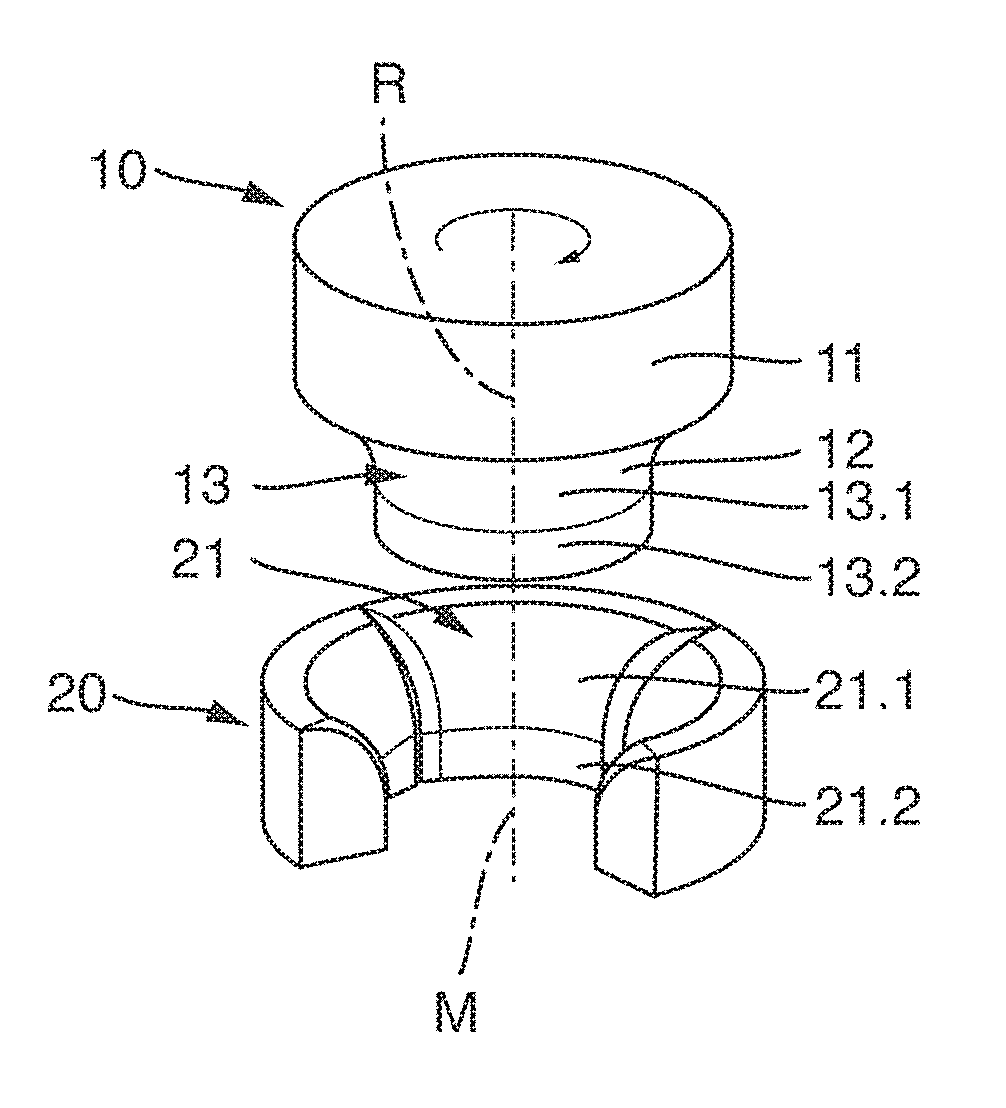

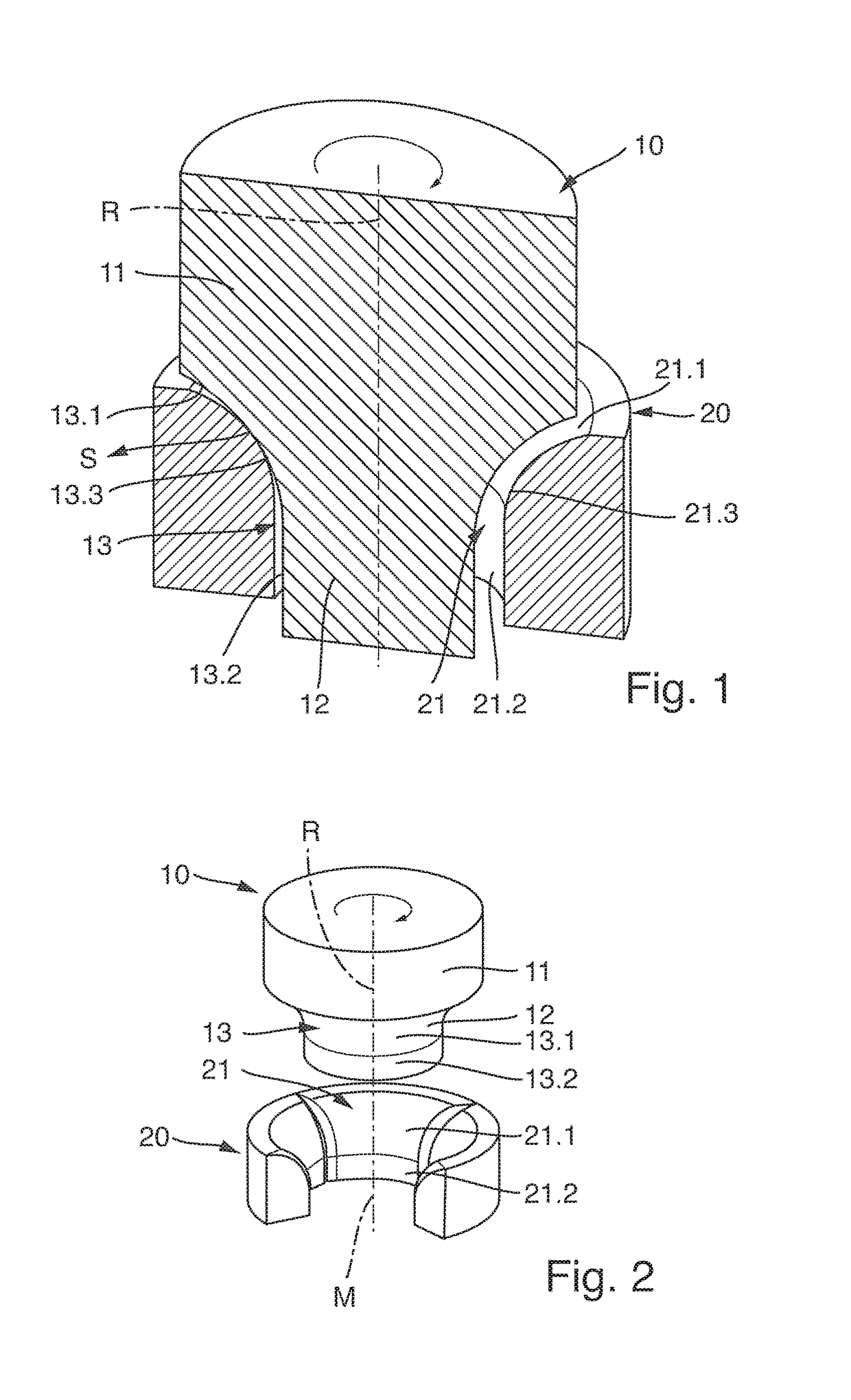

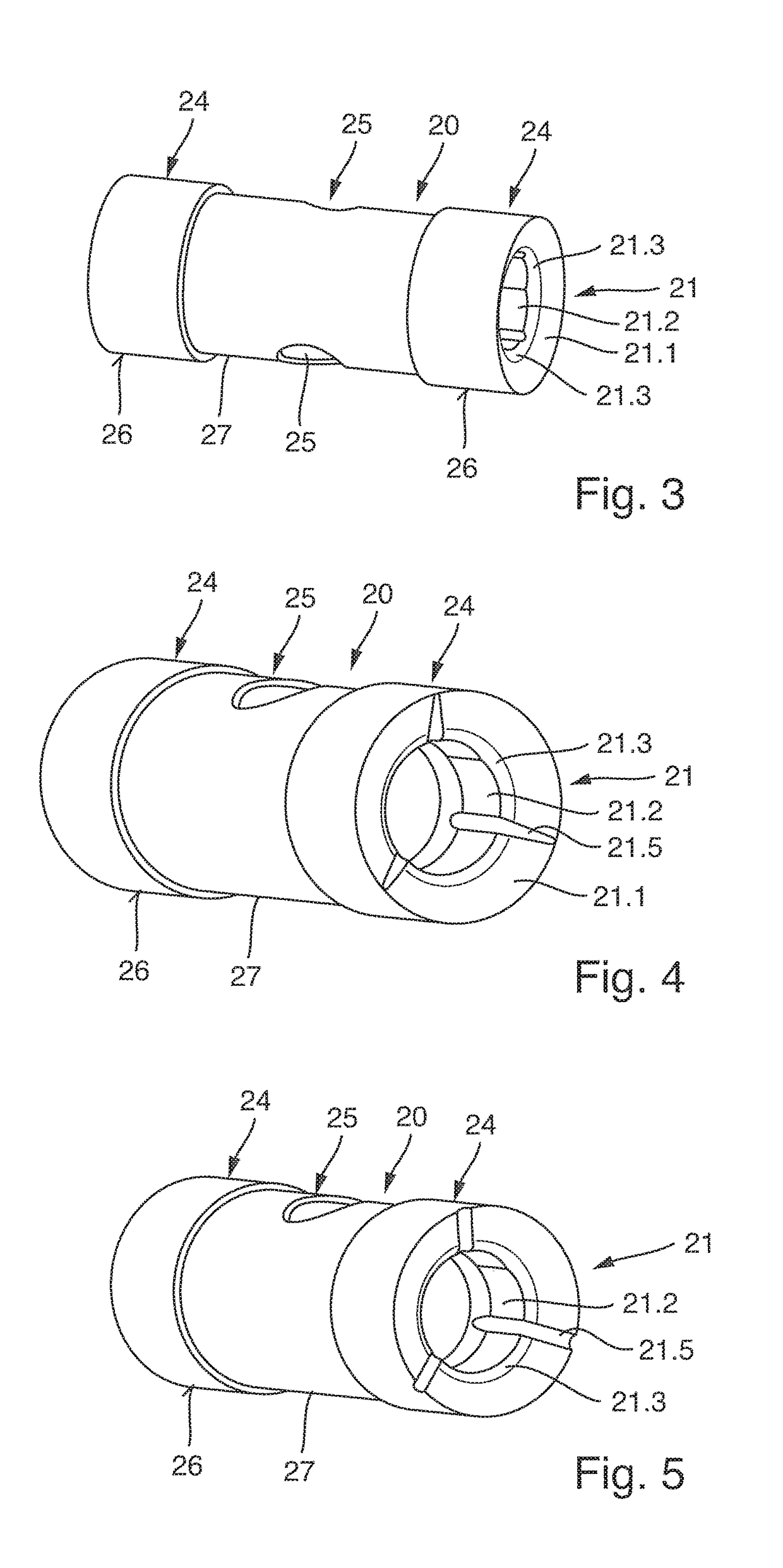

Hydrodynamic plain bearing and exhaust-gas-driven turbocharger

A hydrodynamic plain bearing having a stator and a rotor rotatable with respect to the stator, a rotor bearing surface being located opposite a counter-surface of the stator in order to generate hydrodynamic pressure. The rotor bearing surface and / or the counter-surface constitutes in a section view, in the context of a section along and through the rotation axis, a continuous bearing contour that is constituted from at least two contour segments. The contour segments are suitable for generating hydrodynamic load capacity in a radial and axial direction. The contour segments are led into one another, by at least one transition segment, in such a way that hydrodynamic load capacity is generatable via the contour segments and the transition segment. The plain bearing is embodied as a multiple-surface plain bearing having two or more lubrication wedges in the region of the contour segments and of the transition segment.

Owner:BOSCH MAHLE TURBO SYST GMBH & CO KG

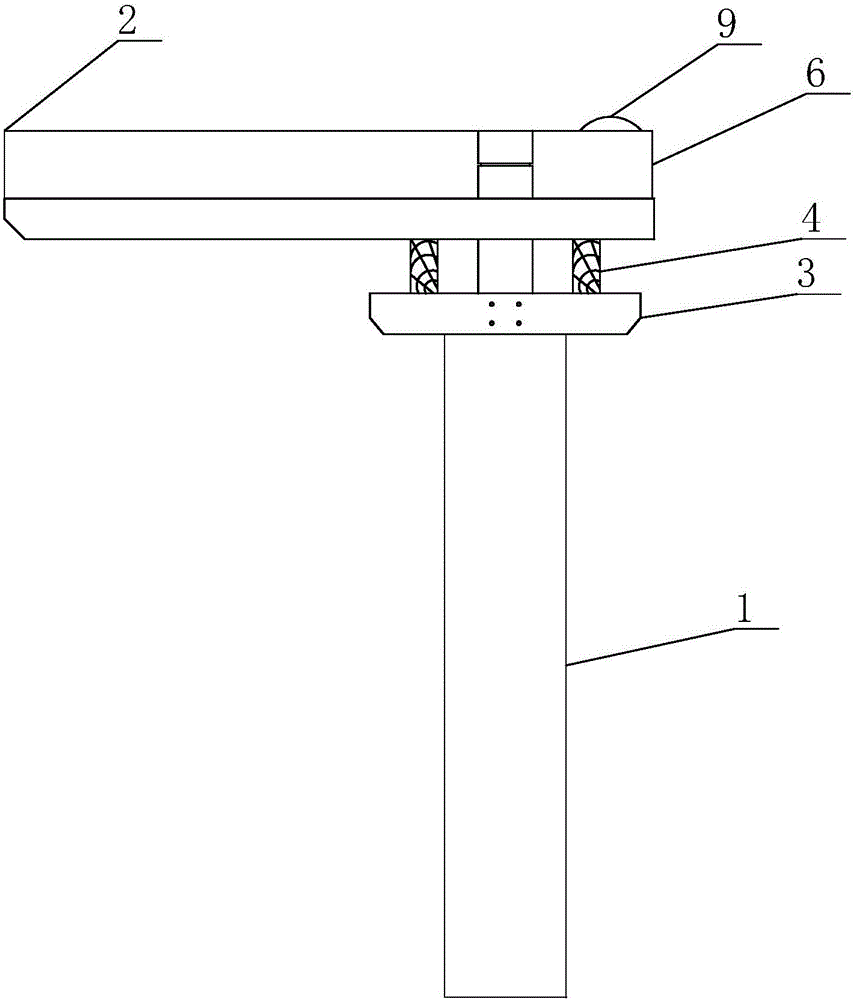

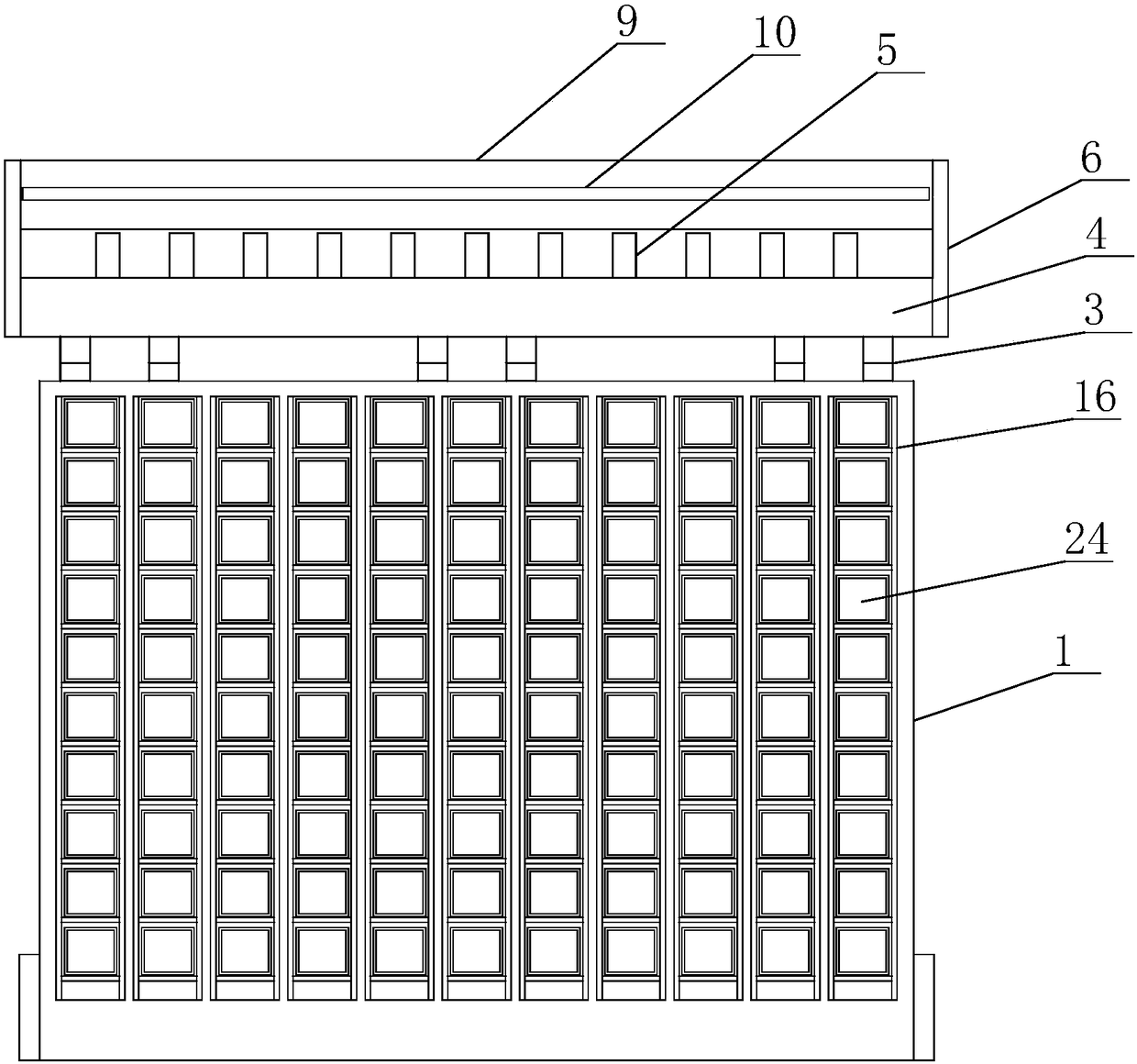

Integrated landscape piece type flower stand

InactiveCN105815149ALayout diversificationExquisite local shapeSpecial buildingCultivating equipmentsLandscape designEngineering

The invention discloses an integrated landscape piece type flower stand and mainly relates to the field of landscape design. The integrated landscape piece type flower stand comprises a flower wall frame and a shed frame, wherein a sun and rain canopy is arranged on the shed frame; the sun and rain canopy can be reeled into a barrel body at one end of the shed frame; a plurality of strip-shaped grooves are arrayed on the flower wall frame; the strip-shaped grooves are internally provided with a driving belt which circularly rotates up and down; the driving belt is provided with inserting plates; flower boxes are movably inserted into the inserting plates. The integrated landscape piece type flower stand has the beneficial effects that a design of combining designs of the flower stand and a three-dimensional plant modeled wall is adopted, so that a resting facility can be provided for customers, and green plant landscapes can also be established in a top-layer space and a vertical space from a plurality of angles; the integrated landscape piece type flower stand is convenient to assemble and has functions of shielding rain and snow, so that the whole layout of gardens is relatively diversified, and partial modeling is relatively exquisite.

Owner:SHANDONG UNIV OF SCI & TECH

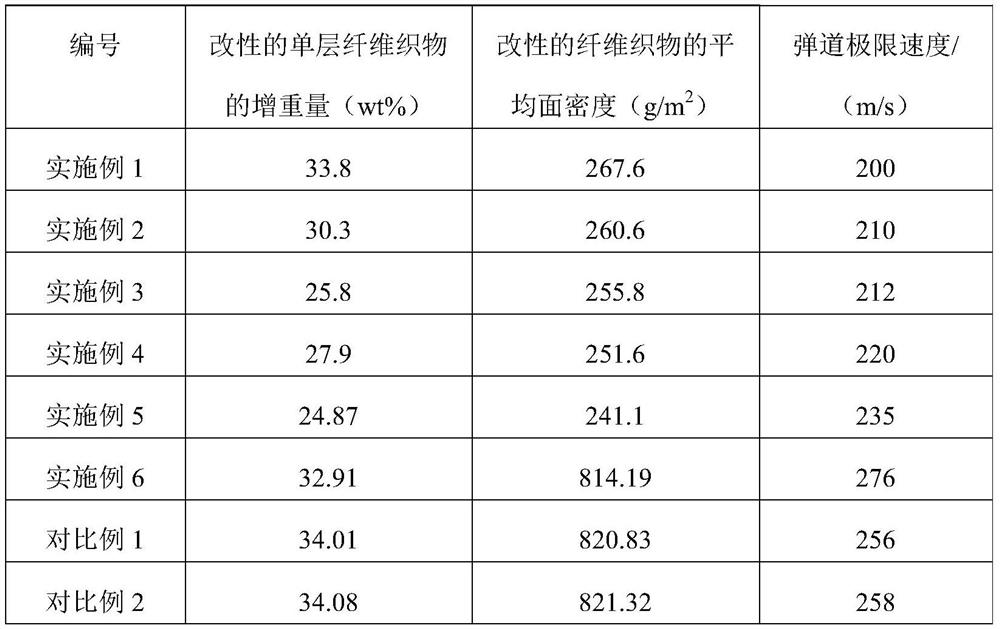

Shear thickening protective liquid and application thereof

ActiveCN111910436AReduced shear thickening effectImprove ballistic performanceFibre treatmentFiberSilica particle

The invention relates to a shear thickening protective liquid and application thereof, and belongs to the technical field of shear thickening liquids. The shear thickening protective liquid is composed of polyethylene glycol, nano silicon dioxide powder and boron carbide powder; according to the shear thickening protective liquid, under the cooperation of boron carbide particles and silicon dioxide particles, on one hand, friction is increased, and the principle of friction energy absorption between the particles is fully utilized; and on the other hand, the degree of shear failures during impregnation of a fiber fabric can be reduced, and energy absorption of the fiber fabric to shots is increased. The shear thickening protective liquid disclosed by the invention has a better bulletproofeffect in the field of fiber fabric modification, and can be widely applied to the field of different types of protective equipment.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Hydrodynamic Plain Bearing and Exhaust-Gas-Driven Turbocharger

ActiveUS20180073553A1Utilization propertyLess emissionsShaftsBearing componentsTurbochargerEngineering

The invention relates to a hydrodynamic plain bearing having a stator and a rotor rotatable with respect to the stator, a rotor bearing surface being located opposite a counter-surface of the stator in order to generate hydrodynamic pressure. In order to achieve improved utilization properties, provision is made according to the present invention that the rotor bearing surface and / or the counter-surface constitutes in a section view, in the context of a section along and through the rotation axis, a continuous bearing contour that is constituted from at least two contour segments; that the contour segments are suitable for generating hydrodynamic load capacity in a radial and axial direction; that the contour segments are led into one another, by means of at least one transition segment, in such a way that hydrodynamic load capacity is generatable via the contour segments and the transition segment; and that the plain bearing is embodied as a multiple-surface plain bearing having two or more lubrication wedges in the region of the contour segments and of the transition segment).

Owner:BOSCH MAHLE TURBO SYST GMBH & CO KG

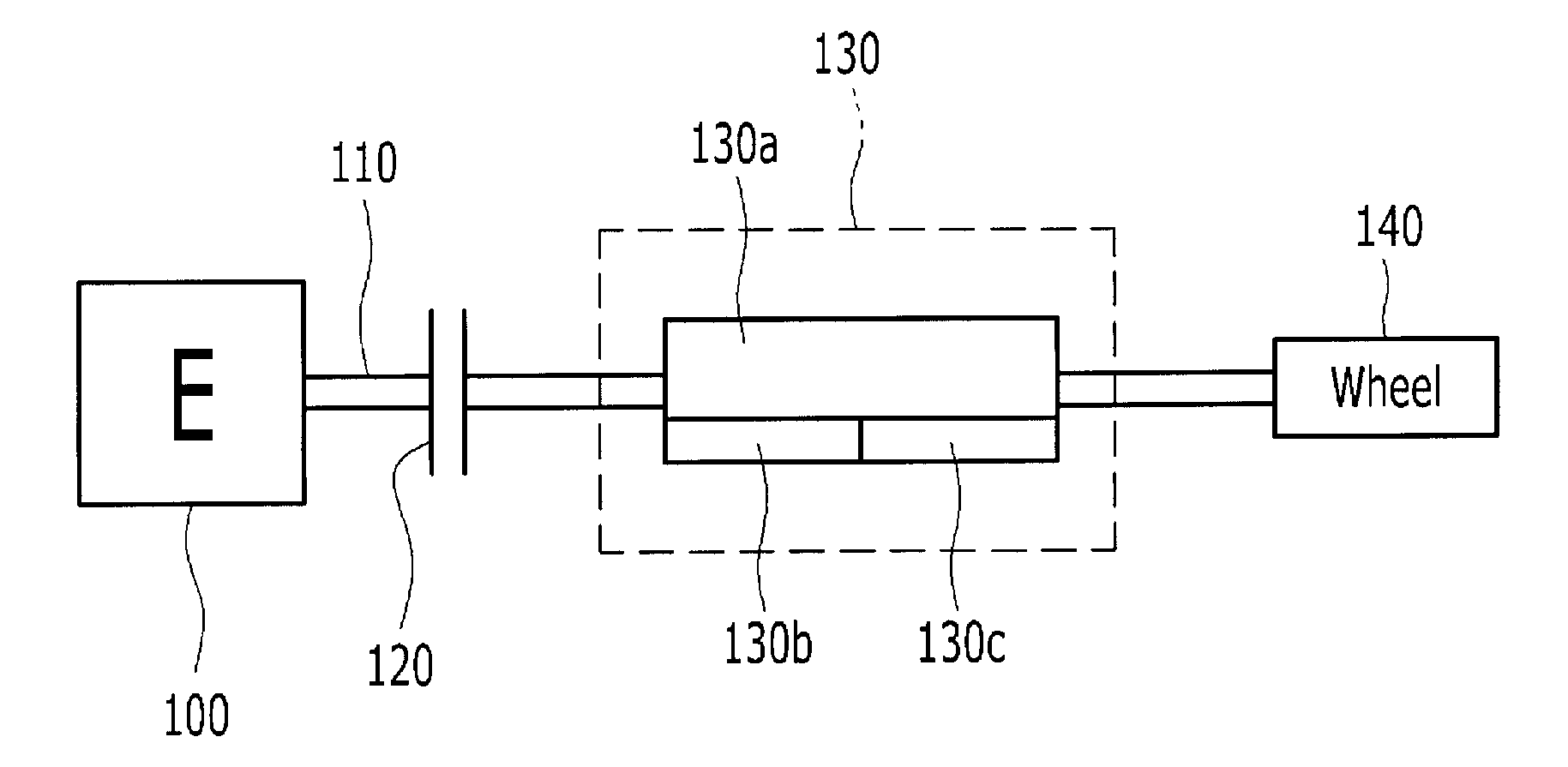

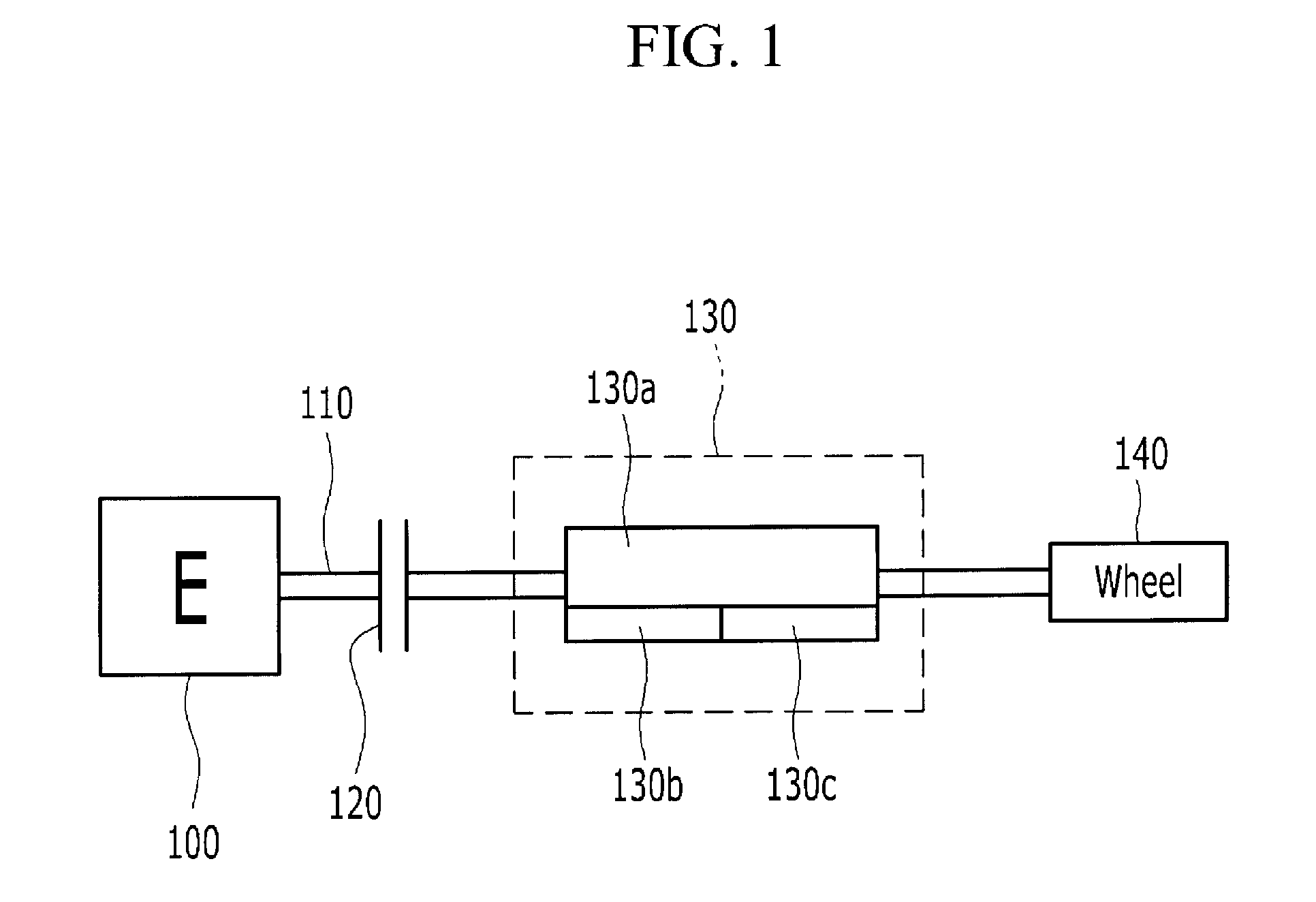

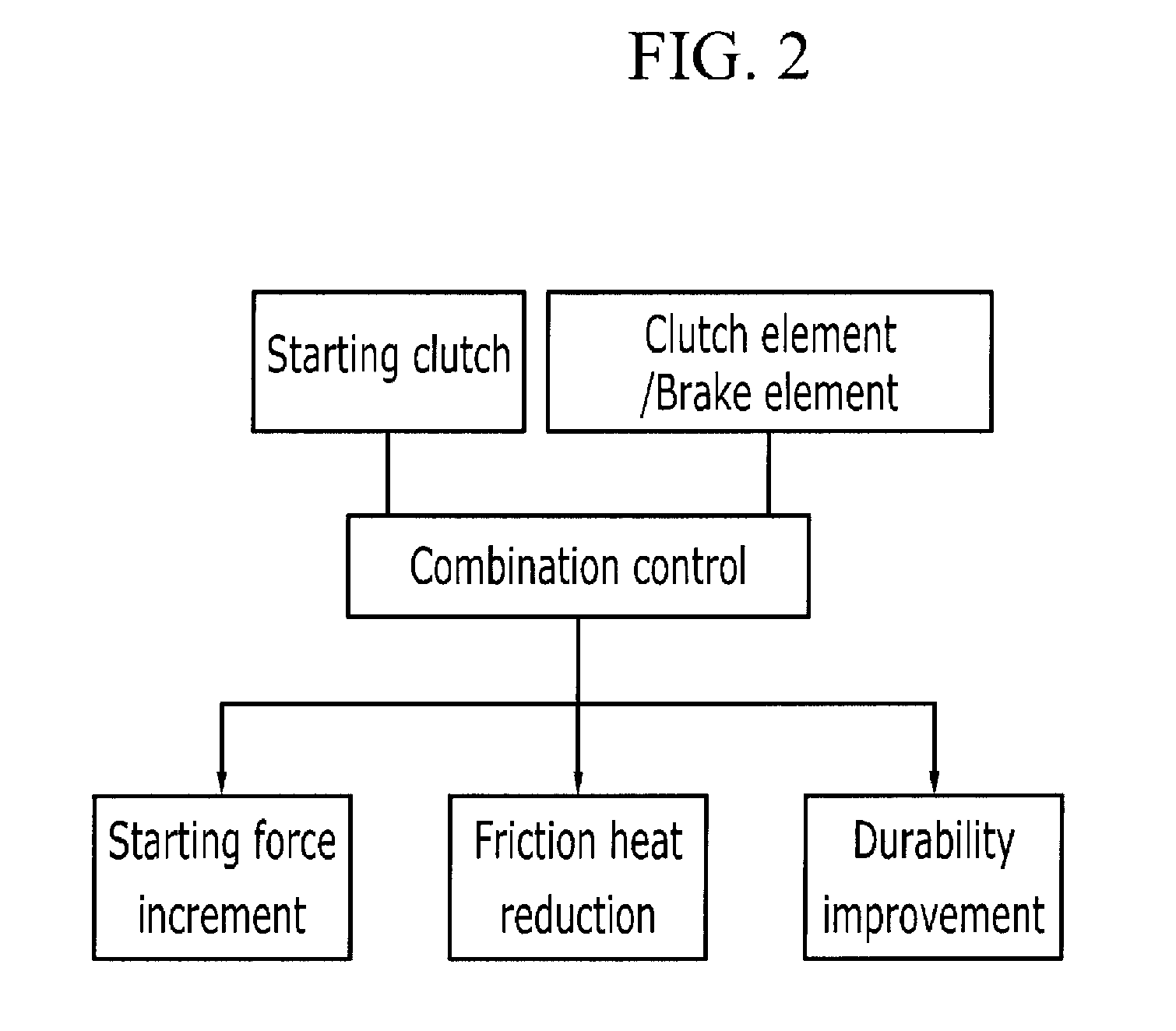

Clutch control method

InactiveUS20120035018A1Friction energy be reduceDurability and transmission efficiency be improveClutchesEngine controllersEngineeringClutch control

A clutch control may include a starting clutch that is disposed at a rear portion of an engine, an automatic transmission that is disposed at a rear portion of the starting clutch and uses a shifting element to vary a rotation ratio between an input shaft and an output shaft thereof, a driving wheel that receives a torque of the engine through the starting clutch and the automatic transmission to move a vehicle, and a control portion that combinatively slips the starting clutch and the shifting element. Accordingly, the starting clutch and the shifting element (clutch element or brake element) of the transmission are combinatively slip-controlled such that the friction energy is reduced, and the durability and the transmission efficiency are improved.

Owner:HYUNDAI MOTOR CO LTD

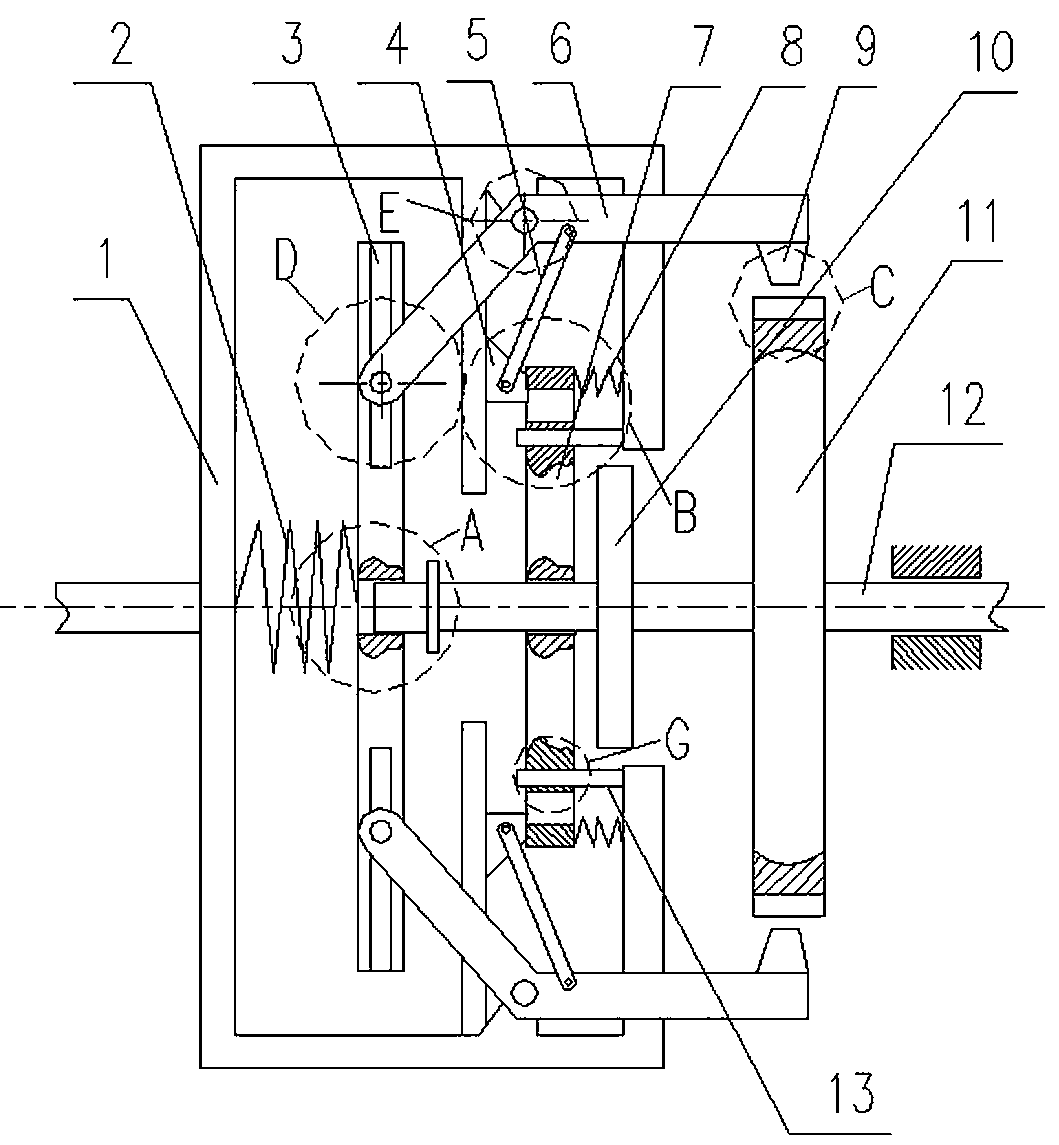

Overload protection device for power transmission and transformation equipment of wind power farm

PendingCN108374755AAvoid Load SituationsExtended service lifeWind motor controlMachines/enginesStopped workEngineering

The invention discloses an overload protection device for power transmission and transformation equipment of a wind power farm. The overload protection device comprises a casing, wherein a variable-pitch head is arranged at the left side of the casing. The overload protection device has the beneficial effects that when the air speed is increased, the leftmost end of a drive plate disengages from the rightmost end of a limiting plate, and a power generator stops working, so as to avoid the load condition of the power generator due to overquick rotation speed of the power generator because of overhigh air speed, and prolong the service lives of the power generator and a speed-variable gearbox; when the air speed is too high, the variable-pitch head is in contact with a sleeve cylinder cover,and is rotated relatively to the sleeve cylinder cover, so as to protect the variable-pitch head; when the air speed is reduced, the drive plate and the limiting plate are re-embedded under the resetaction of a spring, and the power generator generates power again; the right end of the limiting plate is in an arc shape with concave right side, the right end of the limiting plate is of a structure with narrow right part and wide left part, and then the drive plate can easily enter the gap of the limiting plate when the drive plate rotates.

Owner:XINZHOU POWER SUPPLY COMPANY STATE GRID SHANXI ELECTRIC POWER

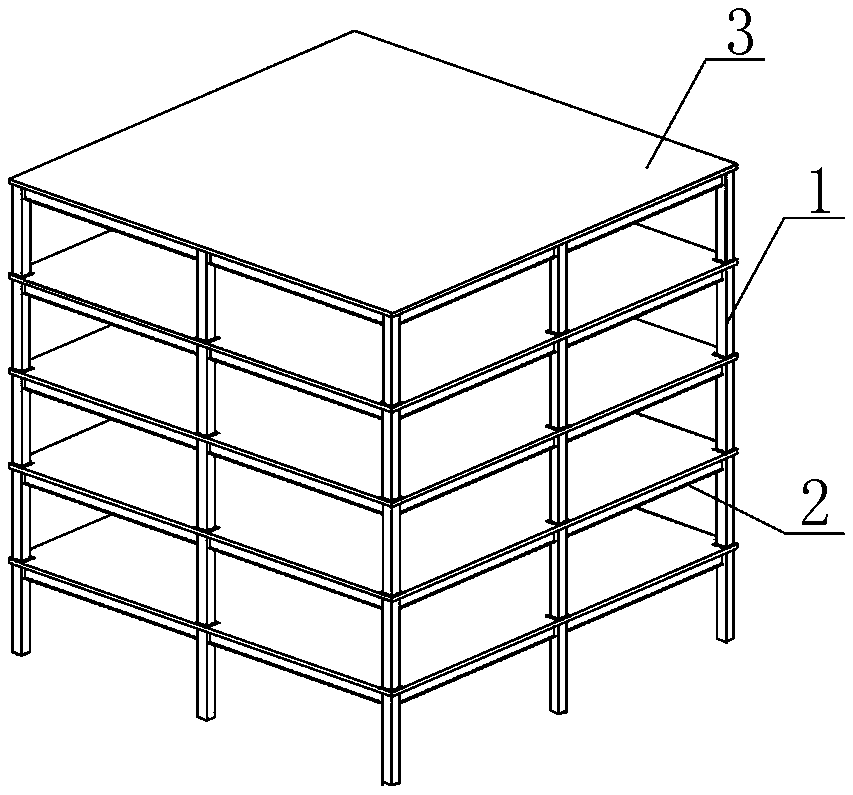

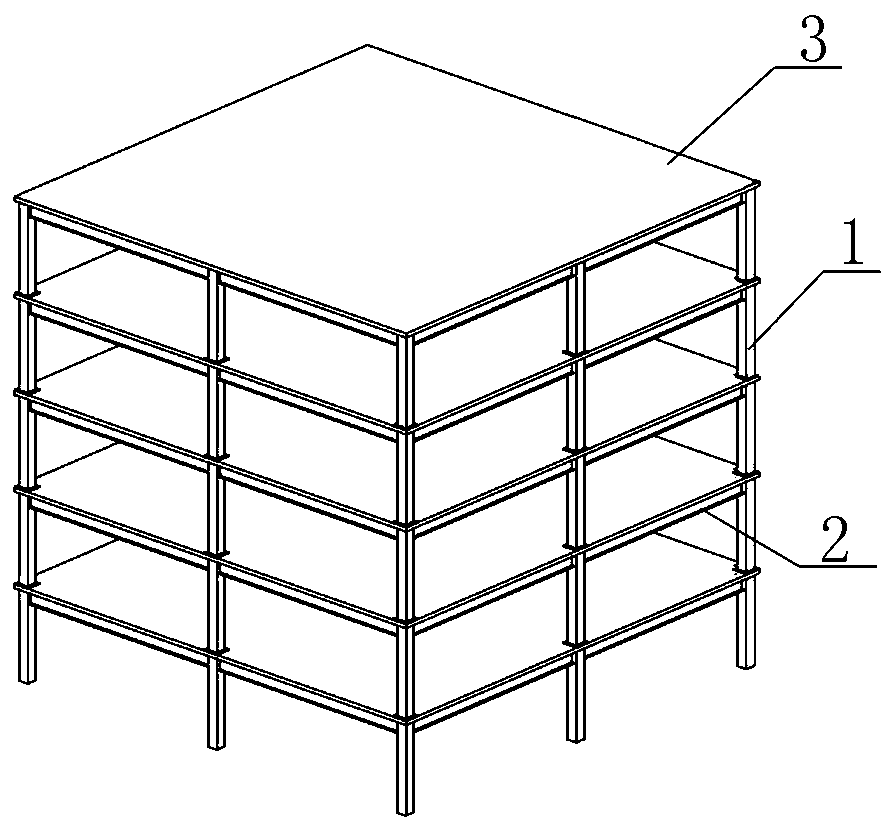

Prestress column tenon connection steel structure system and design method thereof

ActiveCN110409605AImprove seismic performanceEfficient assemblyProtective buildings/sheltersSpecial data processing applicationsFloor slabSteel columns

The invention provides a prestress column tenon connection steel structure system and a design method thereof. The prestress column tenon connection steel structure system comprises at least two layers of steel-frame structures stacked in the vertical direction; steel columns of each layer of the steel-frame structure are broken at the connecting parts between the steel columns and the lower layers of floor slabs; adjacent steel-frame structures are connected through prestress column tenon connection structures; the prestress column tenon connection structures comprise through holes, top sleeving tenons, elastic materials and high-strength pulling cables; the through holes are formed in the tops of the steel columns of the lower layers of the steel-frame structures; the top sleeving tenonsare connected with the bottoms of the steel columns of the upper layers of the steel-frame structures; the top sleeving tenons at the bottoms of the steel columns are correspondingly inserted into the through holes in the tops of the steel columns; gaps are reserved between the side walls of the top sleeving tenons and the side walls of the through holes; gaps are reserved between the tops of thethrough holes and the bottoms of the steel columns of the upper layers of the steel-frame structures; the elastic materials are arranged in the gaps between the top sleeving tenons and the through holes; and the high-strength pulling cables penetrate through the steel columns vertically corresponding in the steel structure system. The technical problem that a traditional steel structure is low inconstruction efficiency, severe in environmental pollution and poor in connecting joint anti-seismic property is solved.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

Bituminous composition in the form of granules and method for preparing same

Disclosed is a bituminous composition in the form of granules, each granule including a core and a coating and having a mass for approximately one hundred particles of from 0.5 g to 2 g, the core including from 40 wt. % to 60 wt. % of a binder matrix; from 30 wt. % to 40 wt. % of a polymer; from 4 wt. % to 6 wt. % of a compatibilizing agent; and from 2 wt. % to 15 wt. % of an anti-adhesive filler; and the coating including an anti-sticking agent. The invention relates also to a method for preparing the composition, and to the use thereof in bitumen plants.

Owner:EIFFAGE INFRASTRUCTURES

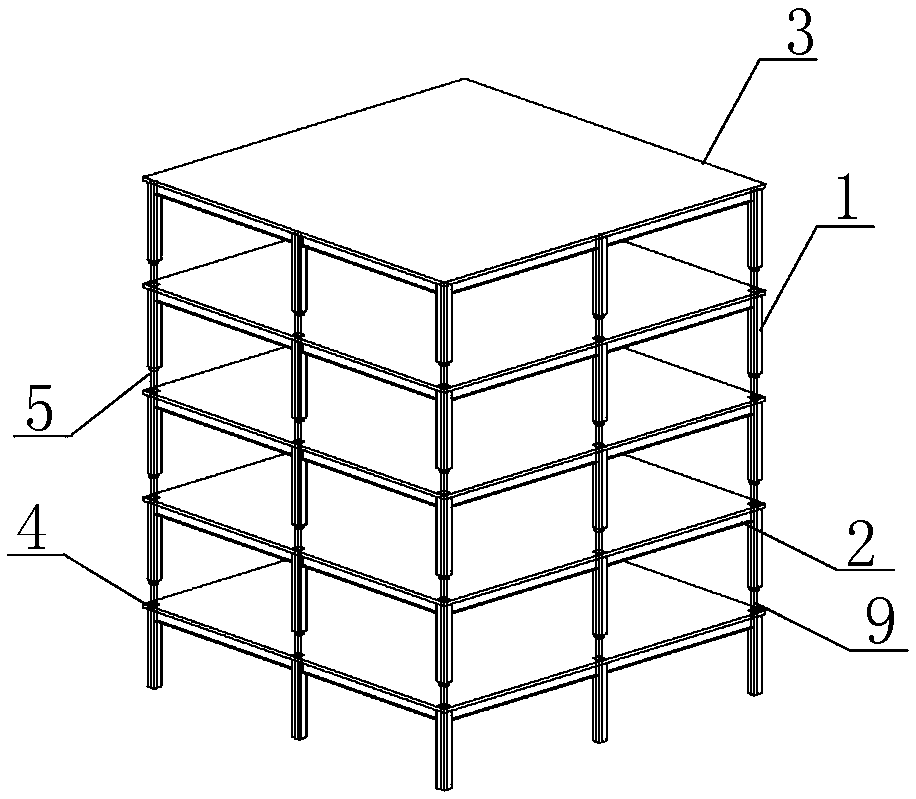

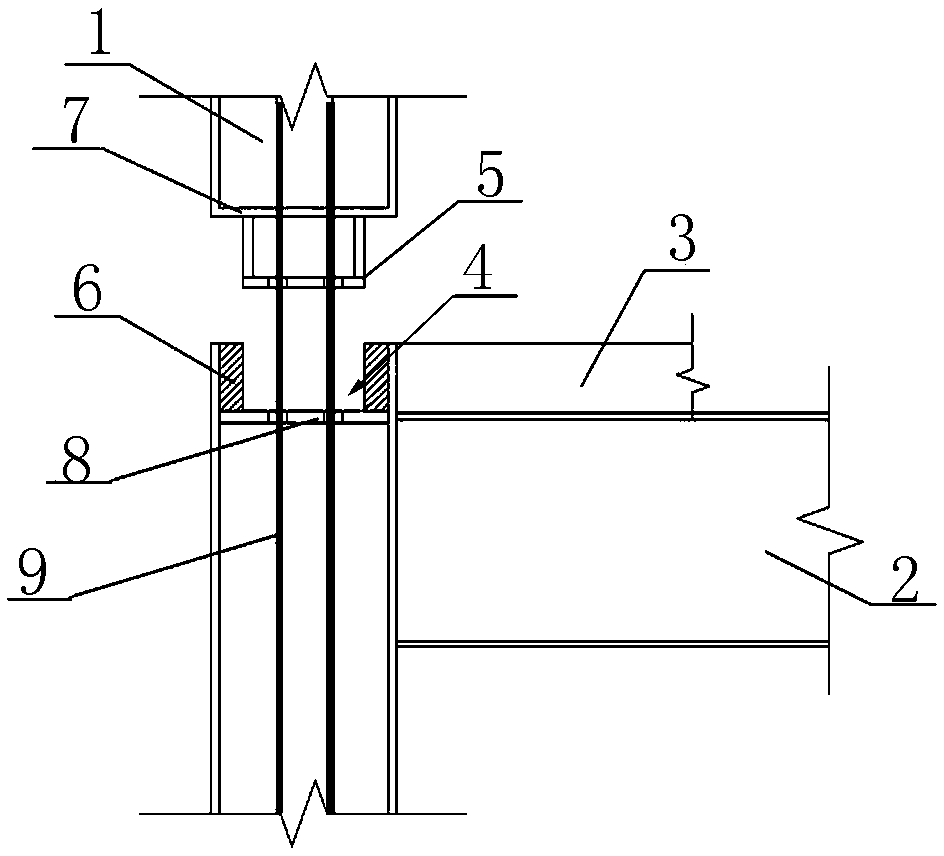

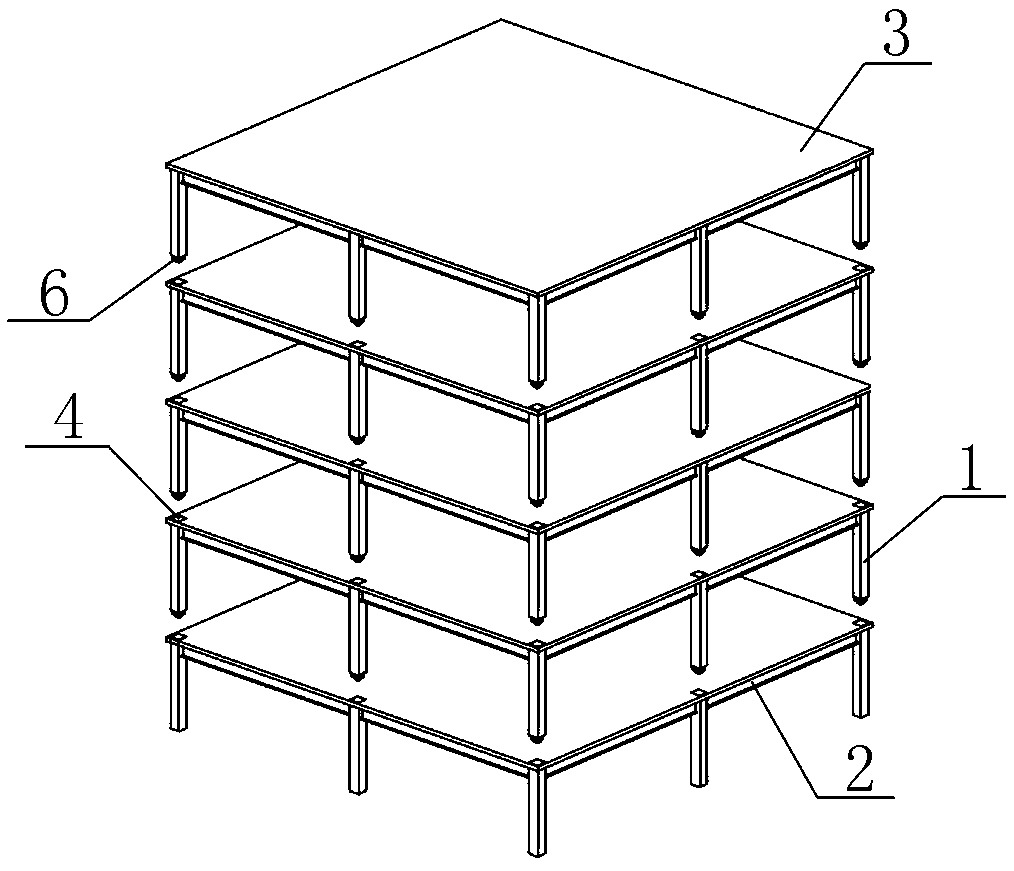

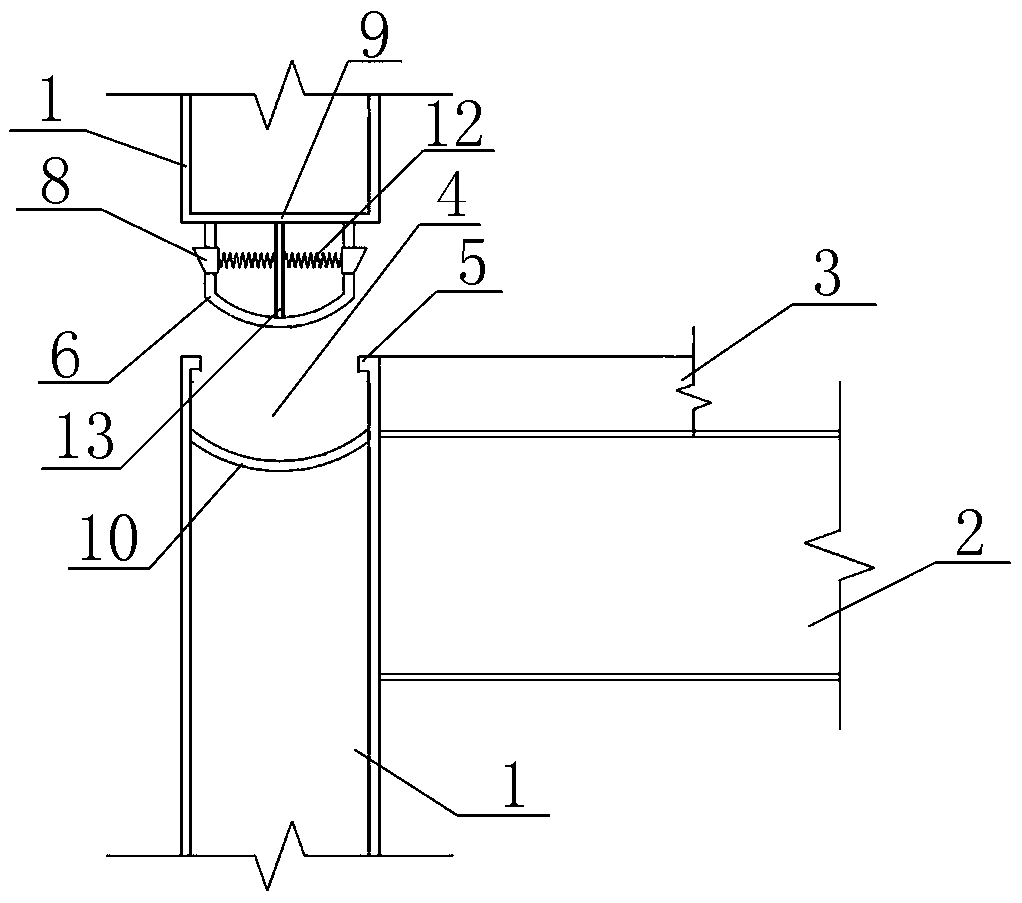

Assembled column pestle connected steel structure system and design method thereof

ActiveCN110409607AImprove seismic performanceAchieving Frictional Energy DissipationProtective buildings/sheltersSpecial data processing applicationsElastic componentFloor slab

An assembled column pestle connected steel structure system and a design method thereof comprise at least two layers of steel frame structures which are vertically stacked; the steel columns of the two vertically adjacent layers of steel frame structures are disconnected with a floor slab at the lower layer, and the steel columns between the two adjacent layers of steel frame structures are connected through a pestle; the top of each steel column in the lower steel frame structure is provided with a mortise; the bottom surface of the mortise is a concave curved surface which is sunken downwards, and the top of the mortise is provided with a clamping edge; the bottom of the steel column in the upper-layer steel frame structure is provided with a tenon, and the bottom surface of the tenon isconvexly curved; the tenon at the bottom of the upper-layer steel column is correspondingly inserted into the mortise at the top of the lower-layer steel column, a space is reserved between the tenonand the clamping edge, and a space is reserved between the top of the mortise and the bottom of the upper-layer steel column; the vertical side wall of the tenon is provided with a spring block; andan elastic component which ejects an elastic block is arranged in the tenon. The assembled column pestle connected steel structure system solves the technical problems of complex structure, poor construction efficiency, poor seismic energy dissipation performance and poor seismic performance of the traditional assembled steel structure building node.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

Garbage recycling device with multi-section type sliding cover

InactiveCN108482901AReasonable settingMany types of recyclingRefuse receptaclesEngineeringWaste management

Owner:广东沫益清环保科技有限公司

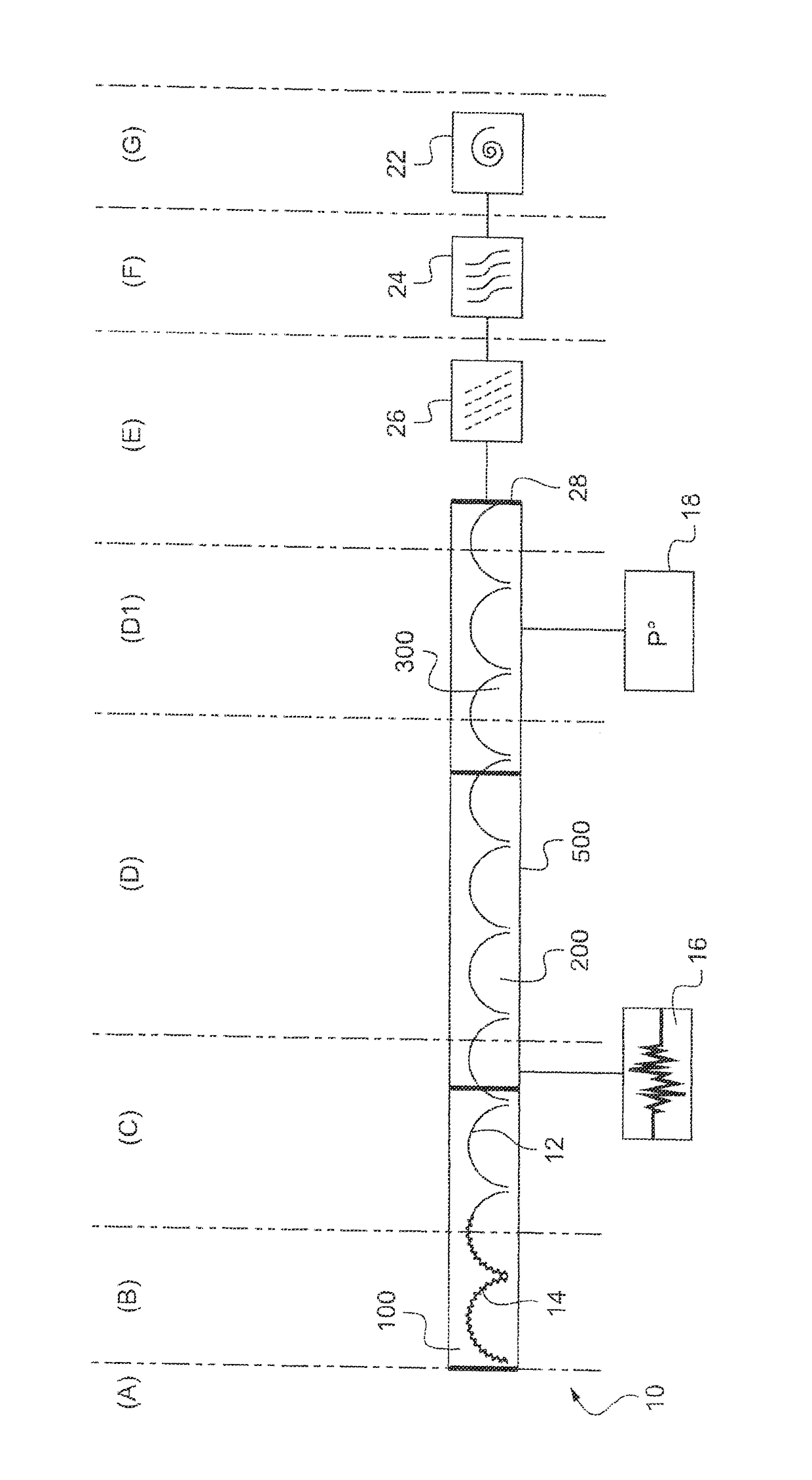

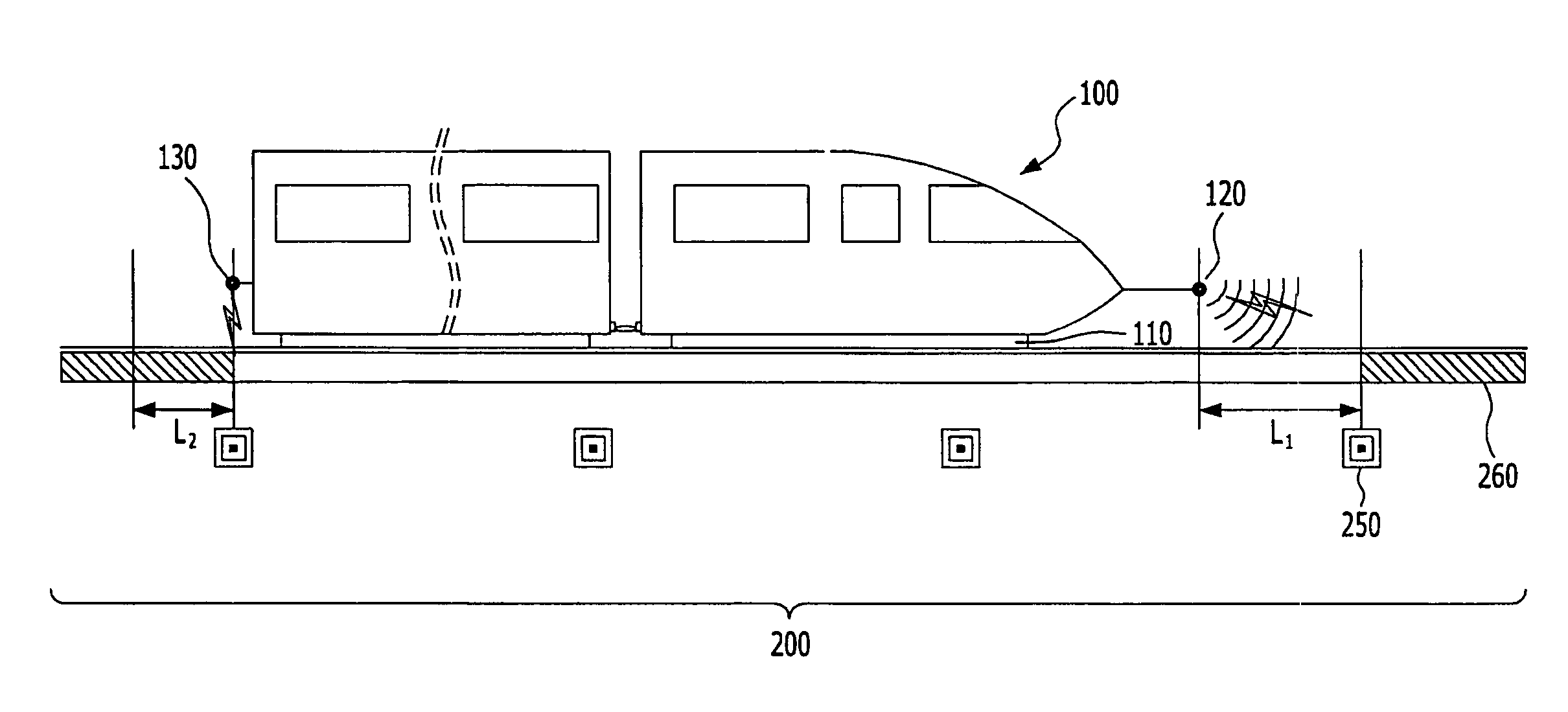

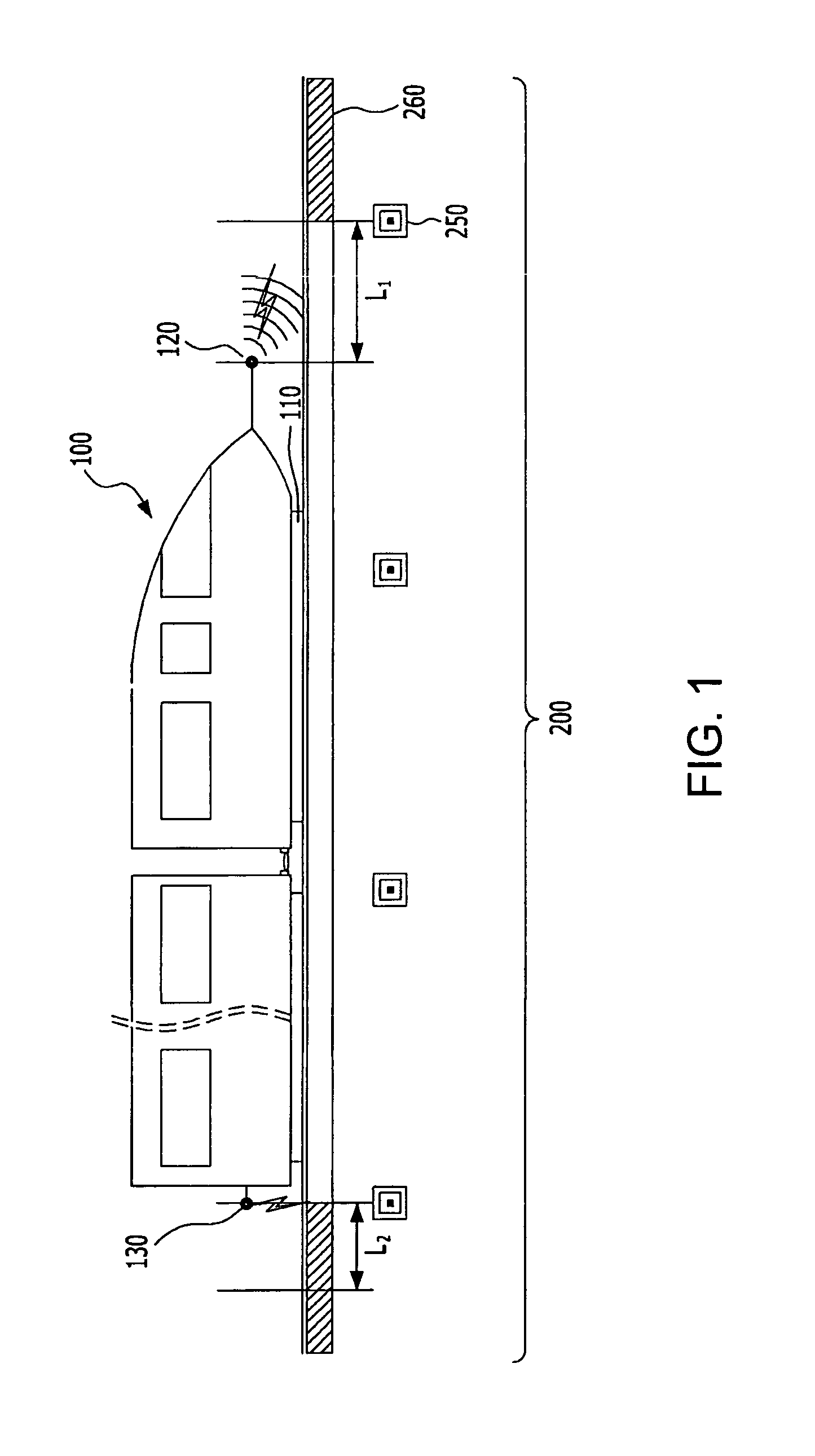

Transportation apparatus having induced freezing rail system

InactiveUS20110146322A1Reduce frictional energy lossReduce noiseLighting and heating apparatusRailway tracksRefrigerantTransport engineering

A transportation apparatus configured to travel on rails and having an induced freezing rail system includes: a transportation vehicle having a support unit configured to support a frame from the rails; and a freezing rail system comprising freezing rails positioned on a ground surface corresponding to the support unit of the transportation vehicle, the freezing rails having a refrigerant and cooling devices.

Owner:ELECTRONICS & TELECOMM RES INST

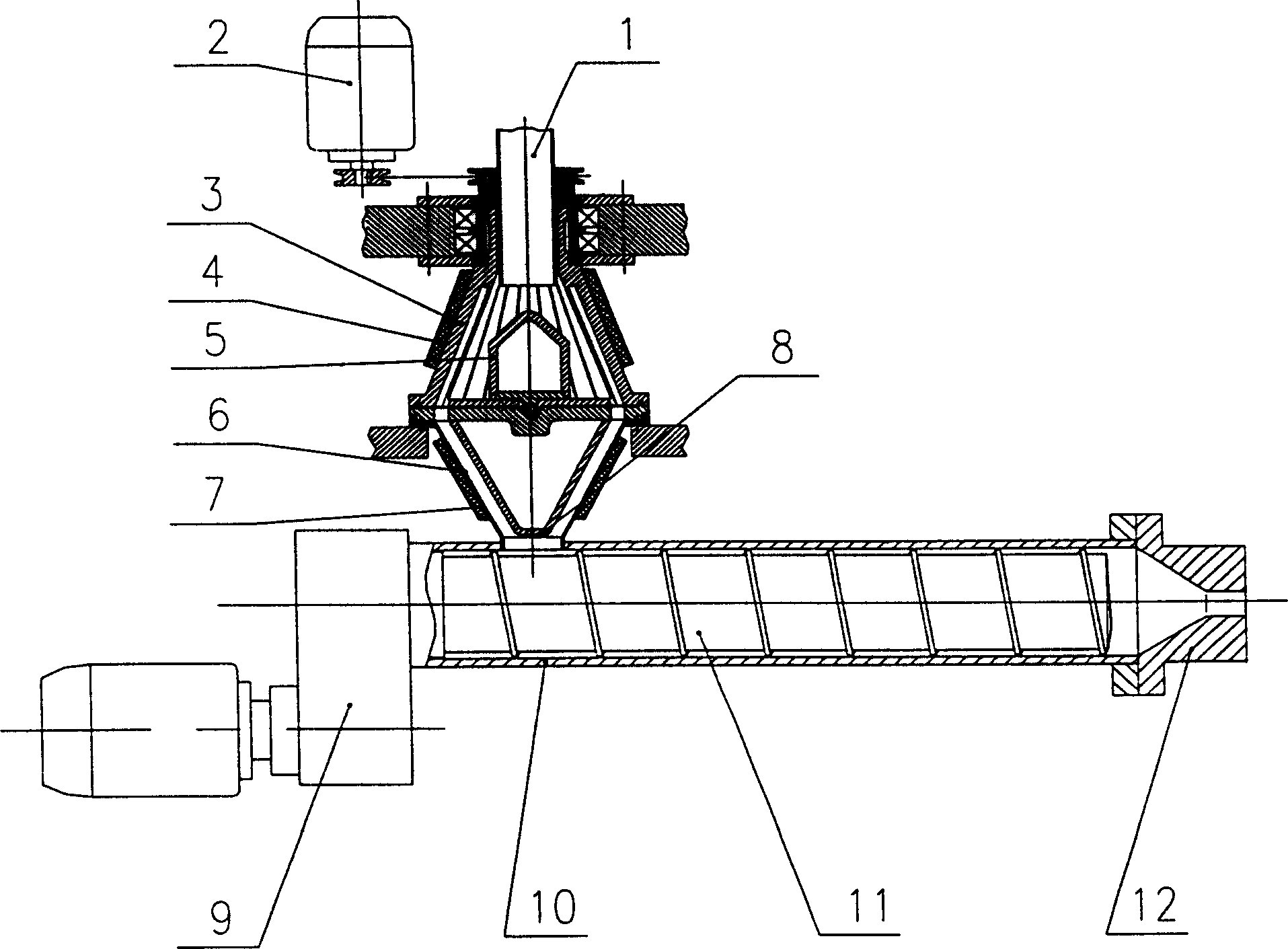

Centrifugal extruder

The centrifugal extruder has one material feeder, which is one rotating conic feeding drum and has inner core inside the drum, turned conic feeding sleeve with spiral guide slot in the inner wall, heater on the outer wall of the drum and the feeding sleeve, extruder barrel with material inlet connected to the bottom of the feeding sleeve, and fusing section corresponding to the material inlet. The material fed to the drum produces centrifugal force in the rotating conic drum and is applied with force for sliding downward along the drum wall and positive pressure from the drum wall as well as stagnation effect of the guide slot to convert the kinetic energy to the static pressure for being pushed to the fusing section, densified and fused. Therefore, the present invention has effectively lowered power consumption.

Owner:BEIJING UNIV OF CHEM TECH

Hybrid type clutch

InactiveCN106763270AImprove bindingHigh efficiency transmissionFriction clutchesHybrid typeDrive shaft

Owner:713 RES INST OF CHINA SHIPBUILDING IND CORP

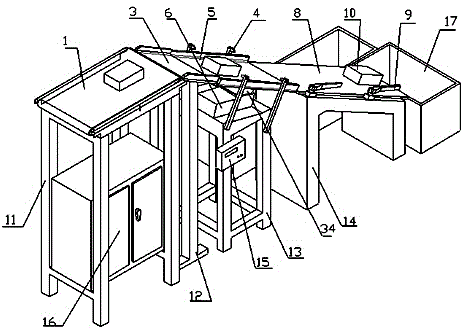

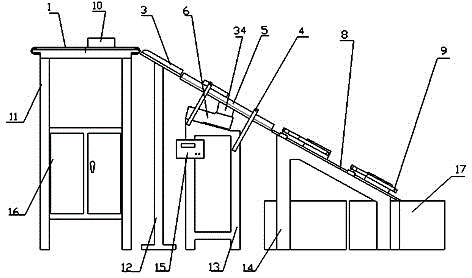

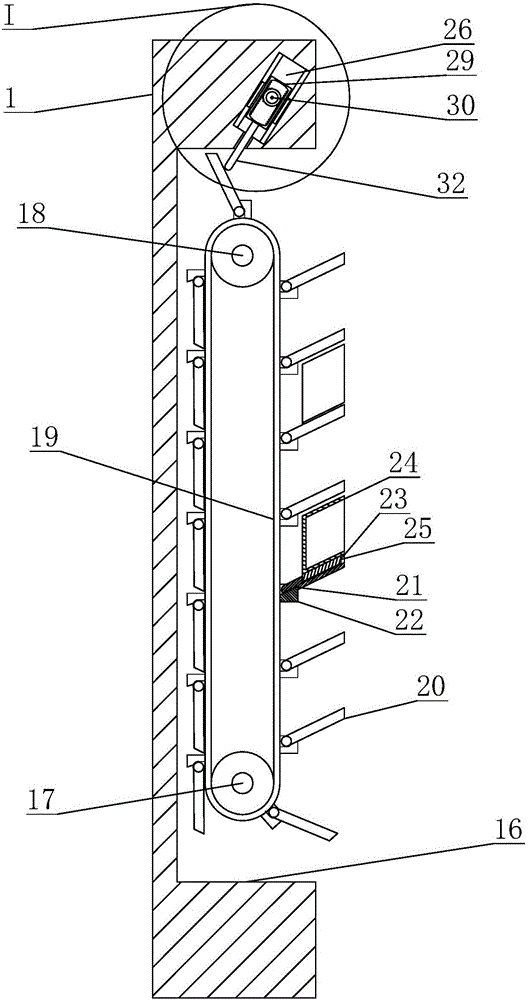

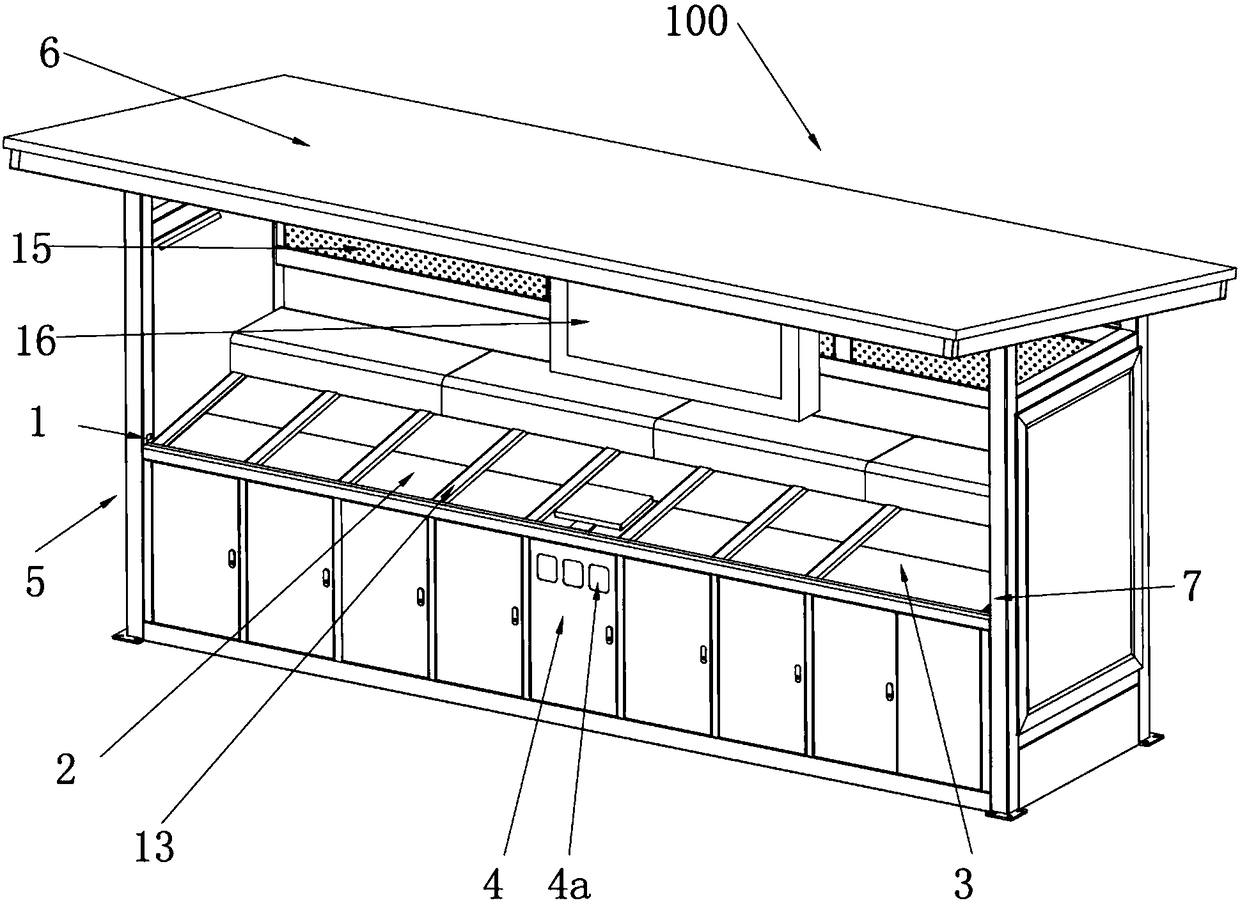

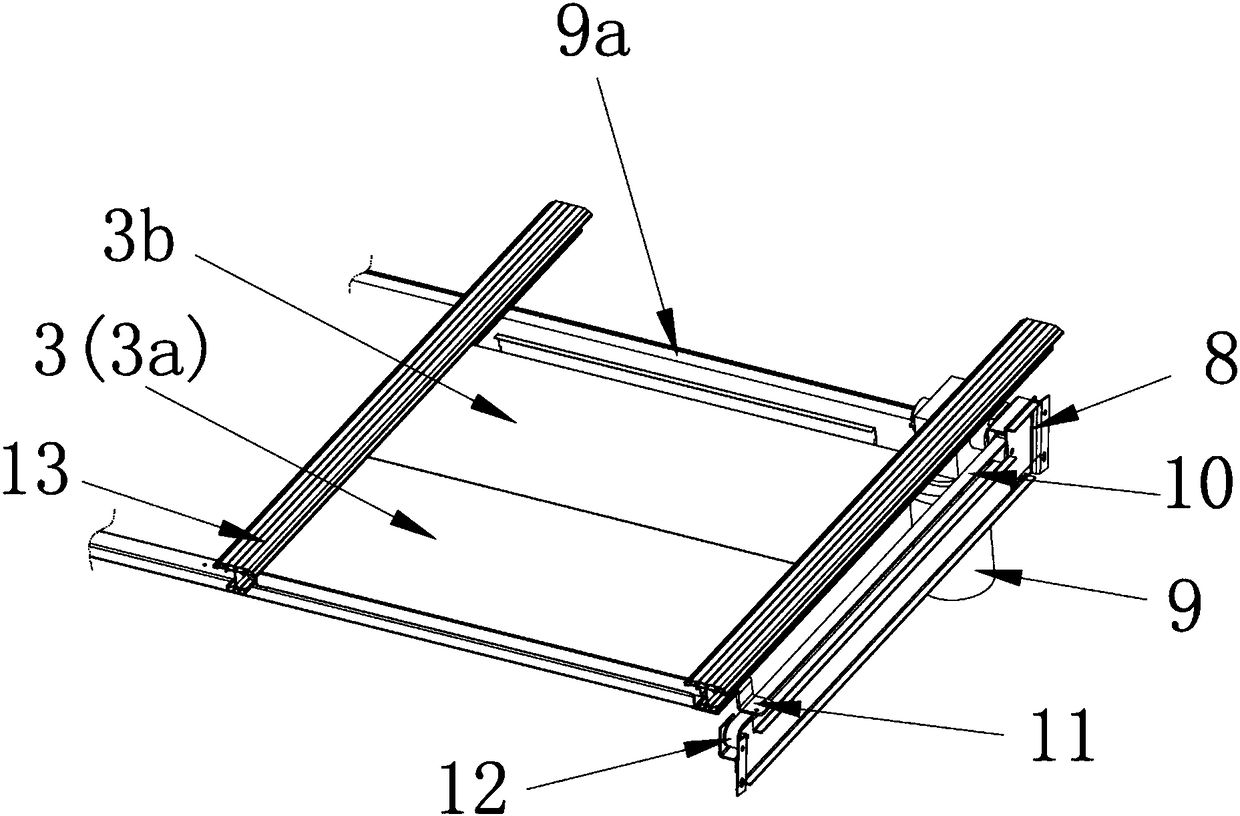

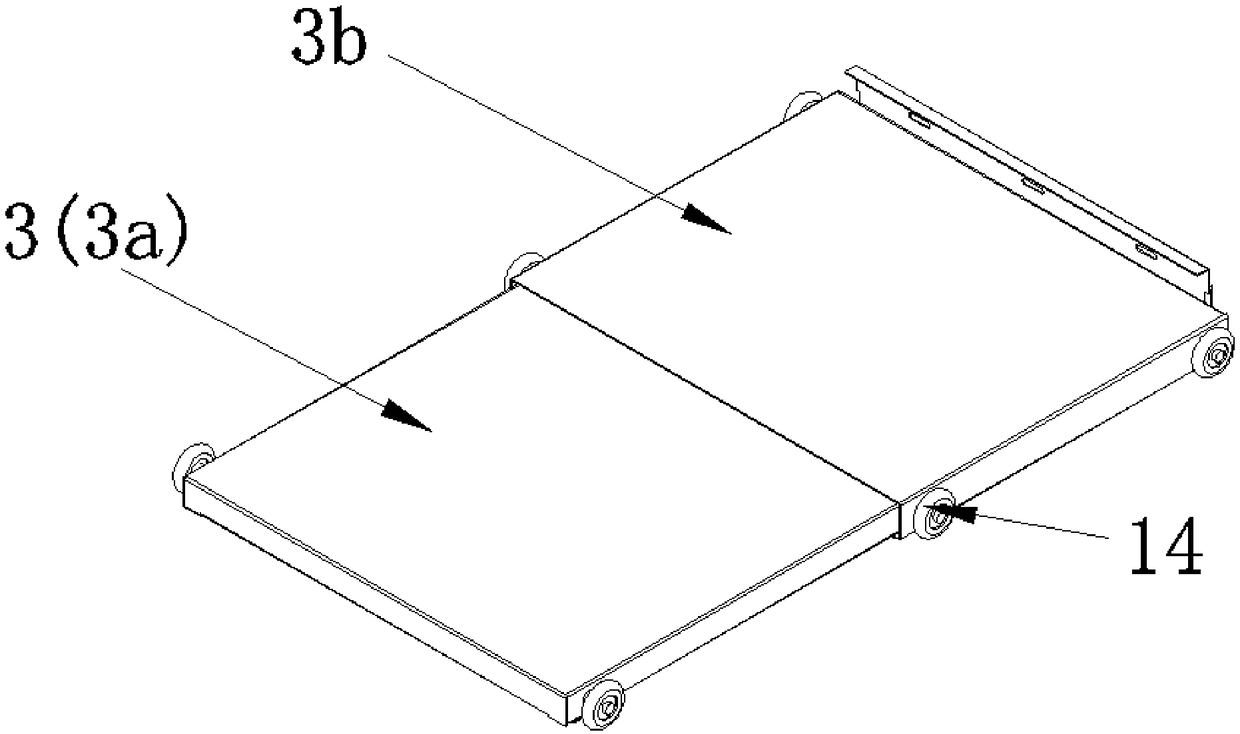

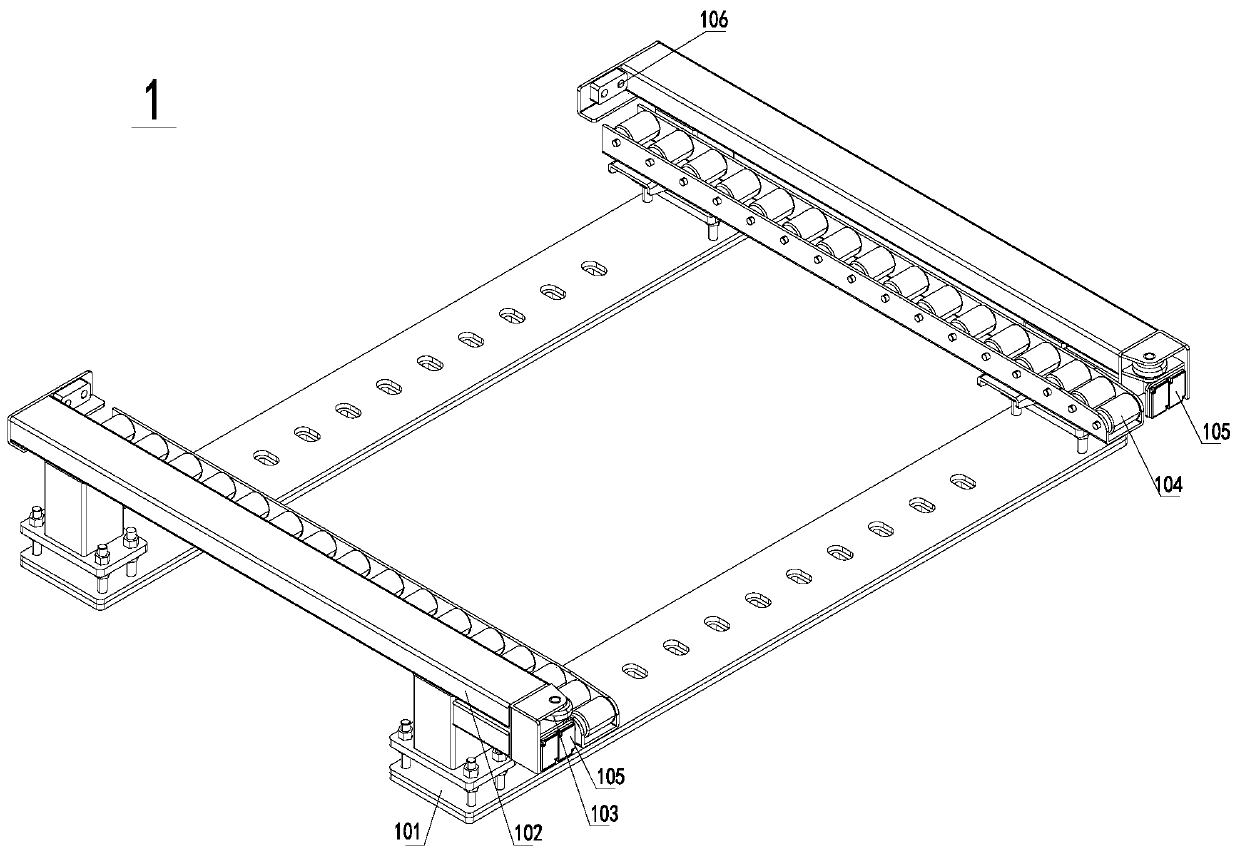

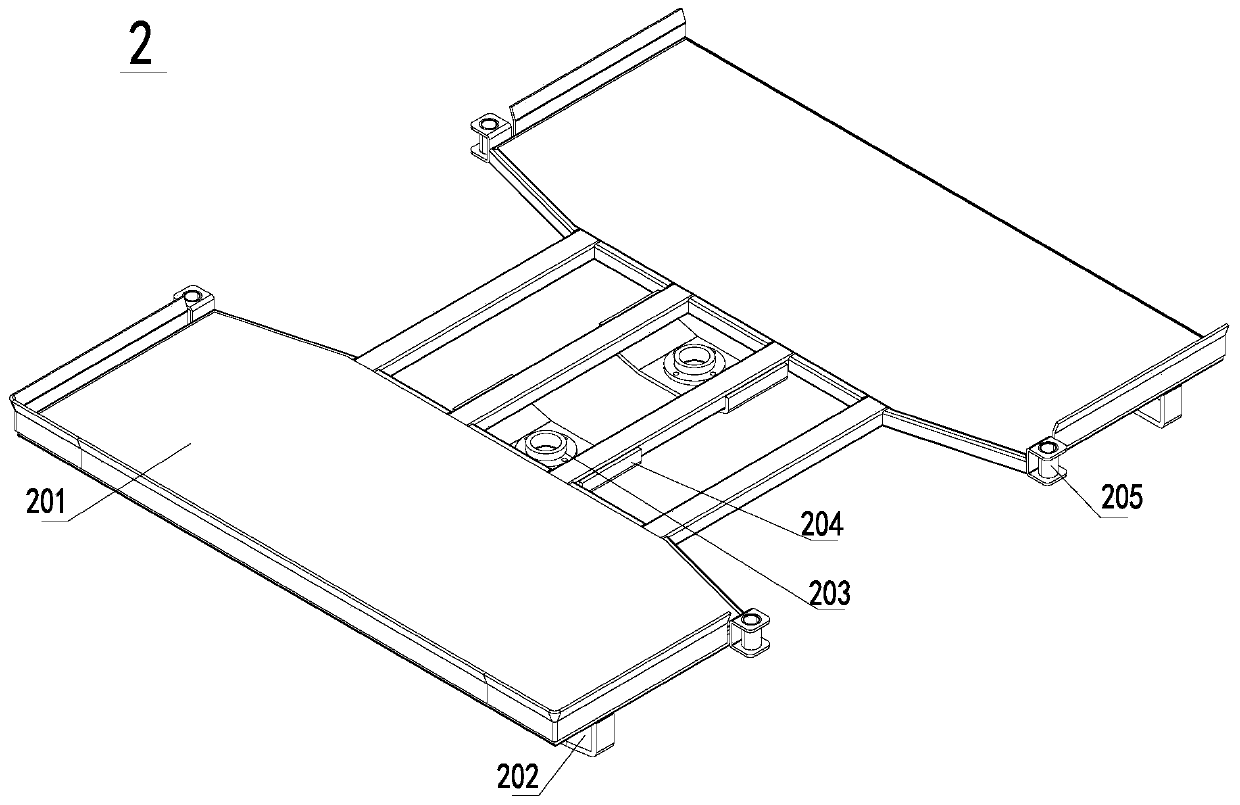

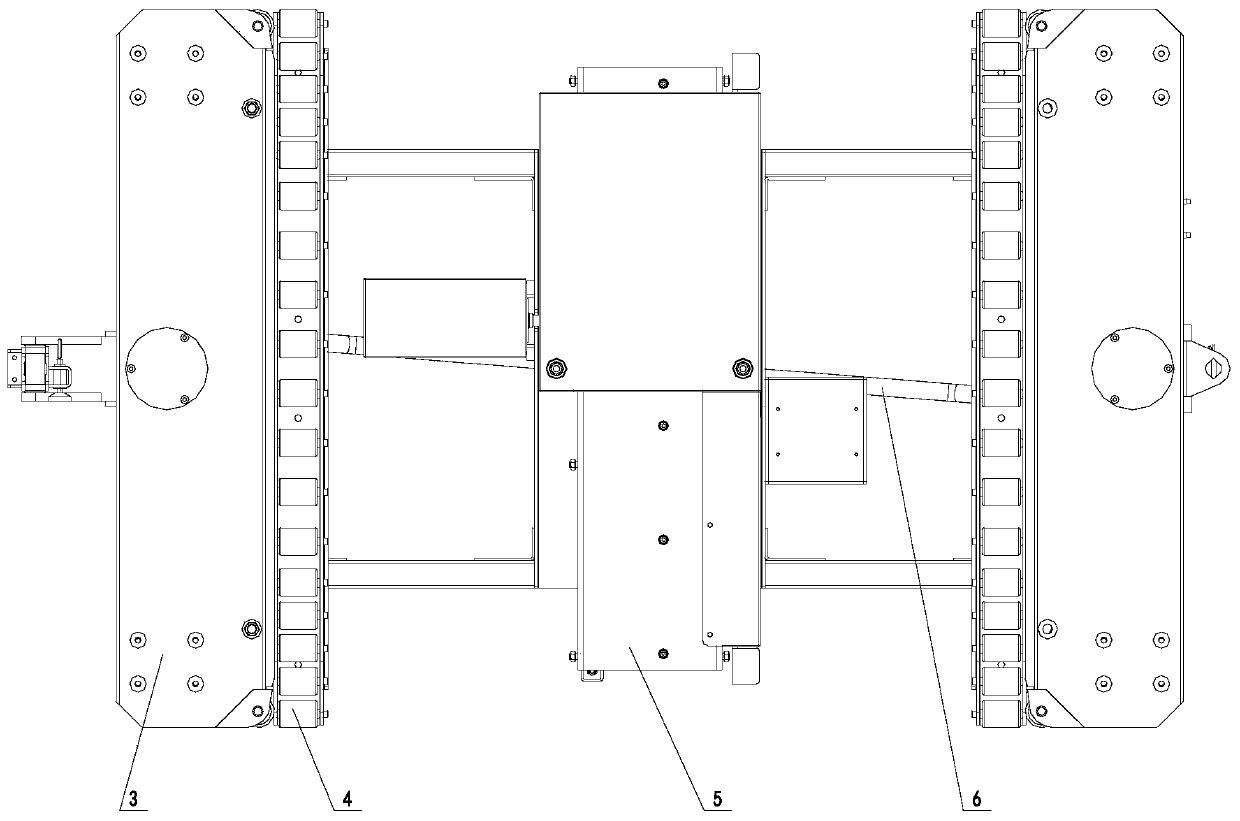

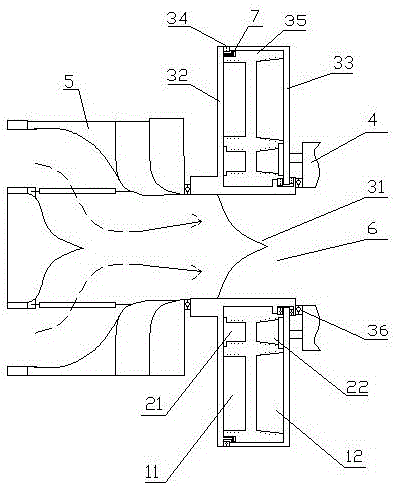

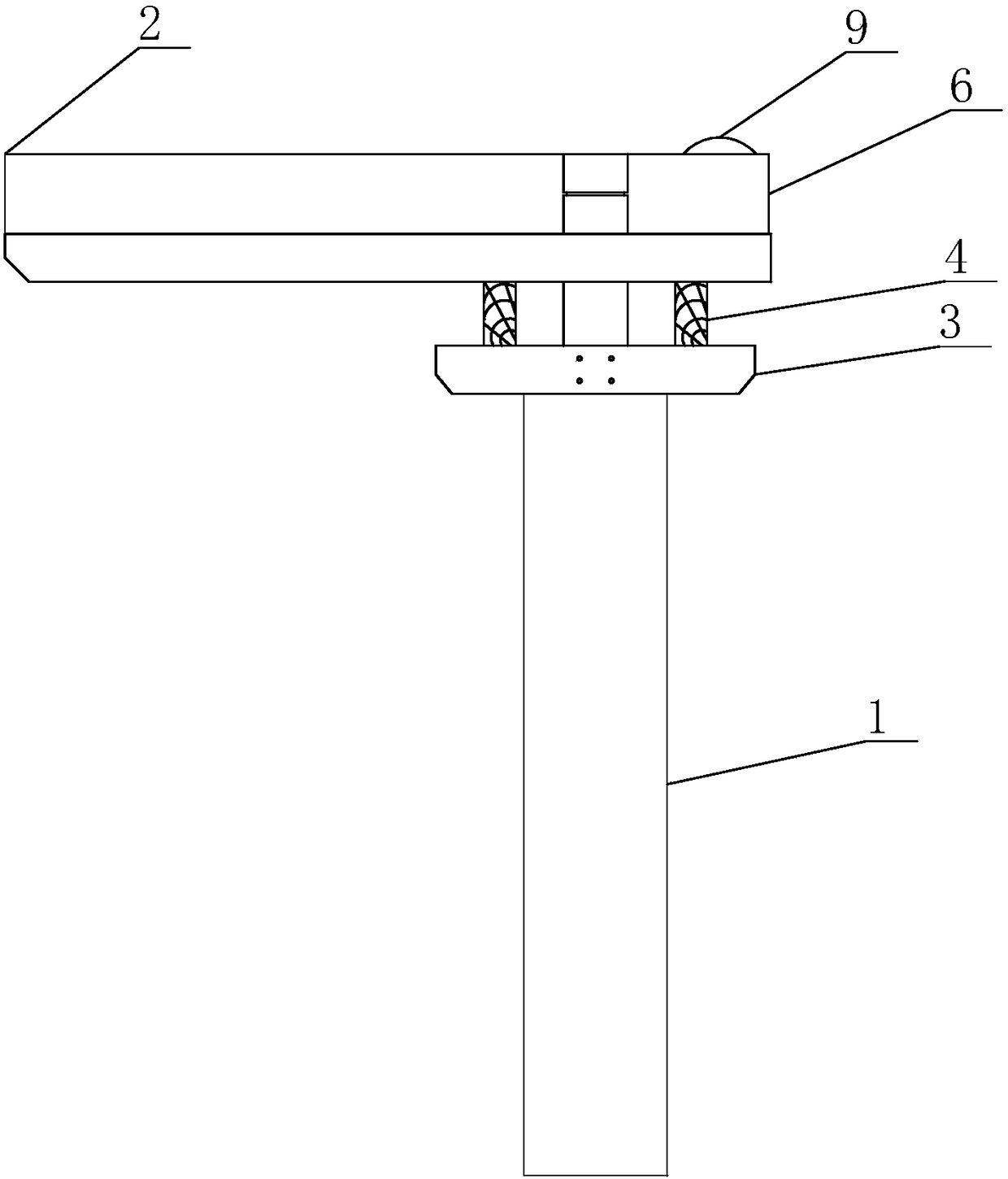

H-Frame automatic wire supply system for part transportation

PendingCN110589414AImprove flexibilityReduce frictional energyConveyor partsMechanical conveyorsCommon railEngineering

The invention belongs to the technical field of part transportation, and in particular, relates to a H-Frame automatic wire supply system for part transportation. The system comprises a wire edge platform, a tray and a H-Frame automatic connecting rod transfer car; the wire edge platform is fixed on the ground; the H-Frame automatic connecting rod transfer car comprises a main body frame, a support and guide mechanism, a taking and feeding mechanism, a common rail connecting rod mechanism and an electric control module; the support and guide mechanism is used for supporting and guiding the tray; the taking and feeding mechanism is used for taking down the tray from the wire edge platform or feeding the tray to the wire edge platform; and the common rail connecting rod mechanism is used forcontrolling a motion trajectory of the H-Frame automatic connecting rod transfer car. The system uses a traction AGV (or a tractor) for carrying with the H-Frame automatic connecting rod transfer carto supply wires, needs no manual operation in the whole wire supply process, can automatically take and feed the tray through a H-Frame, is free of fatigue through automatic wire supply, can work by24 hours, and meanwhile, is lower in cost compared with an AGV, convenient to maintain, high in compatibility and reliability and high in production efficiency.

Owner:沈阳德利沃物流装备有限公司

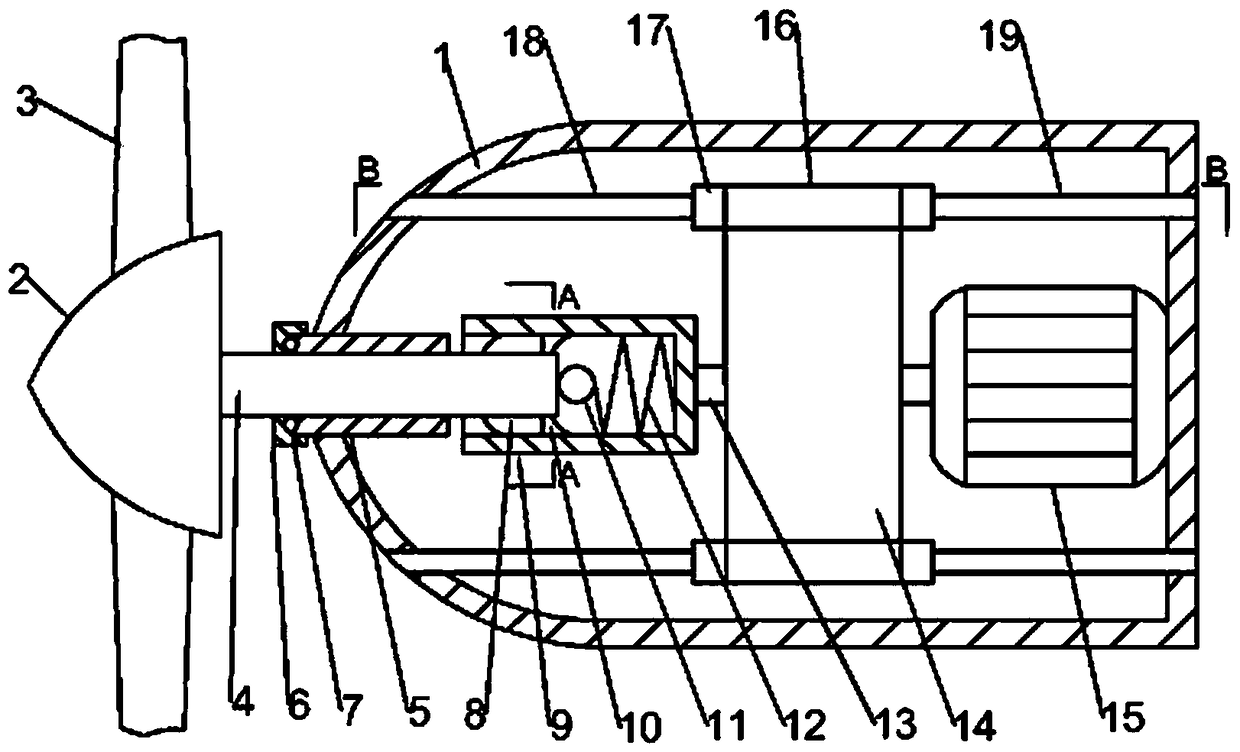

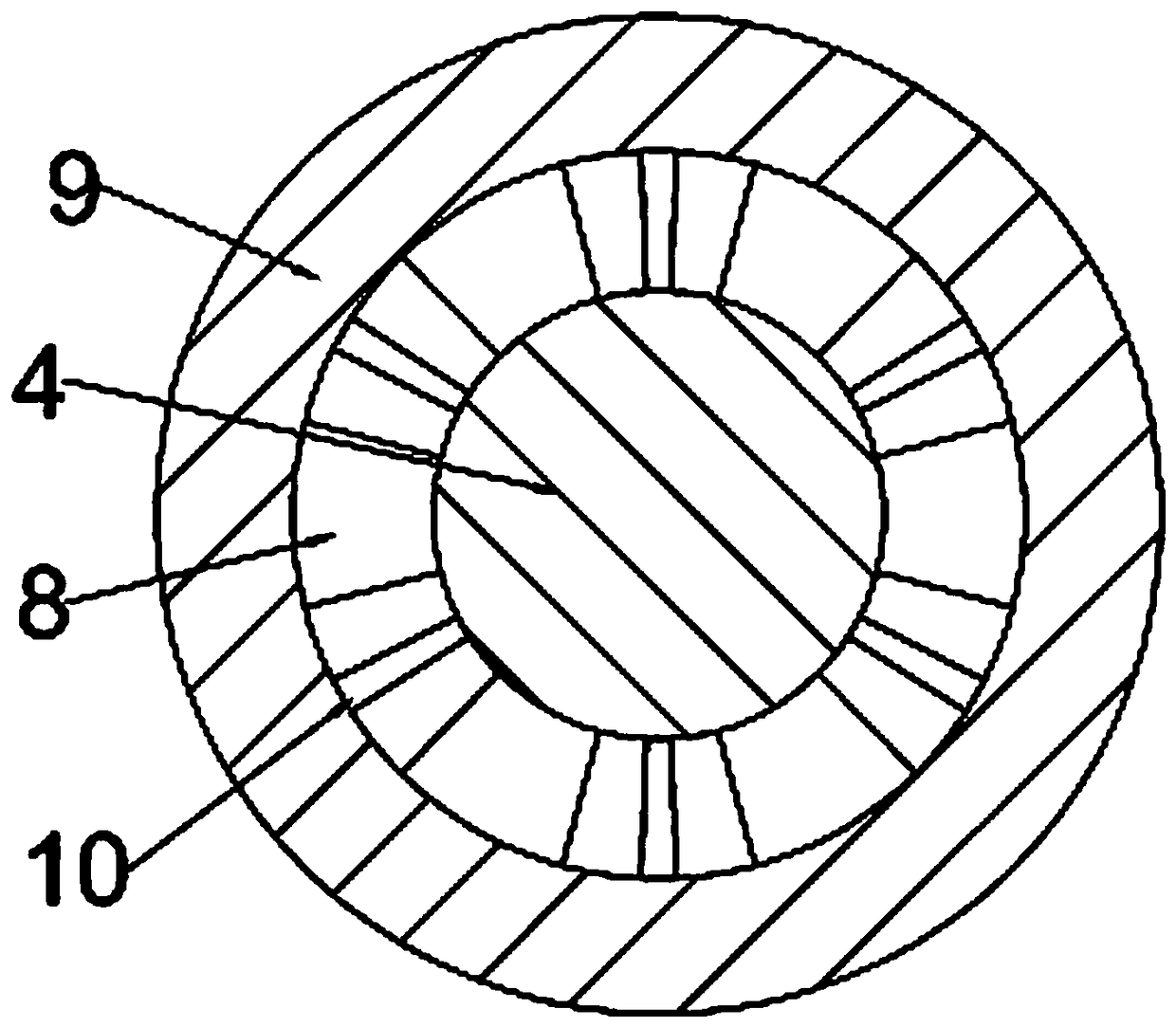

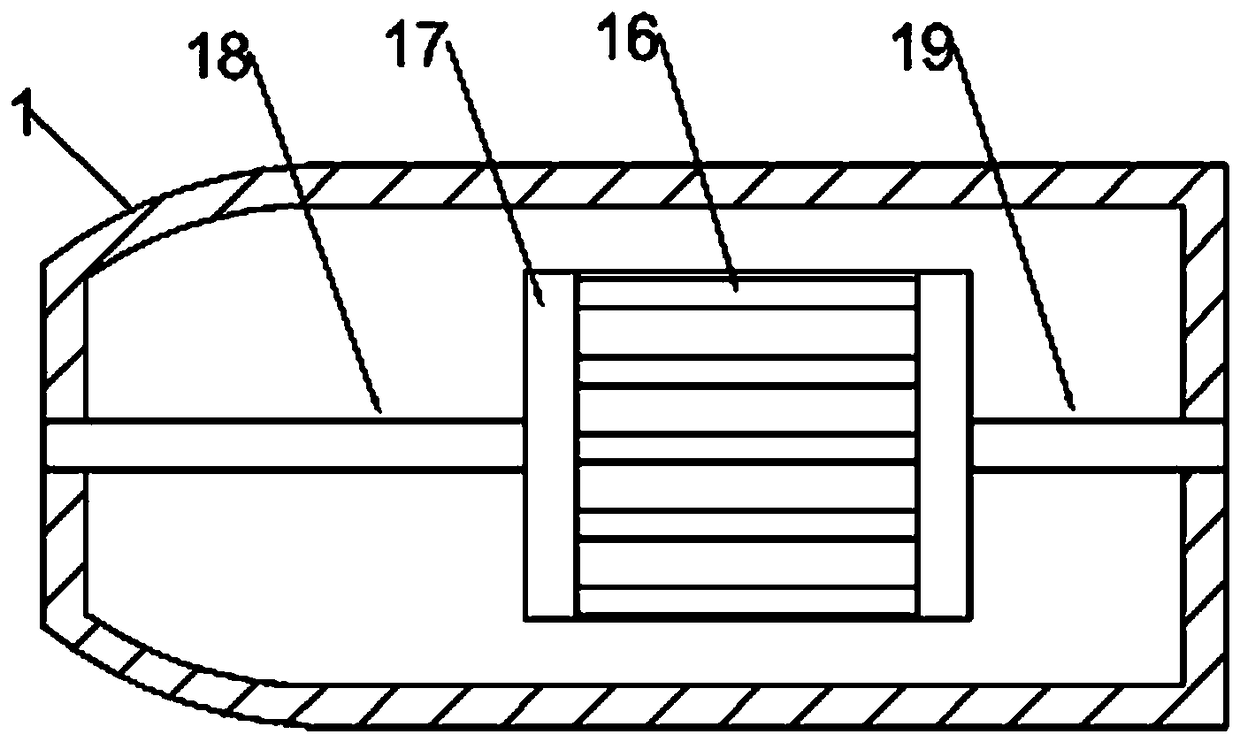

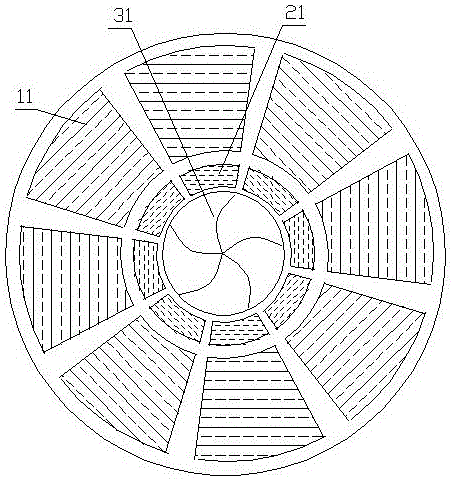

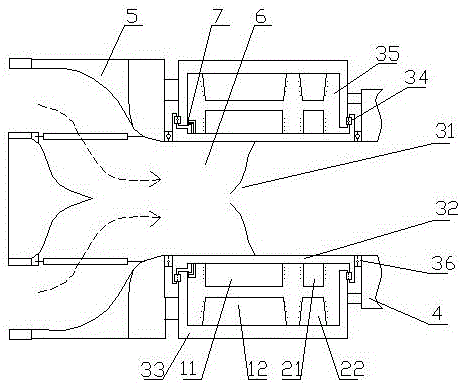

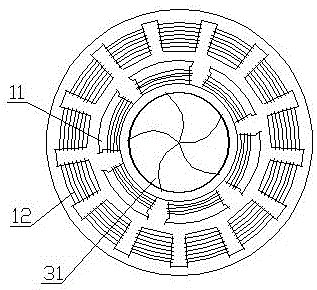

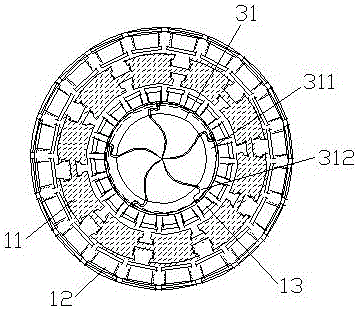

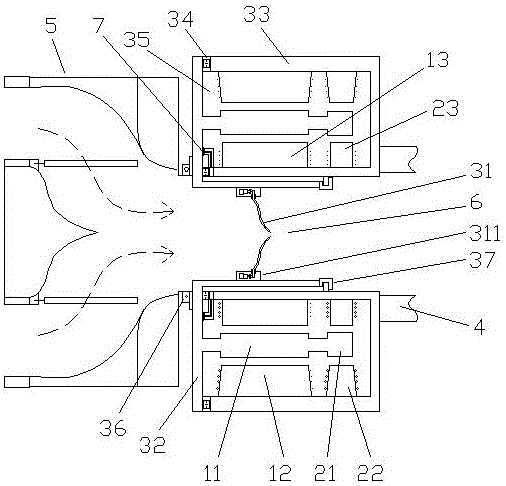

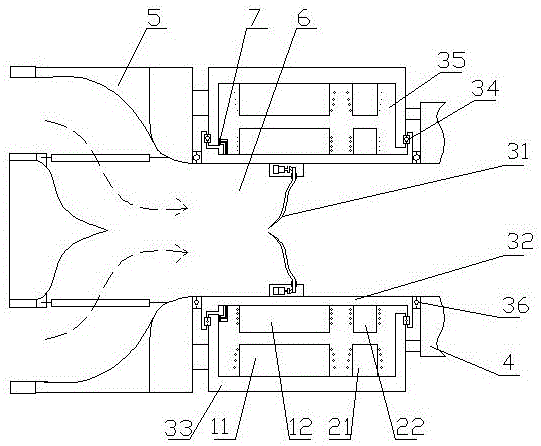

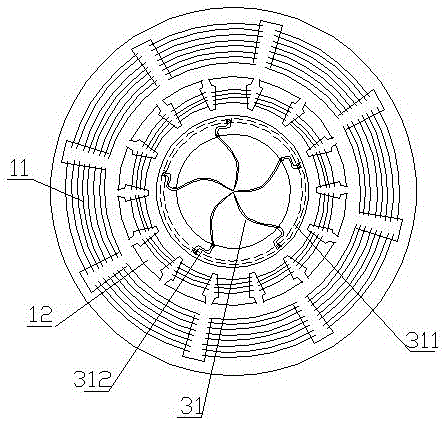

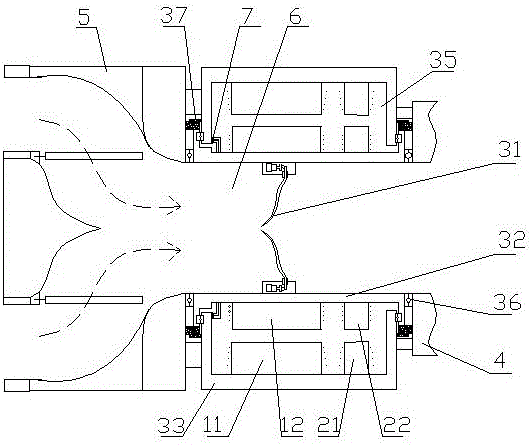

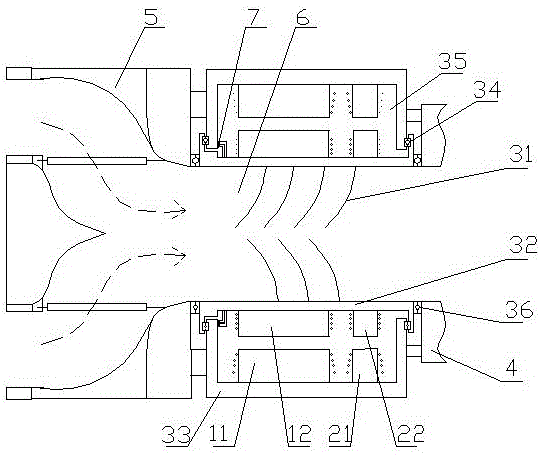

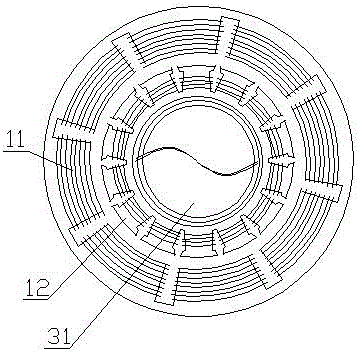

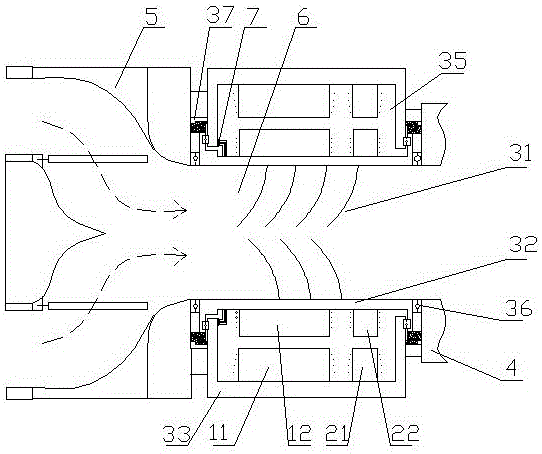

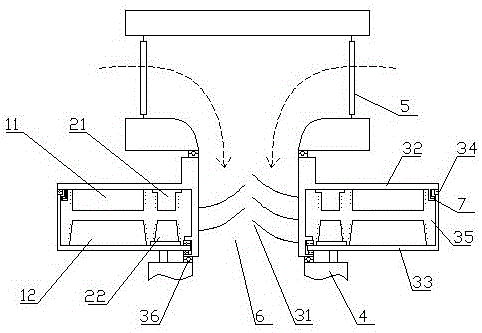

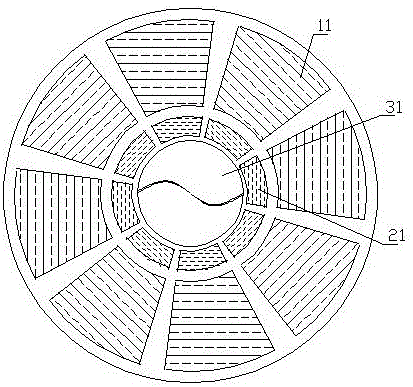

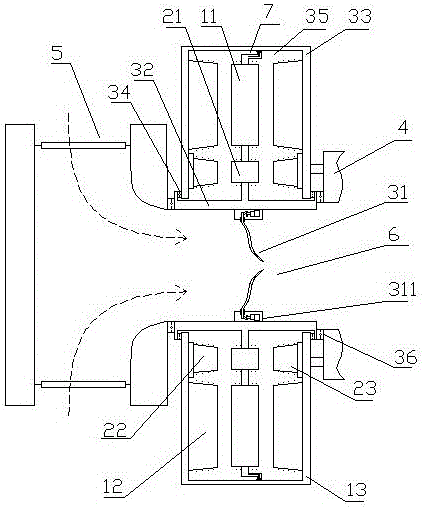

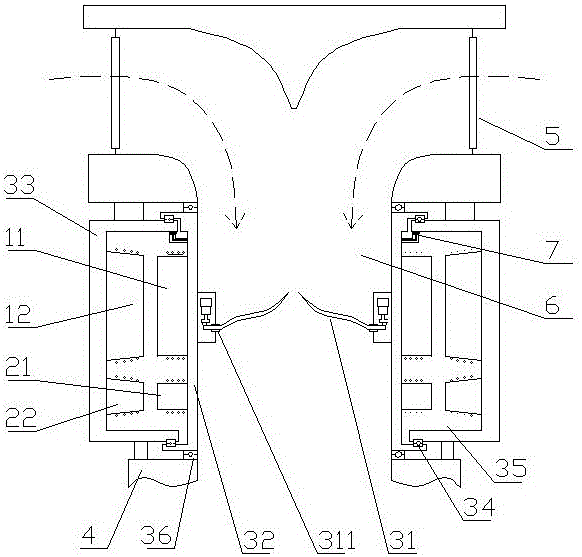

Horizontal through flat fixed paddle axial flow hydraulic generator and acting method thereof

InactiveCN106014817AReduce volumeIncrease surface areaEngine fuctionsFinal product manufactureWater flowEngineering

The invention discloses a horizontal through flat fixed paddle axial flow hydraulic generator and an acting method thereof. The horizontal through flat fixed paddle axial flow hydraulic generator comprises a power generation mechanism, an excitation mechanism, a rotating wheel mechanism, a tail water pipe, a water guide mechanism and a rotating wheel chamber; the rotating wheel mechanism includes rotating blades, a rotating front cover and a fixed back cover; the rotating blades are distributed on the inner side of the rotating front cover in a fan form; the rotating front cover and the fixed back cover are connected through a seal bearing to form a closed annular cavity; the power generation mechanism and the excitation mechanism are coaxially mounted in the annular cavity side by side inside and outside; and the water guide mechanism, the rotating wheel chamber and the tail water pipe form a water current closing channel. The horizontal through flat fixed paddle axial flow hydraulic generator is long in life, lower in construction cost and production management cost and high in water energy conversion efficiency.

Owner:郭远军

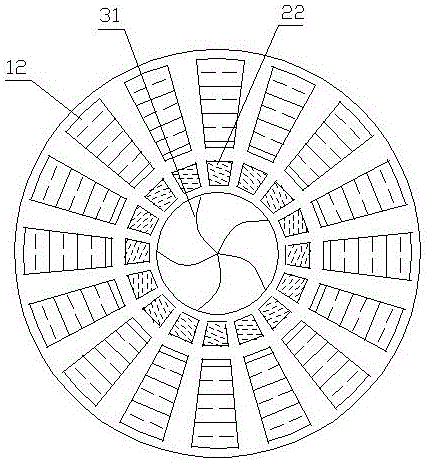

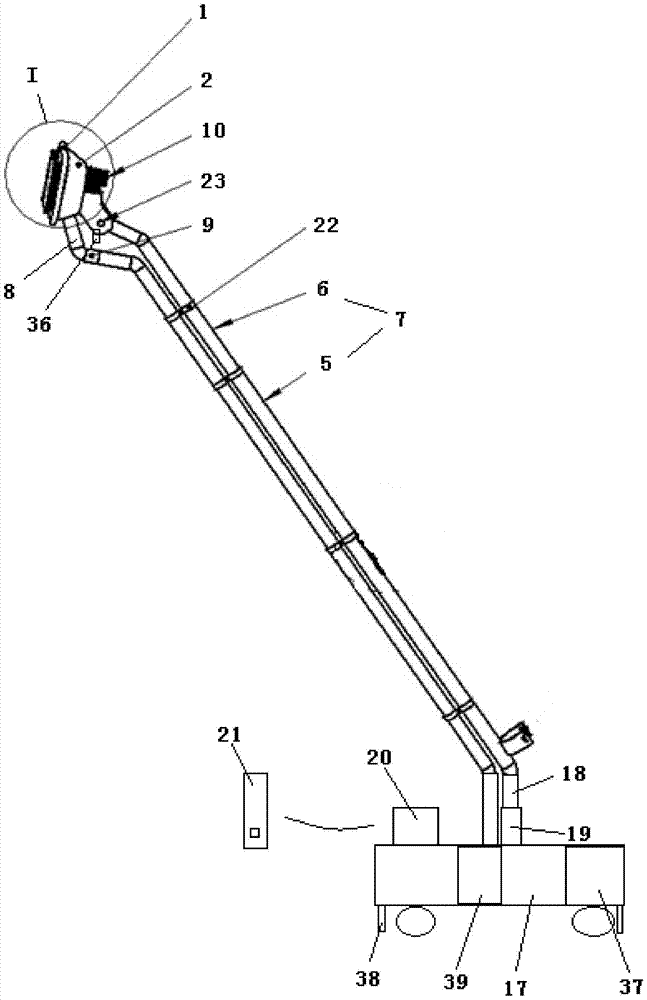

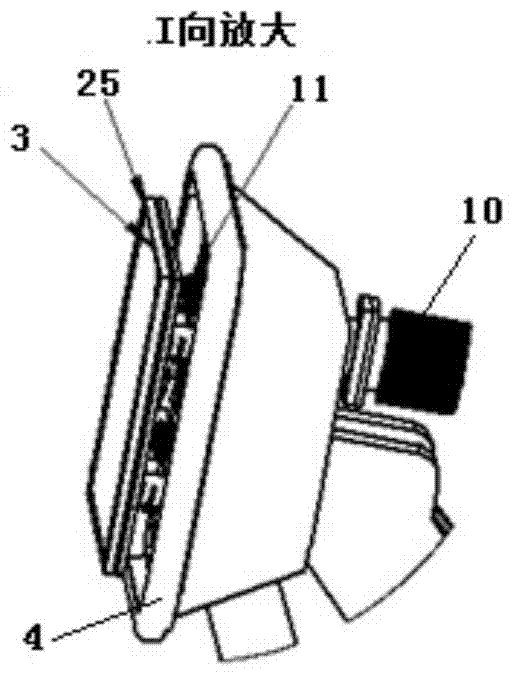

A mobile intelligent dustproof wall grinder

InactiveCN105458847BReduce labor intensityAutomate operationsGrinding drivesAutomatic grinding controlElectricitySander

The invention discloses a movable intelligent dustproof wall sanding machine and belongs to the technical field of dustproof tools. The movable intelligent dustproof wall sanding machine comprises a sander and an intelligent driving system capable of driving the sander to automatically work, wherein the sander comprises a sanding head and a sanding operation rod; the sanding head comprises a casing, a sand paper fixing plate fixed in the casing and an electric driving device used for driving the sand paper fixing plate to perform linear reciprocating motion; the electric driving device comprises a power system and a motor; and the power system comprises the motor and an eccentric disc-shaped connecting rod. According to the movable intelligent dustproof wall sanding machine, the sander is driven to automatically work by the intelligent driving system, which realizes mechanical and automatic operation, greatly reduces the labor intensity of workers, liberates the labor force, improves the working efficiency, and is conducive to guaranteeing the progress and quality of a project and reducing operation risks; and the eccentric connecting rod produces small noise and vibrations, is low in energy consumption and loss, and is conductive to prolonging the service life and reducing the using cost.

Owner:CHONGQING REAL ESTATE COLLEGE

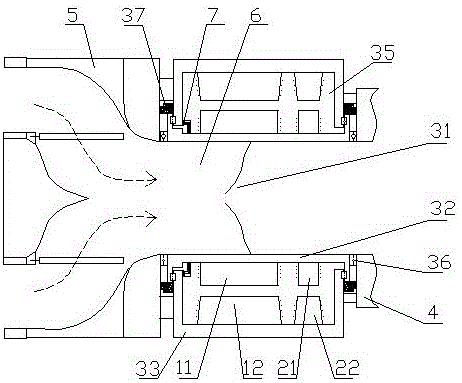

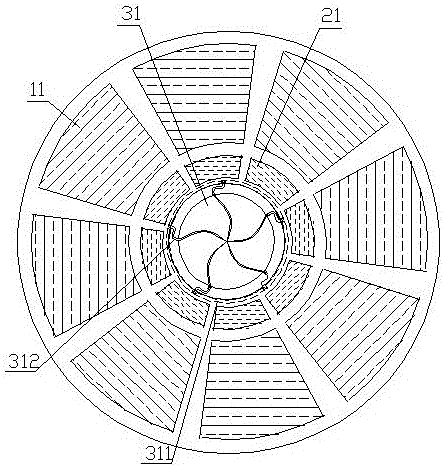

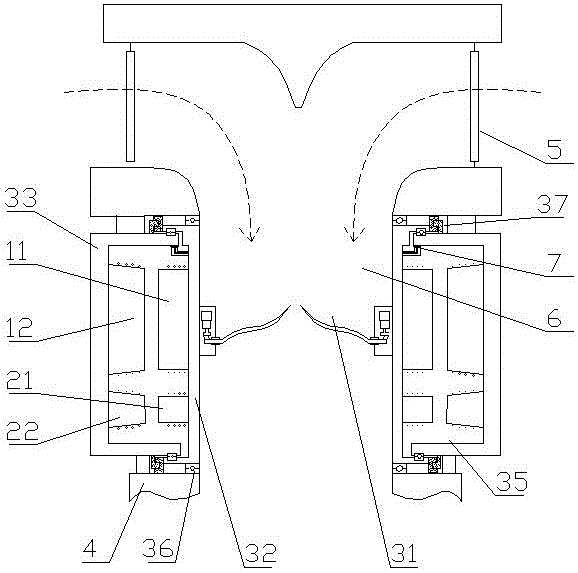

Vertical type center-through reversely-installed fixed-paddle axial flow hydraulic generator and acting method thereof

InactiveCN106014795AReduce volumeIncrease surface areaEngine fuctionsFinal product manufactureWater flowEngineering

The invention discloses a vertical type center-through reversely-installed fixed-paddle axial flow hydraulic generator and an acting method thereof. The vertical type center-through reversely-installed fixed-paddle axial flow hydraulic generator comprises a power generating mechanism, an excitation mechanism, a rotating wheel mechanism, a draft tube, a water guiding mechanism and a rotating wheel chamber. The rotating wheel mechanism comprises rotating blades, a rotary inner hood and a fixed outer hood, wherein the rotating blades are distributed on the inner side of the rotary inner hood in a sector shape, the rotary inner hood and the fixed outer hood are connected through a sealing bearing to form a sealed annular cavity, and the power generating mechanism and the excitation mechanism are coaxially mounted in the annular cavity in parallel in an up-down mode. A closed water flow channel is formed by the water guiding mechanism, the rotating wheel chamber and the draft tube. The vertical type center-through reversely-installed fixed-paddle axial flow hydraulic generator is long in service life, low in building cost and production management cost and high in water energy converting efficiency.

Owner:郭远军

Horizontal type center-through forward-installed fixed-paddle axial flow hydraulic generator and acting method thereof

InactiveCN106014800AReduce volumeIncrease surface areaEngine fuctionsFinal product manufactureWater flowMechanical engineering

The invention discloses a horizontal type center-through forward-installed fixed-paddle axial flow hydraulic generator and an acting method thereof. The horizontal type center-through forward-installed fixed-paddle axial flow hydraulic generator comprises a power generating mechanism, an excitation mechanism, a rotating wheel mechanism, a draft tube, a water guiding mechanism and a rotating wheel chamber. The rotating wheel mechanism comprises rotating blades, a rotary inner hood and a fixed outer hood, wherein the rotating blades are distributed on the inner side of the rotary inner hood in a sector shape, the rotary inner hood and the fixed outer hood are connected through a sealing bearing to form a sealed annular cavity, and the power generating mechanism and the excitation mechanism are coaxially mounted in the annular cavity in parallel in an up-down mode. A closed water flow channel is formed by the water guiding mechanism, the rotating wheel chamber and the draft tube. The horizontal type center-through forward-installed fixed-paddle axial flow hydraulic generator is long in service life, low in building cost and production management cost and high in water energy converting efficiency.

Owner:郭远军

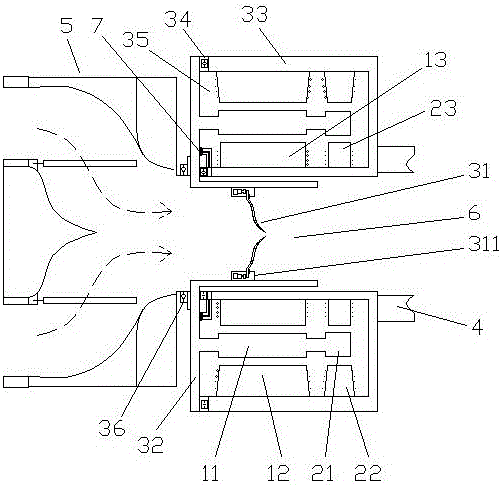

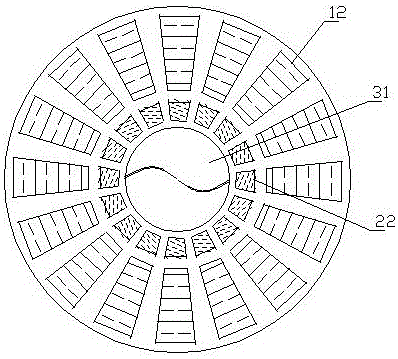

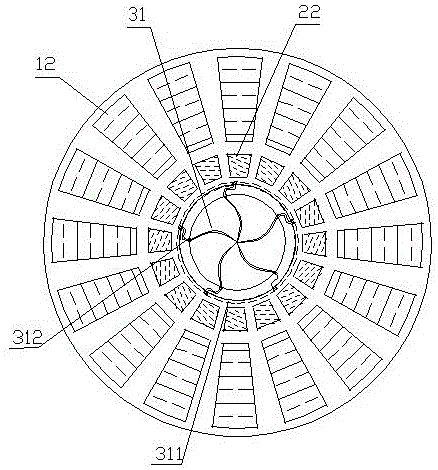

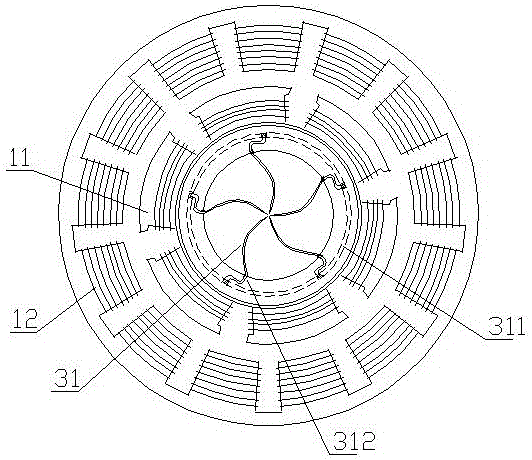

Horizontal type annular efficient excitation adjustable-pitch axial flow hydraulic generator and acting method

InactiveCN106014809AReduce volumeIncrease surface areaFinal product manufactureHydro energy generationWater flowEngineering

The invention discloses a horizontal type annular efficient excitation adjustable-pitch axial flow hydraulic generator and an acting method. The horizontal type annular efficient excitation adjustable-pitch axial flow hydraulic generator comprises a power generating mechanism, an excitation mechanism, a runner mechanism, an exhaust water pipe, a water guiding mechanism and a runner chamber. The runner mechanism comprises rotary blades, an annular rotary cover and an annular fixed cover. The rotary blades are distributed on the inner side of the annular rotary cover in a fan-shaped mode. The annular rotary cover and the annular fixed cover are connected through a sealing bearing to form a sealed annular cavity. The power generating mechanism and the excitation mechanism are coaxially installed in the annular cavity in a front-back mode side by side. A sealed water flow channel is formed by the water guiding mechanism, the runner chamber and the exhaust water pipe. The horizontal type annular efficient excitation adjustable-pitch axial flow hydraulic generator is long in service life, low in construction cost and production management cost and high in hydraulic energy conversion efficiency.

Owner:郭远军

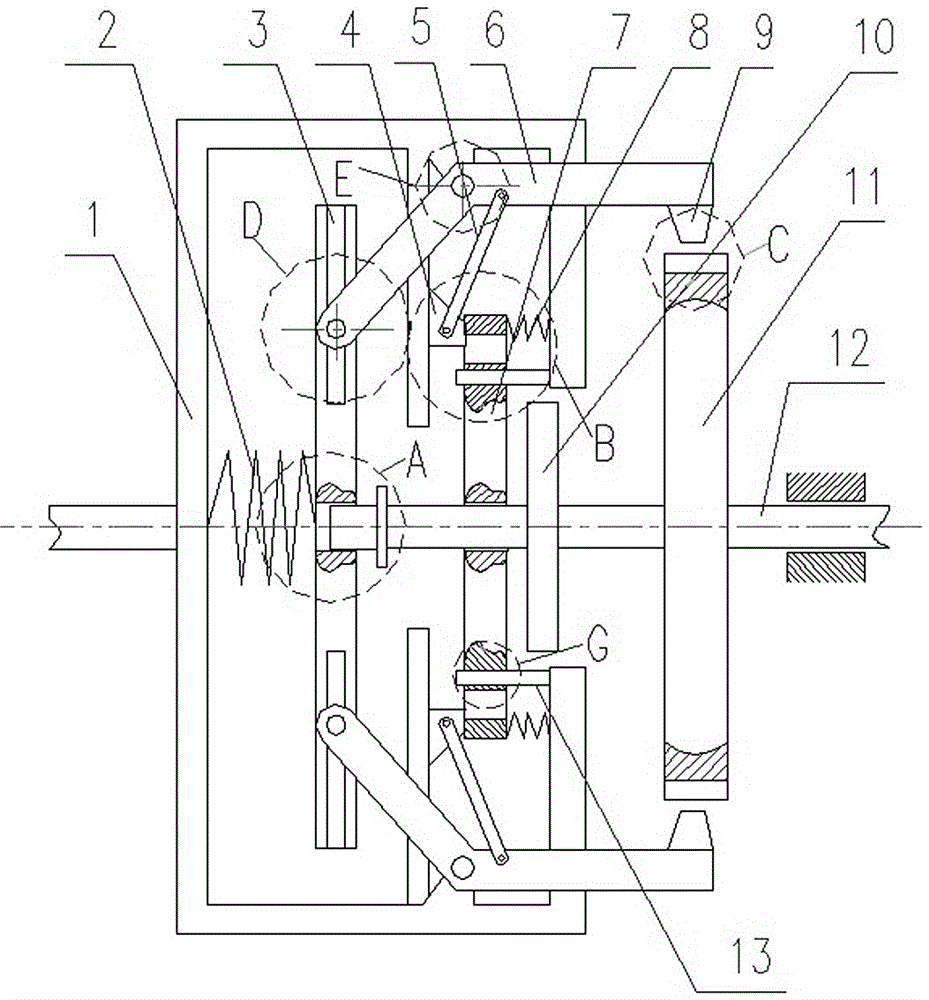

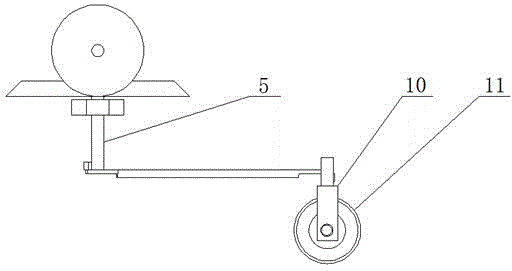

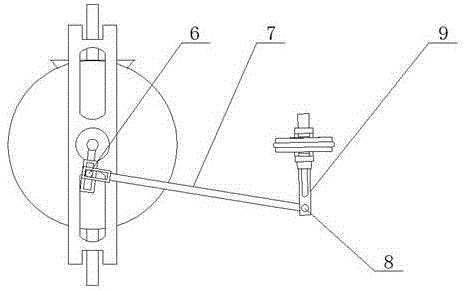

Carbon-free trolley steering gear

InactiveCN104527887AReduce frictional energyReduce precisionCyclesToy gearsEngineeringEnergy consumption

The invention relates to a carbon-free trolley steering gear, a fine adjustment long rod is connected with a cross rod through a fine adjustment nut, the cross rod is fixed on a front wheel support, the fine adjustment nut, the fine adjustment long rod, a rotational nut and the cross rod constitute a crank connecting link displacement fine adjustment system, the carbon-free trolley steering gear adopts a crank connecting link mechanism so as to realize trolley steering fine adjustment, by changing the relative positions of the fine adjustment nut and a fine adjustment crank rotation center shaft, the position of the fine adjustment nut, which is on the fine adjustment long rod, realizes the obstacle crossing requirement for different intervals within 700 millimeters to 1300 millimeters, as the crank connecting link mechanism does not have a sliding pair of a sine mechanism, the energy consumption caused by friction is reduced greatly, simultaneously, the precision prescribed is relatively lowered, and thus batch production can be realized.

Owner:EAST CHINA JIAOTONG UNIVERSITY

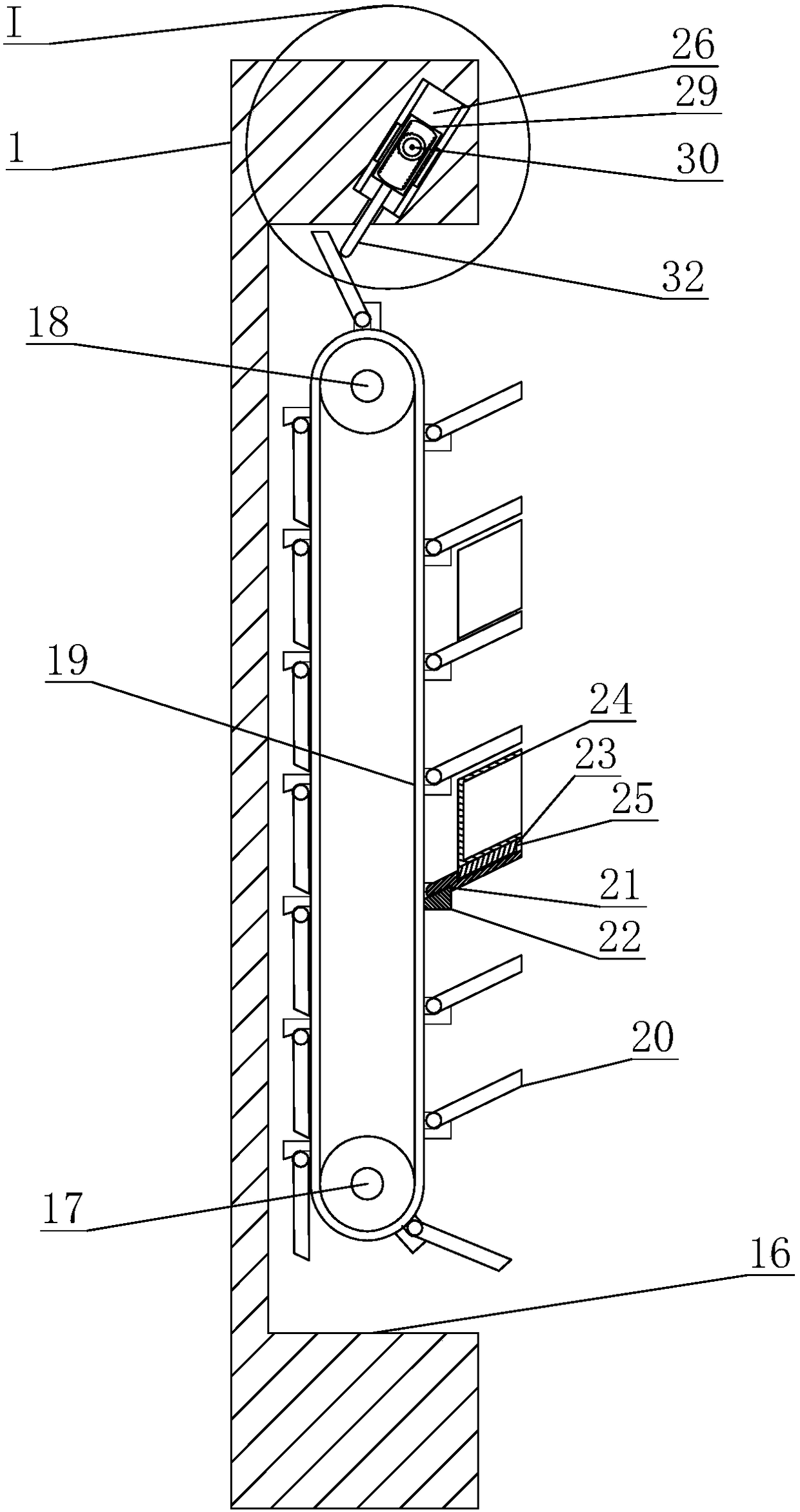

Integrated landscape piece flower stand

InactiveCN105815149BLayout diversificationExquisite local shapeSpecial buildingCultivating equipmentsLandscape designEngineering

The invention discloses an integrated landscape piece flower stand, which mainly relates to the field of landscape design. Including the flower wall frame and the shed frame, the shed is equipped with a rain awning, and the awning can be rolled into the cylinder at one end of the shed, and a plurality of bar-shaped grooves are arranged on the flower wall frame, and the bar-shaped groove is equipped with an up and down circular rotation The drive belt is provided with a flashboard, and a flower box is movably plugged on the flashboard. The beneficial effect of the present invention is that it adopts the combination design of the flower stand and the design of the vertical plant modeling wall, which can not only provide rest facilities for tourists, but also create green plant landscapes from multiple angles in the top space and vertical space, and is easy to assemble , and has the function of blocking rain and snow, making the overall layout of the garden more diversified and the local shape more refined.

Owner:SHANDONG UNIV OF SCI & TECH

Horizontal through reverse rotating paddle axial flow hydraulic generator and acting method thereof

InactiveCN106014815AReduce volumeIncrease surface areaFinal product manufactureEngine fuctionsWater flowEngineering

The invention discloses a horizontal through reverse rotating paddle axial flow hydraulic generator and an acting method thereof. The horizontal through reverse rotating paddle axial flow hydraulic generator comprises a power generation mechanism, an excitation mechanism, a rotating wheel mechanism, a tail water pipe, a water guide mechanism and a rotating wheel chamber; the rotating wheel mechanism includes rotating blades, a rotating inner cover and a fixed outer cover; the rotating blades are distributed on the inner side of the rotating inner cover in a fan form; the rotating inner cover and the fixed outer cover are connected through a seal bearing to form a closed annular cavity; the power generation mechanism and the excitation mechanism are coaxially mounted in the annular cavity side by side up and down; and the water guide mechanism, the rotating wheel chamber and the tail water pipe form a water current closing channel. The horizontal through reverse rotating paddle axial flow hydraulic generator is long in life, lower in construction cost and production management cost and high in water energy conversion efficiency.

Owner:郭远军

Horizontal through reverse spiral axial flow hydraulic generator and acting method thereof

PendingCN106014816AReduce volumeIncrease surface areaEngine fuctionsHydro energy generationSpiral bladeWater flow

The invention discloses a horizontal through reverse spiral axial flow hydraulic generator and an acting method thereof. The horizontal through reverse spiral axial flow hydraulic generator comprises a power generation mechanism, an excitation mechanism, a rotating wheel mechanism, a tail water pipe, a water guide mechanism and a rotating wheel chamber; the rotating wheel mechanism includes spiral blades, a rotating inner cover and a fixed outer cover; the spiral blades are spirally distributed on the inner side of the rotating inner cover; the rotating inner cover and the fixed outer cover are connected through a seal bearing to form a closed annular cavity; the power generation mechanism and the excitation mechanism are coaxially mounted in the annular cavity side by side up and down; and the water guide mechanism, the rotating wheel chamber and the tail water pipe form a water current closing channel. The horizontal through reverse spiral axial flow hydraulic generator is long in life, lower in construction cost and production management cost and high in water energy conversion efficiency.

Owner:郭远军

Vertical through flush helical axial flow-type hydrogenerator and working method thereof

InactiveCN106026519AReduce volumeIncrease surface areaFinal product manufactureHydro energy generationWater flowEngineering

The invention discloses a vertical through flush helical axial flow-type hydrogenerator and a working method thereof. The vertical through flush helical axial flow-type hydrogenerator comprises a power generation mechanism, an excitation mechanism, a runner mechanism, an exhaust water pipe, a water guide mechanism and a runner chamber, wherein the runner mechanism comprises helical fins, a rotary upper cover and a fixed lower cover; the helical fins are helically distributed on the inner side of the rotary upper cover; the rotary upper cover and the fixed lower cover are connected through a seal bearing to form an enclosed annular cavity; the excitation mechanism and the power generation mechanism are internally and externally arranged in the annular cavity coaxially in parallel; and the water guide mechanism, the runner chamber and the exhaust water pipe form a flow blocking channel. The vertical through flush helical axial flow-type hydrogenerator is long in lifetime; the construction cost and the production management cost are relatively low; and the water energy conversion efficiency is high.

Owner:郭远军

Horizontal type flush efficient excitation adjustable-pitch axial flow hydraulic generator and acting method thereof

InactiveCN106014828AThermal Rate BlockGood cooling effectFinal product manufactureHydro energy generationEnergy conversion efficiencyEngineering

The invention discloses a horizontal type flush efficient excitation adjustable-pitch axial flow hydraulic generator and an acting method thereof. The horizontal type flush efficient excitation adjustable-pitch axial flow hydraulic generator comprises a power generating mechanism, an excitation mechanism, a runner mechanism, an exhaust water pipe, a water guiding mechanism and a runner chamber. The runner mechanism comprises rotary blades, a rotary inner cover and a fixed outer cover. The rotary blades are distributed on the inner side of the rotary inner cover in a fan-shaped mode. The rotary inner cover and the fixed outer cover are connected through a sealing bearing to form a sealed annular cavity. The excitation mechanism and the power generating mechanism are coaxially installed in the annular cavity in an inside-outside mode side by side. A sealed water flow channel is formed by the water guiding mechanism, the runner chamber and the exhaust water pipe. The horizontal type flush efficient excitation adjustable-pitch axial flow hydraulic generator is long in service life, low in construction cost and production management cost and high in hydraulic energy conversion efficiency.

Owner:郭远军

hybrid clutch

InactiveCN106763270BImprove bindingHigh efficiency transmissionFriction clutchesHybrid typeDrive shaft

The invention relates to a hybrid type clutch, and belongs to the field of mechanical design. The hybrid type clutch comprises a driven disk connected with a driven shaft, and further comprises a driving friction combination piece and a rigid combination piece which are connected with a driving shaft, wherein a driven friction combination piece and a driven rigid combination piece are arranged in the driven disk; under an initial state, the driving friction combination piece on the driving shaft is combined with the driven friction combination piece in the driven disk; and when rotating at high speed, the driving shaft is moved to enable the rigid combination piece to be combined with the driven rigid combination piece and enable the driving friction combination piece to be separated from the driven friction combination piece. Compared with the prior art, the hybrid type clutch aims to realize steady combination and efficient transmission of the clutch; the steady combination is realized through friction at the combination front end of the clutch; and when the driving shaft rotates at the high speed, the clutch carries out rigid combination and friction combination piece separation to realize efficient transmission, so that the friction energy consumption and friction heat are substantially reduced.

Owner:713 RES INST OF CHINA SHIPBUILDING IND CORP

Vertical type center-through forward-installed rotary-paddle axial flow hydraulic generator and acting method thereof

InactiveCN106014797AReduce volumeIncrease surface areaEngine fuctionsFinal product manufactureWater flowMechanical engineering

The invention discloses a vertical type center-through forward-installed rotary-paddle axial flow hydraulic generator and an acting method thereof. The vertical type center-through forward-installed rotary-paddle axial flow hydraulic generator comprises a power generating mechanism, an excitation mechanism, a rotating wheel mechanism, a draft tube, a water guiding mechanism and a rotating wheel chamber. The rotating wheel mechanism comprises rotating blades, a rotary inner hood and a fixed outer hood, wherein the rotating blades are distributed on the inner side of the rotary inner hood in a sector shape, the rotary inner hood and the fixed outer hood are connected through a sealing bearing to form a sealed annular cavity, and the power generating mechanism and the excitation mechanism are coaxially mounted in the annular cavity in parallel in an up-down mode. A closed water flow channel is formed by the water guiding mechanism, the rotating wheel chamber and the draft tube. The vertical type center-through forward-installed rotary-paddle axial flow hydraulic generator is long in service life, low in building cost and production management cost and high in water energy converting efficiency.

Owner:郭远军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com