Power generating element

A technology of power generation components and composite rods, which is applied in the direction of electrical components, generators/motors, circuits, etc., can solve problems such as difficult stress, and achieve the effect of improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

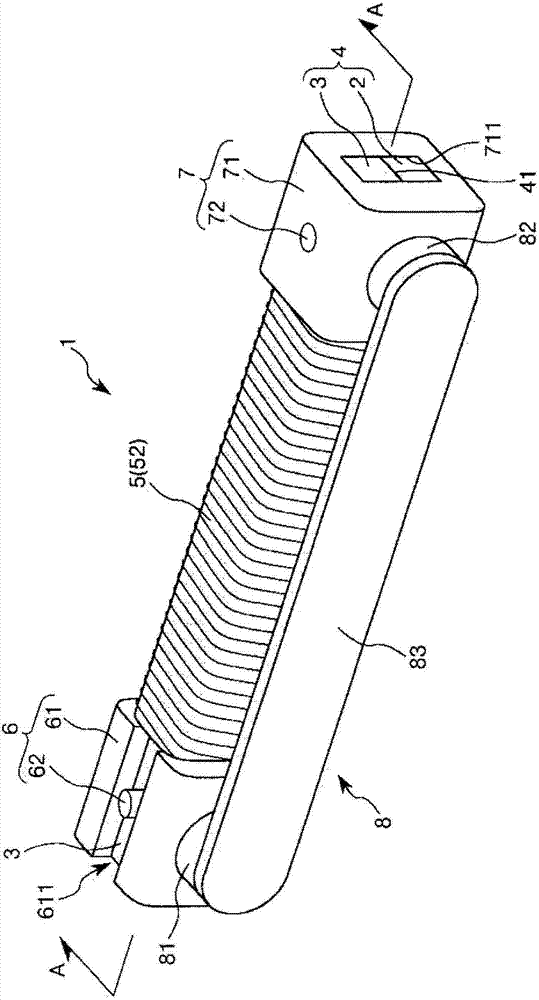

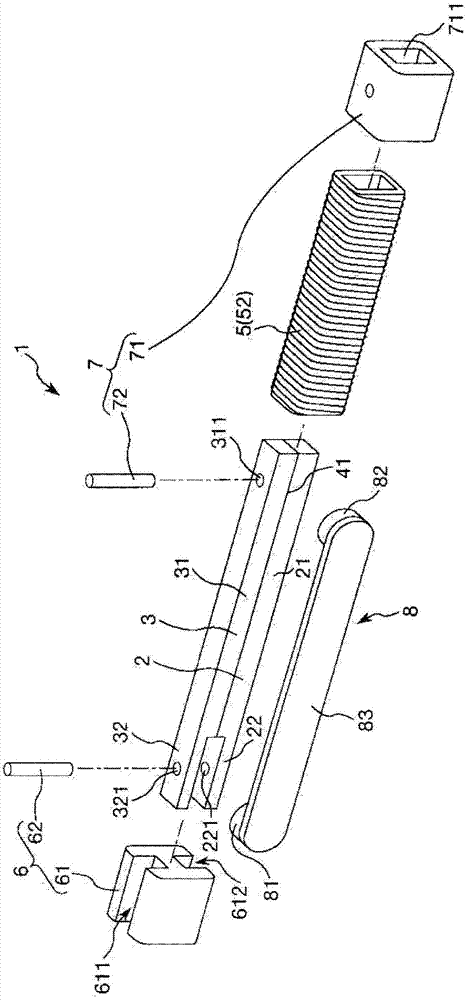

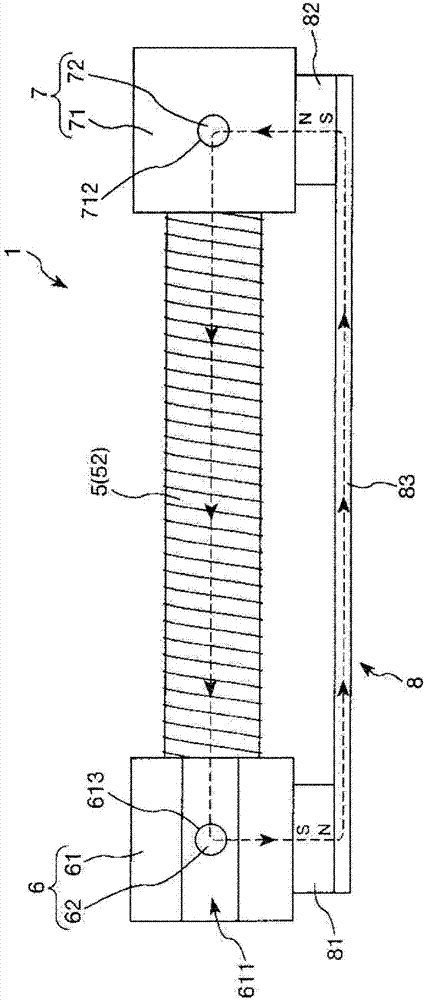

[0050] First, a first embodiment of the power generating element of the present invention will be described.

[0051] figure 1 It is a perspective view showing the first embodiment of the power generating element of the present invention, figure 2 yes figure 1 An exploded perspective view of the power generating element shown, image 3 yes figure 1 A top view of the generating element shown, Figure 4 yes figure 1 Longitudinal sectional view of the power generating element shown ( figure 1 A-A line sectional view in), Figure 5 It is an analytical diagram analyzing the stress generated in the composite rod.

[0052] Also, in the following description, the figure 1 , figure 2 as well as Figure 4 the upper side of the image 3 The front side of the paper is called "upper" or "above", and the figure 1 , figure 2 as well as Figure 4 the lower side of the middle and image 3 The inside of the paper is called "down" or "below". Additionally, the Figure ...

no. 2 approach >

[0113] Next, a second embodiment of the power generating element of the present invention will be described.

[0114] Figure 6 It is a longitudinal sectional view showing a second embodiment of the power generating element of the present invention.

[0115] Also, in the following description, the Figure 6 The upper side in is referred to as "upper" or "above", and the Figure 6 The lower side in is called "lower" or "below". Additionally, the Figure 6 The right side is called the "front end" and the left side is called the "base end".

[0116] Hereinafter, the power generating element of the second embodiment will be described focusing on points that are different from the power generating element of the first embodiment described above, and descriptions of the same matters will be omitted.

[0117] The power generating element 1 of the second embodiment is the same as the power generating element 1 of the above-mentioned first embodiment except that the overall shape ...

no. 3 approach >

[0122] Next, a third embodiment of the power generating element of the present invention will be described.

[0123] Figure 7 It is a longitudinal sectional view showing a third embodiment of the power generating element of the present invention.

[0124] Also, in the following description, the Figure 7 The upper side in is called "upper" or "above", and the lower side is called "lower" or "below". Additionally, the Figure 7 The right side is called the "front end" and the left side is called the "base end".

[0125] Hereinafter, the power generating element of the third embodiment will be described focusing on points that are different from the power generating elements of the first and second embodiments described above, and descriptions of the same matters will be omitted.

[0126] In the power generating element 1 of the third embodiment, the relationship between the thickness of the main body portion 21 of the magnetostrictive rod 2 and the thickness of the main bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com