Electronic sliding table

A sliding table, electronic technology, applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of high noise, complicated design, etc., to achieve low frictional energy consumption, ingenious and simple design, low frictional resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

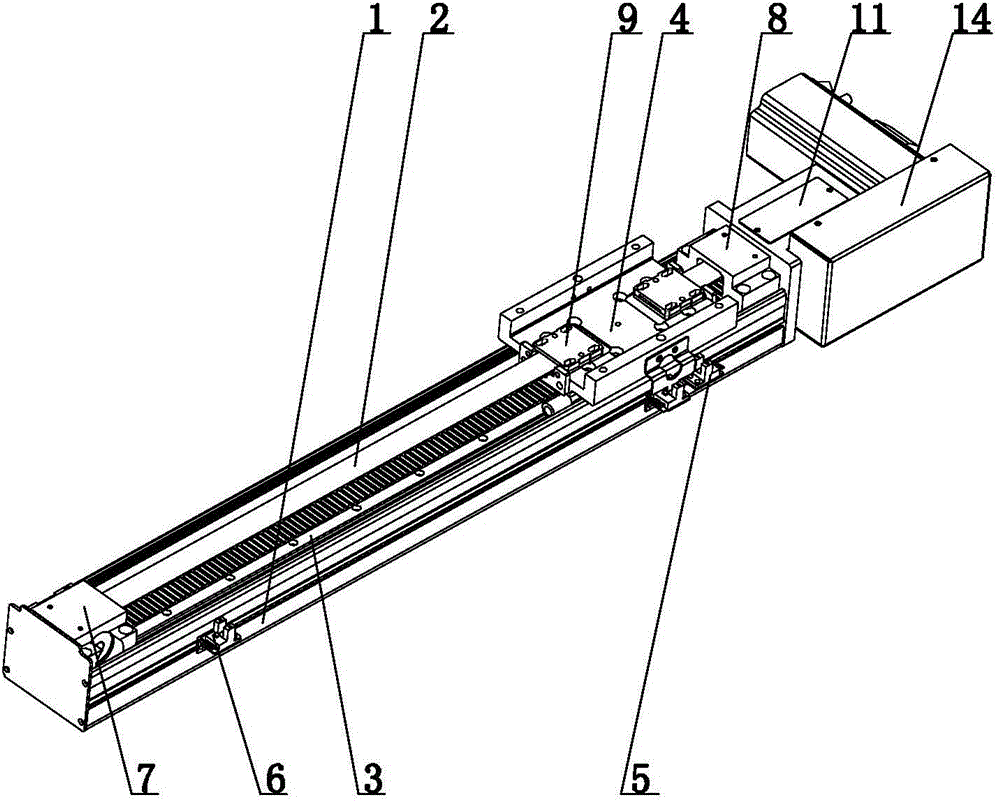

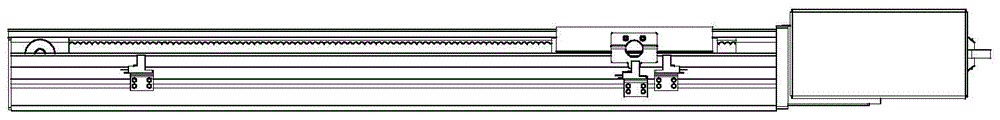

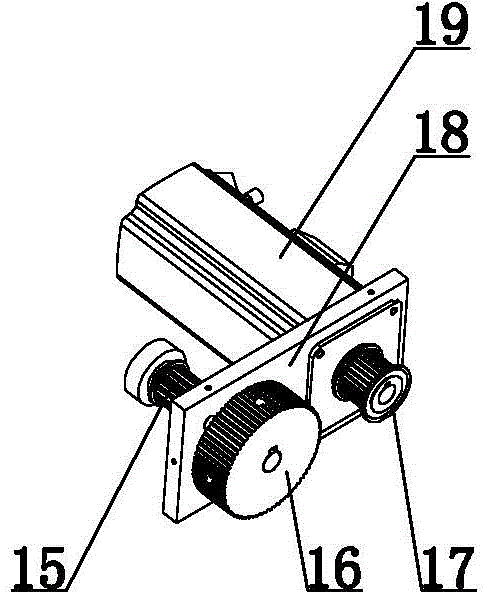

[0018] like figure 1 , 2 , The electronic sliding table shown in 3 and 4 includes a sliding table base 1, a guide rail 3 is provided on the sliding table base 1, a slidable sliding fixed block structure is provided on the guide rail 3, and the two ends of the sliding table base 1 A front fixed block 7 and a rear fixed block 8 are respectively provided, and the rear fixed block 8 is connected with the tail end fixed block 11, and the tail end fixed block 11 is provided with a driving structure for driving the movable sliding fixed block structure, and the described sliding fixed block structure includes a sliding The fixed block 4, the driving structure includes a servo motor a19, the tail end fixed block 11 is connected with the motor fixed block 18, the motor fixed block 18 is provided with a servo motor a19, the servo motor a19 servo motor shaft is provided with a synchronous wheel a17, and the synchronous wheel a17 is the same There is a synchronous wheel b16 on the side, ...

Embodiment 2

[0021] like Figure 5 , 6 , 7, the difference between this embodiment and embodiment 1 is that the sliding and fixing block structure includes a sliding and fixing block 4, the driving structure includes a service motor a19, the tail end fixing block 11 is connected with the motor fixing block 18, and the motor fixing block 18 There is a servo motor a19 on the top, and the servo motor shaft of the servo motor a19 is provided with a synchronous wheel a17, and the same side of the synchronous wheel a17 is provided with a synchronous wheel b16, and a rotating belt is arranged between the synchronous wheel a17 and the synchronous wheel b16, and the synchronous wheel b16 passes through the motor Fixed block 18 is connected with synchronous wheel c15, and described synchronous wheel c15 is positioned at tail end fixed block 11, and cover block 13 is housed on back fixed block 8 and tail end fixed block 11, and casing 14 is housed on motor fixed block 18, front fixed The block 7 is ...

Embodiment 3

[0023] like Figure 8 , 9 , 10, the difference between this embodiment and Embodiment 1 is that the sliding and fixing block structure includes a sliding and fixing block 4, and the driving structure includes a servo motor b26, and the motor head of the servo motor b26 is connected to the screw rod 21 through a coupling 23, and the screw Rod 21 is located between front fixed block 7 and rear fixed block 8, and front fixed block 7 inwall is provided with buffer head 25, and sliding fixed block 4 is connected with screw mandrel 21 by guide rail slide block 29, and screw mandrel 21 is provided with screw mandrel. Nut 22.

[0024] During use, the sliding and fixing block 4 is driven to move back and forth by the screw mandrel 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com